In simple terms, a Goodyear welt is a superior method of shoe construction where a strip of leather is stitched to the upper part of the boot and the sole, creating an incredibly durable and water-resistant bond. Unlike cheaper methods where the sole is simply glued on, this stitched construction allows the boot to be repaired and resoled multiple times, dramatically extending its life.

The Goodyear welt is not just a feature; it's a construction philosophy. It transforms a boot from a disposable item into a long-term investment that can be rebuilt, offering unparalleled durability and value over its lifespan.

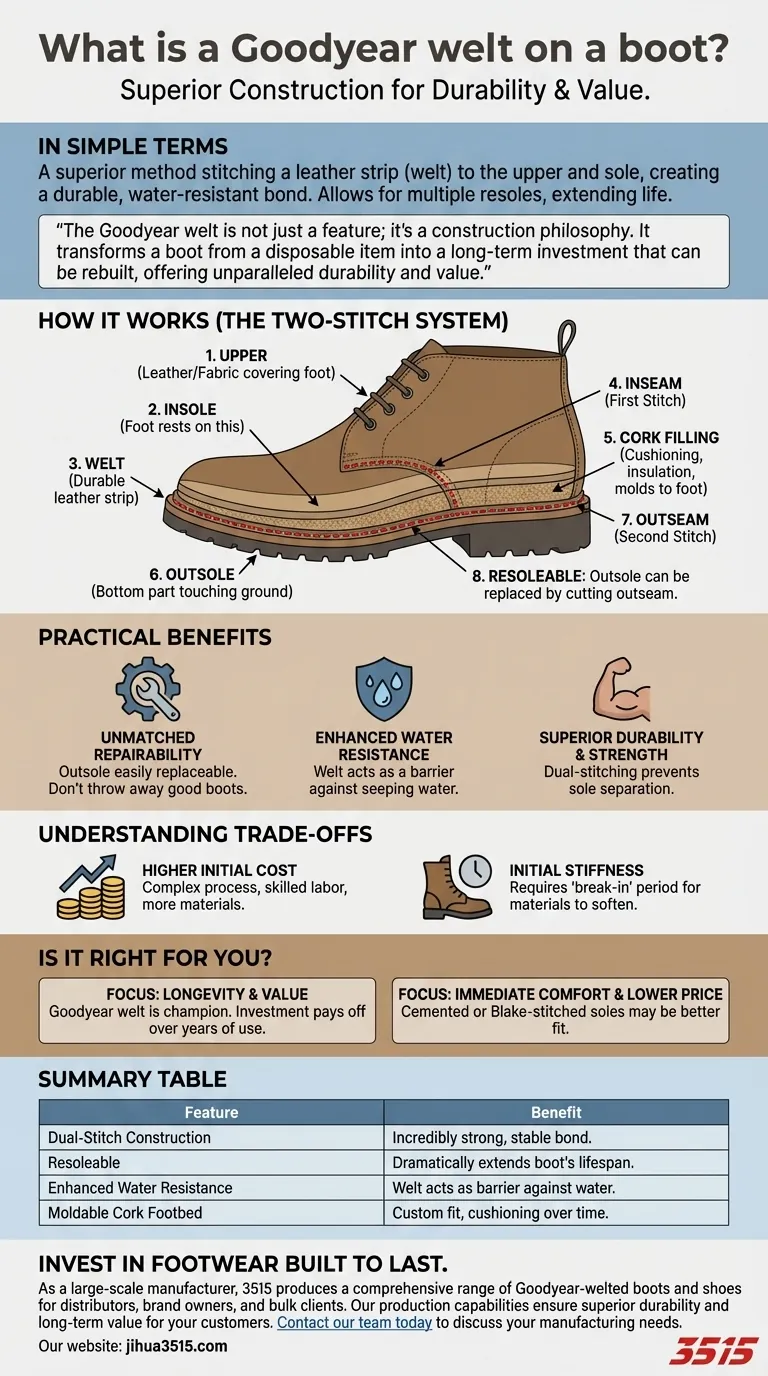

How a Goodyear Welt Works

To understand the benefit of a Goodyear welt, you must first understand how a boot is assembled. The process creates a secure, layered structure by connecting the key parts of the boot with two independent stitches.

The Key Components

A boot is made of three primary parts. The upper is the leather or fabric portion that covers your foot. The insole is what your foot rests on inside the boot. The outsole is the bottom part that makes contact with the ground.

The First Stitch (Inseam)

The process begins by stitching a durable strip of leather—the welt—to the boot's upper and a canvas rib attached to the insole. This first stitch, known as the inseam, creates a strong, unified cavity between the insole and the outsole.

Creating the Foundation

This cavity is typically filled with a layer of granulated cork. The cork provides cushioning, insulation, and, over time, molds to the shape of your foot, creating a custom-like fit.

The Second Stitch (Outseam)

Finally, the outsole is stitched directly to the welt using a separate, heavy-duty stitch called the outseam. This second stitch is what you can often see running along the outside edge of the sole on a well-made boot.

The Practical Benefits of This Construction

The two-level stitching system is what gives Goodyear-welted footwear its legendary reputation. The benefits are direct results of this meticulous construction.

Unmatched Repairability

Because the outsole is stitched only to the welt and not to the upper, a cobbler can easily cut the outseam stitch and attach a brand new sole. This resoleable nature means you don't have to throw away a perfectly good pair of boots just because the tread has worn down.

Superior Durability and Strength

The dual-stitching method creates an exceptionally strong and stable bond between all parts of the boot. This prevents the sole from delaminating or separating from the upper, even under heavy use.

Enhanced Water Resistance

The welt acts as a barrier, running along the perimeter of the boot and preventing water from easily seeping in between the upper and the midsole. While not fully waterproof, it provides significantly more protection than a simple glued construction.

Understanding the Trade-offs

No construction method is perfect for every situation. Being an informed buyer means recognizing the potential downsides of a Goodyear welt.

Higher Initial Cost

The Goodyear welting process is more complex, requires skilled labor, and uses more materials. This results in a higher upfront cost compared to boots with cemented (glued) soles.

Initial Stiffness

The multiple layers of leather, cork, and stitching make the boot quite rigid out of the box. Goodyear-welted boots famously require a "break-in" period as the leather and cork footbed soften and conform to your foot.

Is a Goodyear Welt Right for You?

Choosing the right boot construction depends entirely on your priorities and intended use.

- If your primary focus is longevity and long-term value: A Goodyear welt is the undisputed champion, as the ability to resole the boot means your initial investment pays off over many years of use.

- If your primary focus is immediate comfort and a lower price: A boot with a cemented or Blake-stitched sole may be a better fit, offering more flexibility and affordability for casual or less demanding wear.

Ultimately, choosing a Goodyear-welted boot is an investment in a product that is built to be maintained, not replaced.

Summary Table:

| Feature | Benefit |

|---|---|

| Dual-Stitch Construction | Creates an incredibly strong, stable bond between the upper and sole. |

| Resoleable | The outsole can be replaced, dramatically extending the boot's lifespan. |

| Enhanced Water Resistance | The welt acts as a barrier, preventing water from easily seeping in. |

| Moldable Cork Footbed | Provides cushioning and molds to the shape of your foot for a custom fit over time. |

Invest in footwear built to last. As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear-welted boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities ensure superior durability and long-term value for your customers. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What is the core function of professional safety boots within a construction Health and Safety (H&S) management system? Beyond Protection: Boost Safety & Productivity

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards