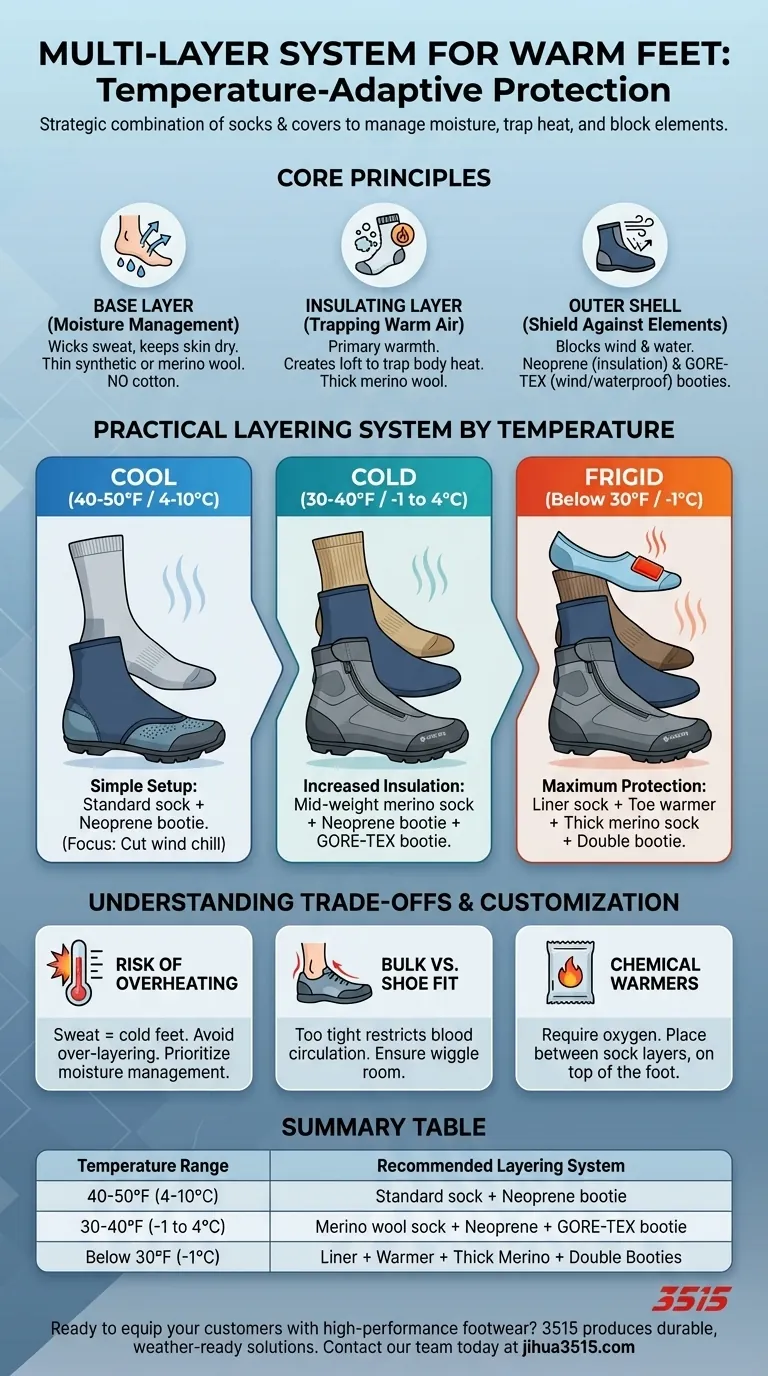

A multi-layer system for keeping feet warm is a strategic combination of socks and protective covers, adjusted for specific temperature ranges. For temperatures in the 40s (°F), a standard sock with a neoprene bootie is effective. As it drops into the 30s, this is upgraded to a wool sock, a neoprene bootie, and an additional GORE-TEX bootie. For frigid conditions in the 20s or below, the system involves a thin liner sock, a chemical toe warmer, a thicker wool sock over it, and the same double-bootie setup.

The goal of a layering system is not just to add insulation, but to actively manage moisture from the inside and block wind and water from the outside. A dry foot is a warm foot, and piling on the wrong layers can be counterproductive.

The Core Principles of a Layering System

To build a system that works for you, it's crucial to understand the distinct role each layer plays. The concept moves beyond just thickness and focuses on function.

The Base Layer: Moisture Management is Key

Your innermost sock has one primary job: wick sweat away from your skin. Moisture against the skin is the fastest way to lose heat.

A thin, snug-fitting sock made of a synthetic material or merino wool is ideal for this purpose. Cotton should be avoided at all costs, as it absorbs moisture and holds it against your skin.

The Insulating Layer: Trapping Warm Air

This is the layer that provides the primary warmth. Its job is to create loft—tiny air pockets that trap the heat your body generates.

A high-quality, thicker sock made from merino wool is the standard for this role. Wool is exceptional because it continues to insulate even when it gets damp.

The Outer Shell: Your Shield Against the Elements

The final layer protects your insulated foot from the external environment. Its purpose is to block wind and water.

This is typically a shoe cover or "bootie." A neoprene bootie offers excellent insulation, while a GORE-TEX (or similar) bootie provides superior wind and waterproofing. Using both offers maximum protection.

A Practical Layering System by Temperature

Based on these principles, here is a field-tested system that can be adapted to your specific activity and climate.

For Cool Days (40-50°F / 4-10°C)

At this range, the primary goal is to cut the wind chill. A simple setup is all that is required.

- Inside: A standard pair of cycling or running socks.

- Outside: A single neoprene bootie over your shoe.

For Cold Days (30-40°F / -1 to 4°C)

Here, you need to add insulation and increase your weather protection.

- Inside: A mid-weight merino wool sock.

- Outside: A neoprene bootie, with an additional waterproof/windproof shell bootie (like GORE-TEX) over it.

For Frigid Days (Below 30°F / -1°C)

This is a maximum protection setup designed to combat extreme cold and prevent numbness.

- Layer 1: A very thin liner sock directly against the skin.

- Layer 2: A chemical toe warmer placed on top of your toes, outside the liner sock.

- Layer 3: A thick merino wool sock over the liner and the warmer.

- Outside: The same double-bootie system (neoprene inner, shell outer).

Understanding the Trade-offs

Implementing a layering system is a balancing act. Being aware of the potential downsides is critical for success.

The Risk of Overheating and Sweat

The most common mistake is over-layering. If your feet get too hot, they will sweat profusely. This moisture will overwhelm your base layer and eventually make your feet colder than if you had worn less.

Bulk vs. Shoe Fit

Adding thicker socks and chemical warmers will take up more volume in your shoe. If your shoe becomes too tight, it can restrict blood circulation, which is essential for keeping your extremities warm. Always ensure you have enough room for your toes to wiggle.

The Limits of Chemical Warmers

Chemical warmers require oxygen to generate heat. Inside a cramped shoe and multiple bootie layers, their oxygen supply can be limited, reducing their effectiveness and lifespan. Placing them between sock layers, on top of the foot, often works best.

How to Customize Your System

Use the temperature guides as a starting point, but adjust based on your personal physiology and activity level.

- If your primary focus is high-intensity activity: Prioritize moisture management and start with one fewer layer than you think you need to avoid overheating.

- If your primary focus is long-duration, low-intensity endurance: Emphasize insulation and wind-blocking, as you will be generating less body heat over time.

- If you have naturally cold feet or a condition like Raynaud's: Be more aggressive with your system, introducing chemical warmers and double booties at warmer temperatures.

Ultimately, personal experimentation is the key to perfecting a system that keeps your feet warm and comfortable in any condition.

Summary Table:

| Temperature Range | Recommended Layering System |

|---|---|

| 40-50°F (4-10°C) | Standard sock + Neoprene bootie |

| 30-40°F (-1 to 4°C) | Merino wool sock + Neoprene bootie + GORE-TEX bootie |

| Below 30°F (-1°C) | Liner sock + Toe warmer + Merino wool sock + Double bootie system |

Ready to equip your customers with high-performance footwear for any condition?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, weather-ready footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots designed with the principles of warmth, moisture management, and protection in mind.

Contact our team today to discuss your manufacturing needs and provide your market with reliable cold-weather solutions.

Visual Guide

Related Products

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Durable Steel Toe Safety Boots Wholesale & Custom Manufacturing

- Wholesale Breathable Perforated Slip-On Loafers Custom Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How can you determine the correct boot size? A Step-by-Step Guide to a Perfect Fit

- Which organization regulates safety footwear requirements in industrial settings? Ensure OSHA & ASTM Compliance

- What is the strategic significance of utilizing locally manufactured footwear? Balance Local Roots & Global Appeal

- How do quality certification standards for safety shoes reduce perceived risk? Buy Online with Technical Certainty

- How does a comprehensive footwear portfolio meet industrial needs? Expert Solutions for Large-Scale Safety & Performance