Technically, there is no such thing as an "OSHA approved" boot. The Occupational Safety and Health Administration (OSHA) does not test, certify, or approve any specific brand or model of footwear. Instead, OSHA requires employers to ensure workers use protective footwear that meets or exceeds performance standards developed by ASTM International (formerly the American Society for Testing and Materials).

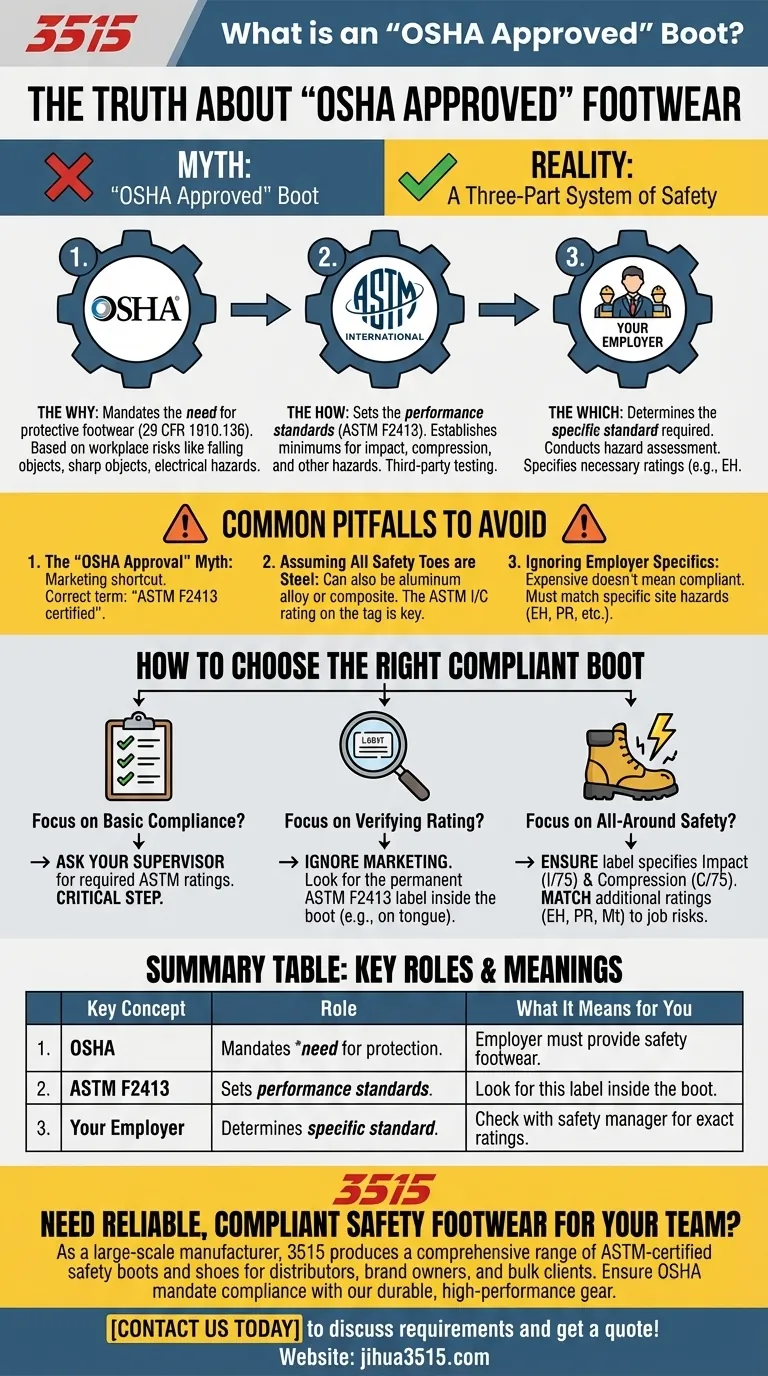

The core misunderstanding is the term "OSHA approved." The reality is a three-part system: OSHA mandates the need for safety footwear, ASTM sets the performance standards for that footwear, and your employer determines the specific standard required for your job's hazards.

The Roles Explained: OSHA vs. ASTM

To select the right footwear, you must understand who is responsible for what. These roles are distinct and work together to ensure your safety.

OSHA's Role: The "Why"

OSHA is the government agency responsible for setting and enforcing workplace safety standards.

OSHA's regulations, specifically 29 CFR 1910.136, mandate that employers require protective footwear when employees face risks of foot injuries. These risks include falling objects, rolling equipment, sharp objects, or electrical hazards.

Essentially, OSHA defines why and when you need safety boots.

ASTM's Role: The "How"

ASTM International is a standards organization that defines how a boot must perform to be considered protective.

The primary standard for safety footwear is ASTM F2413. This standard establishes the minimum performance requirements for impact resistance, compression resistance, and other specific hazards.

A boot that meets these criteria is tested by a third-party lab and can then be labeled as ASTM F2413-compliant. This label is the true mark of a safety-rated boot.

The Employer's Role: The "Which"

Your employer is responsible for conducting a hazard assessment of your specific workplace.

Based on this assessment, your employer must determine which specific ASTM protections are necessary for your job. For example, an electrician needs boots with an Electrical Hazard (EH) rating, while a roofer might need a Puncture Resistant (PR) sole.

Common Pitfalls to Avoid

Navigating safety standards can be confusing, and common misconceptions can lead to non-compliance or inadequate protection.

The Myth of "OSHA Approval"

Manufacturers often use the term "OSHA approved" or "OSHA compliant" as a marketing shortcut.

While not intentionally deceptive, this language is imprecise. The technically correct statement is that the boot is "ASTM F2413 certified," which in turn helps you meet OSHA's requirements.

Assuming All Safety Toes are Steel

The defining feature of a safety boot is its protective toe cap, which must meet ASTM standards for impact (I) and compression (C).

These caps can be made of steel, but also of lighter materials like aluminum alloy or non-metallic composites. The material is less important than its certified ASTM I/C rating, which will be printed on the boot's tag.

Ignoring Your Employer's Specifics

Buying the most expensive, highly-rated boot on the market does not guarantee compliance.

If your job site has specific electrical or puncture hazards, a standard steel-toe boot without the proper EH or PR rating will not be sufficient. Always start with the requirements provided by your employer.

How to Choose the Right Compliant Boot

Use this framework to ensure you select footwear that provides both safety and compliance.

- If your primary focus is basic compliance: Start by asking your supervisor or safety manager for the specific ASTM ratings required for your role. This is the most critical first step.

- If your primary focus is verifying a boot's rating: Ignore the marketing on the box and look for the permanent label sewn inside the boot, typically on the tongue. It must clearly state "ASTM F2413" along with the specific performance ratings.

- If your primary focus is all-around safety in a hazardous environment: Ensure the boot's label specifies both impact resistance (I/75) and compression resistance (C/75), and then look for additional ratings (like EH, PR, Mt) that match your specific job site risks.

Understanding these standards empowers you to choose footwear that not only meets regulations but truly protects you on the job.

Summary Table:

| Key Concept | Role | What It Means for You |

|---|---|---|

| OSHA | Mandates the need for protection. | Your employer must provide safety footwear for workplace hazards. |

| ASTM F2413 | Sets the performance standards. | Look for this label inside the boot for certified impact, compression, and other protections. |

| Your Employer | Determines the specific standard required. | Always check with your safety manager for the exact ratings (EH, PR, etc.) needed for your job. |

Need Reliable, Compliant Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring your workforce meets OSHA mandates with durable, high-performance gear.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Injection Athletic Style Safety Shoes

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What potential foot injury hazards exist in workplaces? A Guide to Mitigating Common Risks

- How does repeated exposure to high temperatures damage safety boots? Avoid Costly Structural Failures

- What are the advantages of rubber soles in safety boots? Unbeatable Grip & Durability

- What is the impact of incorrect specification on safety boots? Avoid Costly Injuries and Non-Compliance

- What are the signs that safety toe boots are worn out and need replacement? Ensure Your Workplace Safety