The single most important tip for maintaining slip resistance is recognizing that no shoe is completely slip-proof. True, lasting safety comes from a combination of cleaning your shoe's outsoles regularly and, most importantly, ensuring your work environment is kept clean and free of contaminants like water, oil, or debris.

Slip-resistant footwear is a critical safety tool, but its effectiveness is entirely dependent on the cleanliness of both the shoe's tread and the floor itself. Proactive maintenance of your gear and your environment is the ultimate strategy for preventing falls.

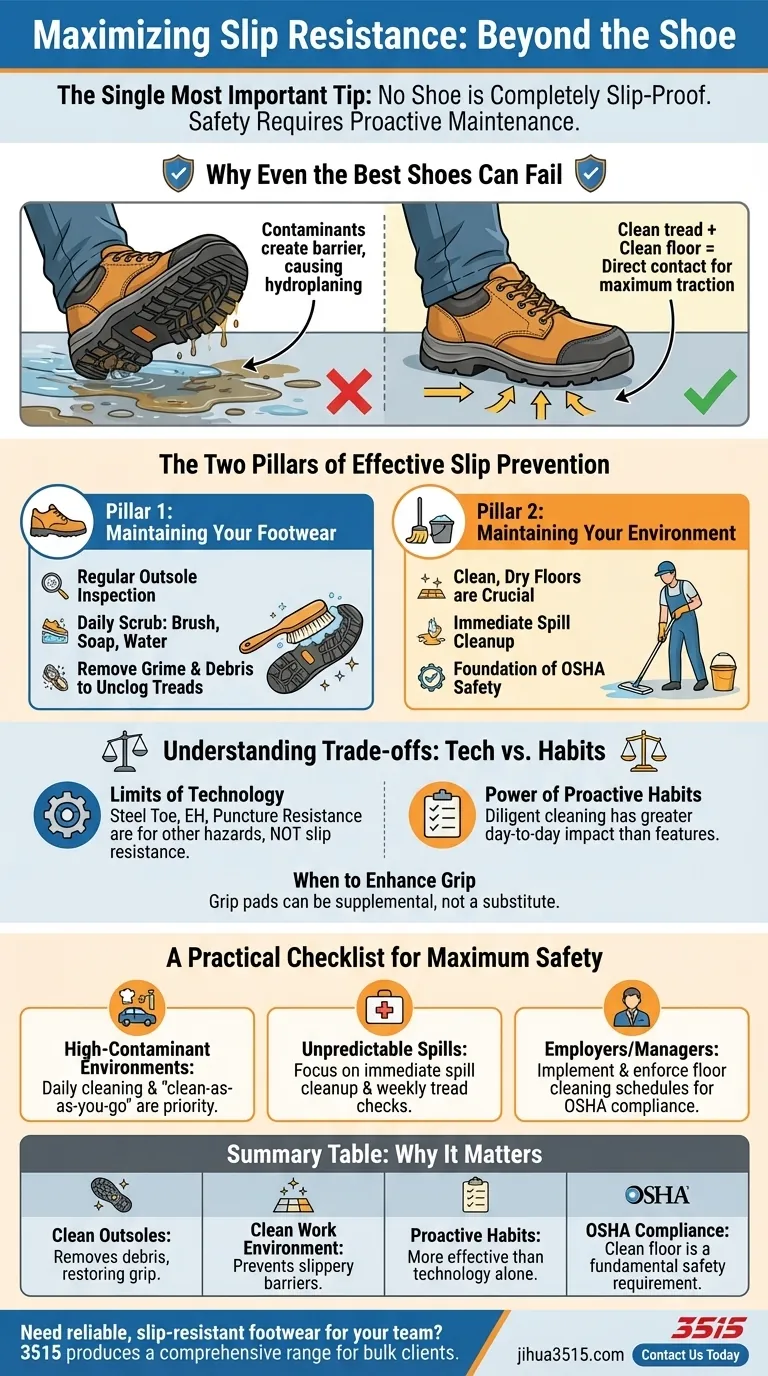

Why Even the Best Shoes Can Fail

Slip-resistant shoes are engineered to provide superior grip, but they operate on principles of friction that can be easily defeated. Understanding how they work clarifies why maintenance is so crucial.

The Principle of Traction

The outsoles of slip-resistant shoes feature specialized tread patterns designed to create a large surface area and channel liquids away from the bottom of the shoe. This allows the sole to make direct, firm contact with the floor, maximizing grip.

The Role of Contaminants

Water, grease, oil, and even fine dust create a barrier between the shoe’s outsole and the floor. When this happens, the shoe effectively "hydroplanes," losing the direct contact needed for traction, which is how slips occur.

The Impact of Clogged Treads

Over time, the channels in your shoe's tread can become clogged with dirt, grease, and other debris. When the tread is full, it can no longer channel away fluids, rendering the slip-resistant design ineffective.

The Two Pillars of Effective Slip Prevention

True workplace safety isn't just about the equipment you wear; it's about the system you operate within. This system relies on two equally important pillars.

Pillar 1: Maintaining Your Footwear

Regularly inspect and clean the outsoles of your work shoes. A quick scrub with a brush, soap, and water at the end of a shift can remove the grime that compromises the tread's effectiveness. Clean treads are effective treads.

Pillar 2: Maintaining Your Environment

The single greatest factor in preventing slips is a clean, dry floor. This is a core requirement of workplace safety regulations from bodies like OSHA. Proactive cleaning of spills and regular floor maintenance is non-negotiable for safety.

Understanding the Trade-offs

Simply buying a feature-rich shoe is not a complete solution. You must distinguish between features that protect from different hazards and the habits that prevent slips.

The Limits of Technology

Features like a steel toe, electrical hazard (EH) protection, or puncture resistance are essential for protecting against specific impacts and hazards. However, they do not contribute to a shoe's slip resistance.

The Power of Proactive Habits

Diligent cleaning habits have a greater day-to-day impact on preventing slips than any single feature of a shoe. A clean, basic slip-resistant shoe will outperform a dirty, high-end one on a contaminated surface.

When to Enhance Your Grip

In some industries, like food service, workers may add grip pads to their shoes. While these can provide a temporary boost in traction, they are a supplemental measure, not a substitute for the fundamental pillars of clean shoes and clean floors.

A Practical Checklist for Maximum Safety

Apply these principles based on your specific role and environment to ensure you are effectively minimizing risk.

- If you work in a high-contaminant environment (e.g., kitchens, auto shops): Make daily outsole cleaning and rigorous "clean-as-you-go" floor policies your highest priority.

- If you work in an environment with unpredictable spills (e.g., healthcare): Focus on immediate spill cleanup and perform a weekly inspection and cleaning of your shoe treads.

- If you are an employer or safety manager: Your responsibility is to implement and enforce cleaning schedules for floors, as this is the foundation of OSHA compliance and worker safety.

Ultimately, workplace safety is an active system of good habits, not just a product you can buy off a shelf.

Summary Table:

| Key Aspect | Why It Matters |

|---|---|

| Clean Outsoles | Removes debris that clogs treads, restoring grip. |

| Clean Work Environment | Prevents contaminants from creating a slippery barrier. |

| Proactive Habits | More effective than relying on shoe technology alone. |

| OSHA Compliance | A clean floor is a fundamental safety requirement. |

Need reliable, slip-resistant footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots designed for demanding environments. We combine durable materials with advanced tread patterns to deliver superior grip, helping you build a safer workplace.

Contact us today to discuss your footwear needs and enhance your safety program!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

People Also Ask

- What are the EN ISO 20345 norms for safety shoes? A Guide to Choosing the Right Protection

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- What should warehouse work shoes include for safety? Essential Features for All-Day Protection

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- What types of workplace hazards require protective footwear? Essential Guide for Workplace Safety