To ensure worker safety, OSHA’s protective footwear requirements are not defined by a simple list of industries, but by the presence of specific workplace hazards. However, these hazards are most common in sectors like construction, manufacturing, warehousing, healthcare, food service, and hospitality, making compliance in these fields a critical priority.

The core principle of OSHA's standard is not about your industry title, but about the specific foot hazards your employees face. If there is a risk of injury from falling objects, punctures, or electrical dangers, protective footwear that meets ASTM standards is mandatory.

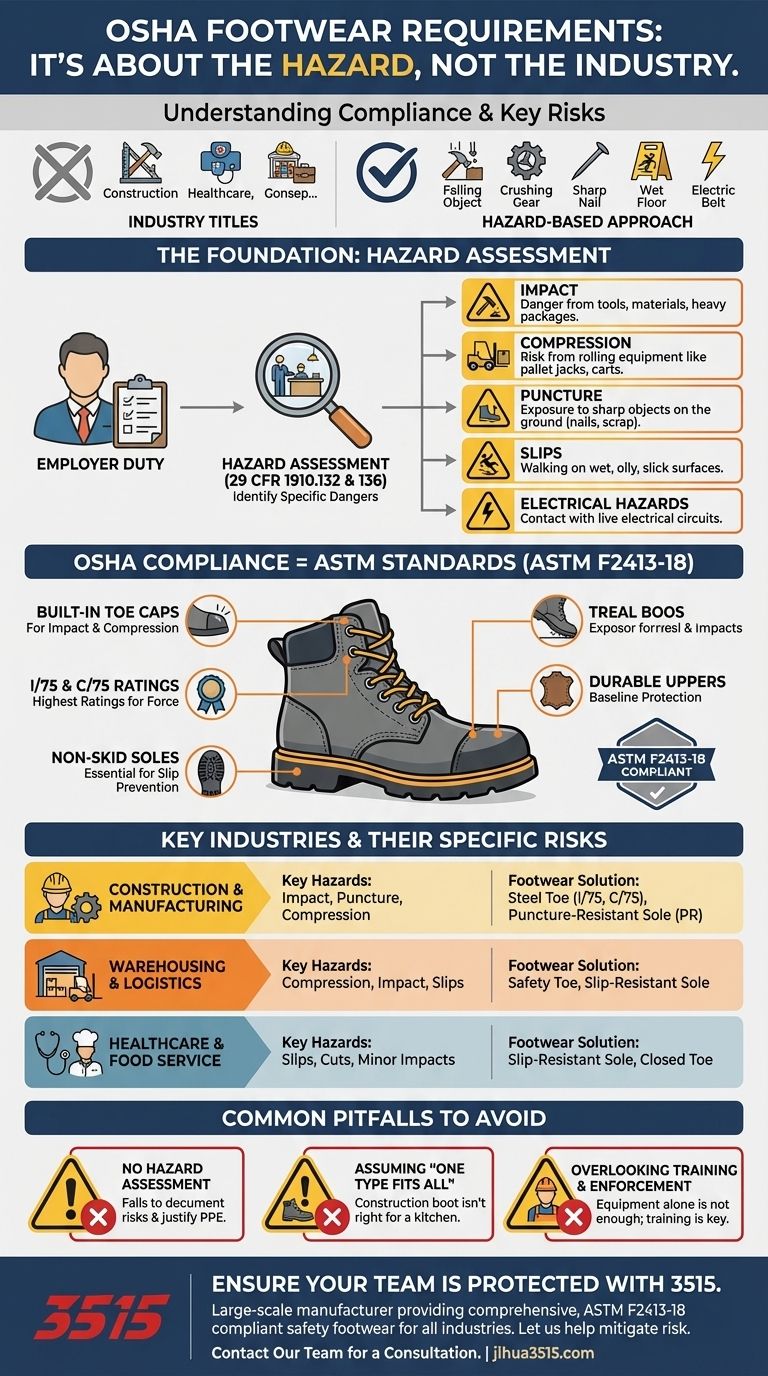

The "Why" Behind the Rule: It's About the Hazard, Not the Industry

OSHA's approach to personal protective equipment (PPE) is based on a universal principle: the employer is responsible for identifying and mitigating workplace hazards. This is the foundation for all footwear requirements.

The General Duty of Assessment

The relevant OSHA standards (29 CFR 1910.132 and 1910.136) require employers to perform a formal hazard assessment of their workplace. This assessment determines if employees are exposed to dangers that necessitate protective footwear.

Identifying Common Foot Hazards

Your industry likely requires protective footwear if your employees face any of the following risks:

- Impact: Danger from falling objects, such as tools, materials, or heavy packages.

- Compression: Risk of feet being crushed by rolling equipment like pallet jacks, carts, or forklifts.

- Puncture: Exposure to sharp objects on the ground, such as nails, scrap metal, or glass.

- Slips: Walking on surfaces that are frequently wet, oily, or otherwise slick.

- Electrical Hazards: Working in areas where contact with live electrical circuits is possible.

What Makes Footwear "OSHA-Compliant"?

OSHA does not certify specific brands of shoes. Instead, it mandates that protective footwear must meet or exceed the performance standards set by an independent organization, ASTM International.

The Role of ASTM Standards

The current governing standard is ASTM F2413-18. Footwear that complies with this standard has been tested for safety under the methods outlined in ASTM F2412-18a. Compliant footwear will be clearly marked with its specific safety ratings.

Core Protective Features

To be considered protective under these standards, footwear must include several key features:

- Built-in Toe Caps: This is a non-negotiable feature for protection against impact and compression.

- Impact & Compression Ratings: The highest rating is "I/75" for impact and "C/75" for compression, indicating it can withstand significant force.

- Non-Skid Soles: Essential for environments where slips and falls are a primary concern.

- Durable Uppers: Materials like leather provide a baseline of protection against splashes and minor scrapes.

Specialized Protections for Specific Environments

Depending on the hazard assessment, footwear may also need additional features like puncture resistance (PR), which is critical on construction sites, or protection against electrical hazards (EH).

A Closer Look at Key Industries and Their Risks

While the rule is hazard-based, certain industries inherently contain these hazards more than others.

Construction and Manufacturing

These environments present clear risks of impact from falling tools or materials and puncture from nails and debris on the ground. Steel-toed, puncture-resistant boots are standard.

Warehousing and Logistics

The primary risks here are compression from heavy rolling equipment (forklifts, pallet jacks) and impact from dropped inventory. Safety-toed footwear is essential.

Healthcare and Food Service

The most prevalent hazard is slips from wet or contaminated floors. Certified, non-skid soles are the top priority, with toe protection being important for risks like dropped equipment or sharp instruments.

Hospitality, Schools, and Supermarkets

Similar to healthcare, the main concern in these areas is slip resistance. Protecting against rolling carts and minor falling objects also makes safety footwear a common requirement.

Common Pitfalls to Avoid

Simply buying a pair of steel-toed boots is not enough to guarantee compliance or safety. True diligence requires a more thorough approach.

The Hazard Assessment is Non-Negotiable

Failing to conduct and document a formal hazard assessment is a common misstep. This document is your proof that you have analyzed the risks and selected the appropriate PPE for your team.

Assuming One Type Fits All

The right boot for a construction worker is different from the right shoe for a kitchen staff member. Using your hazard assessment, you must select footwear with the specific features—slip resistance, puncture resistance, etc.—that match your workplace's unique risks.

Overlooking Training and Enforcement

An effective safety program requires more than just providing the equipment. Employers must also train employees on why the footwear is necessary and consistently enforce its use.

Making the Right Choice for Your Workplace

Your selection process should be guided by a clear understanding of your primary safety goal.

- If your primary focus is heavy industry (Construction, Manufacturing): Prioritize footwear with the highest impact and compression ratings (I/75, C/75) and a puncture-resistant sole.

- If your primary focus is preventing slips and falls (Healthcare, Food Service): Your most critical feature is a certified, non-skid sole specifically designed for wet or oily surfaces.

- If your primary focus is a dynamic environment (Warehousing, Logistics): Seek a balance of impact/compression protection for the toes and reliable slip resistance for moving through the facility.

- If your primary focus is absolute compliance: Begin with a formal, written hazard assessment to justify every footwear decision you make, ensuring each choice aligns with the specific ASTM F2413-18 standard.

Ultimately, compliant footwear is a direct and necessary investment in the safety and stability of your workforce.

Summary Table:

| Industry | Common Hazards | Key Footwear Features |

|---|---|---|

| Construction & Manufacturing | Impact, Puncture, Compression | Steel Toe (ASTM I/75, C/75), Puncture-Resistant Sole |

| Warehousing & Logistics | Compression, Impact, Slips | Safety Toe, Slip-Resistant Sole |

| Healthcare & Food Service | Slips, Cuts, Minor Impacts | Slip-Resistant Sole, Closed Toe |

| General Hazard Assessment | Varies by specific tasks | Must meet ASTM F2413-18 standard for identified risks |

Ensure your team is fully protected and OSHA-compliant.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. We can provide the exact OSHA-compliant boots and shoes your workforce needs—from steel-toed boots for construction to slip-resistant shoes for kitchens—all meeting ASTM F2413-18 standards.

Let us help you mitigate risk and protect your employees. Contact our team today for a consultation on your specific safety footwear requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why is leather the preferred material for fire boots? Unmatched Heat Resistance & Durability

- What are the key requirements for NFPA-certified fire boots? Ensuring Maximum Firefighter Safety

- What types of midsoles are available in these boots? Choose Between Steel or Non-Metallic Protection

- What are the disadvantages of microfibre in safety shoes? Weighing Breathability vs. Durability

- What role do slip-resistant safety shoes play in high-risk environments? Essential Protection for Industrial Safety

- What are the different safety classes under the EN ISO 20345 standard? A Guide to S1, S2, S3, S4, S5

- What is the function of the shank in a safety boot? The Key to Arch Support & Stability

- How does physical conditioning assist tactical personnel in adapting to heavy safety shoes and boots?