At its core, protective footwear is a non-negotiable requirement in any industry where foot injuries are a significant risk. The most common sectors include construction, manufacturing, warehousing, and skilled trades such as auto repair, welding, and landscaping. These environments present daily hazards from falling objects, rolling equipment, sharp materials, and electrical currents, making certified safety footwear an essential component of personal protective equipment (PPE).

The specific industry is less important than the specific hazards present in the work environment. The key is to match the footwear's protective features—such as impact resistance, puncture-proofing, or electrical insulation—to the tangible risks of the job.

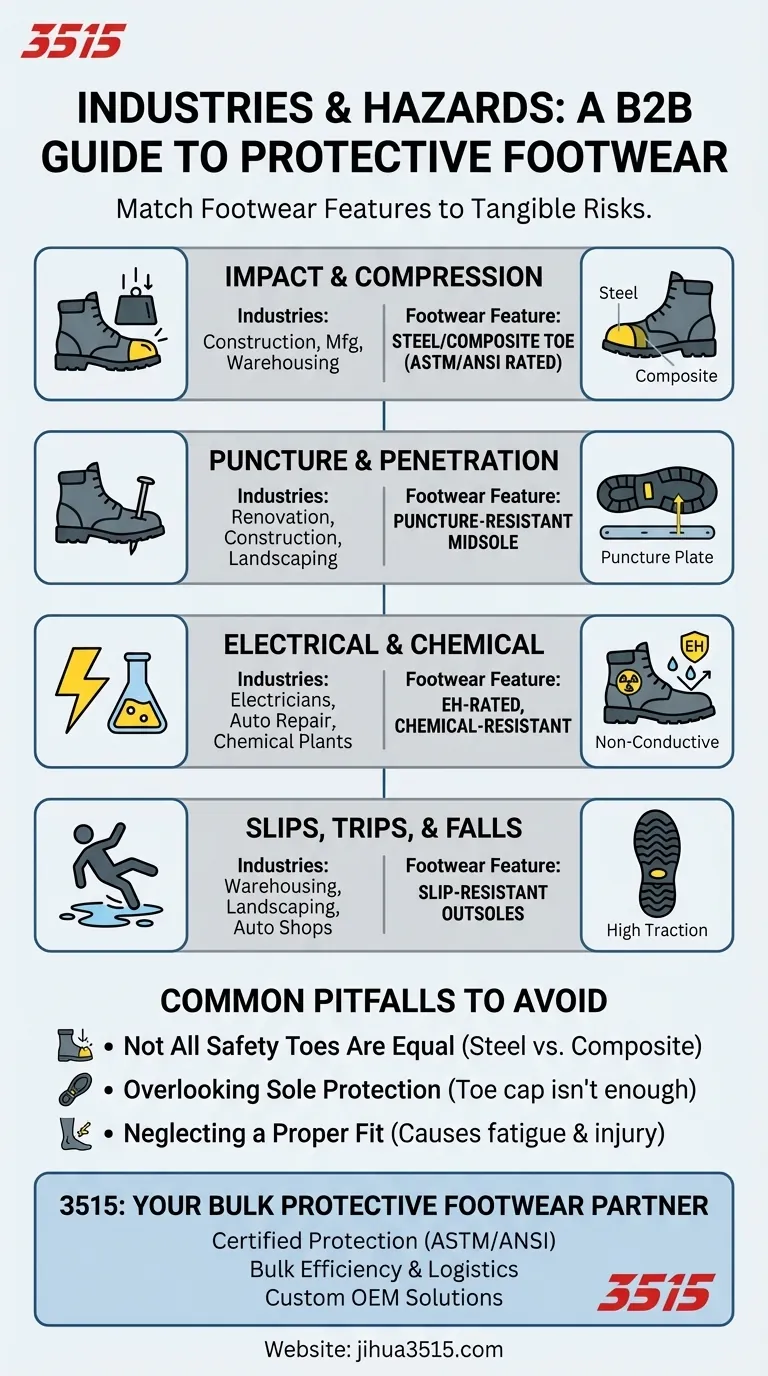

The Core Risks Driving Footwear Requirements

Understanding why safety footwear is mandated comes down to mitigating a few key categories of workplace hazards. The statistics are clear: contact with objects and equipment, along with slips, trips, and falls, are among the leading causes of preventable workplace injuries.

Impact and Compression Hazards

This is the most recognized risk. It involves the danger of heavy objects falling or rolling onto the foot.

Industries at risk: Construction, manufacturing, and warehousing are primary examples. Dropped tools, building materials, or the movement of forklifts and pallet jacks create constant compression and impact threats.

Puncture and Penetration Hazards

This risk involves sharp objects on the ground that could pierce the sole of a standard shoe.

Industries at risk: Renovation and construction sites are often littered with nails and screws. Commercial kitchens face risks from dropped knives, and landscaping environments can hide sharp rocks or debris.

Electrical and Chemical Hazards

Certain roles expose workers to the risk of electric shock or contact with corrosive substances.

Industries at risk: Electricians and maintenance workers require non-conductive footwear, often made with composite materials. Workers in manufacturing or auto repair may need boots resistant to oils, chemicals, and acids.

Slips, Trips, and Falls

This is one of the most common causes of injury across nearly all manual labor industries.

Industries at risk: Landscapers working on wet grass, auto mechanics on oily floors, and warehouse employees on smooth concrete all rely on high-traction, slip-resistant soles to maintain their footing and prevent serious injury.

Common Pitfalls to Avoid

Simply wearing a "safety boot" is not enough. Choosing the wrong type of protection can provide a false sense of security and leave a worker exposed to specific environmental risks.

Assuming All Safety Toes are Equal

A steel toe offers maximum impact protection, but a composite toe is non-metallic, making it ideal for electricians or workers in high-security environments. Composite toes do not conduct electricity, heat, or cold.

Overlooking Sole Protection

The toe cap protects from above, but the sole protects from below. A puncture-resistant plate is critical on demolition sites or in environments with sharp debris on the floor.

Neglecting a Proper Fit

An ill-fitting boot can cause blisters, fatigue, and long-term musculoskeletal issues. It's particularly important to consider footwear designed for a user's specific anatomy, as proper fit ensures both safety and all-day comfort.

Making the Right Choice for Your Goal

Your choice of protective footwear should be a direct response to the specific, daily risks of your job.

- If your primary focus is protection from falling objects or rolling carts: Prioritize a certified steel or composite toe for maximum impact and compression resistance.

- If your primary focus is working near live electrical circuits: Insist on footwear with an Electrical Hazard (EH) rating and a non-conductive composite toe.

- If your primary focus is navigating sites with sharp debris: Ensure your boots have a built-in puncture-resistant plate to protect the soles of your feet.

- If your primary focus is stability on wet, oily, or uneven surfaces: Look for a boot with a certified, high-traction slip-resistant outsole.

Ultimately, selecting the correct protective footwear is a foundational step in ensuring your safety and effectiveness at work.

Summary Table:

| Hazard Type | Key Industries | Required Footwear Feature |

|---|---|---|

| Impact/Compression | Construction, Manufacturing, Warehousing | Steel/Composite Toe (ASTM/ANSI rated) |

| Puncture/Penetration | Renovation, Construction, Landscaping | Puncture-Resistant Midsole |

| Electrical/Chemical | Electricians, Auto Repair, Chemical Plants | EH-rated, Chemical-Resistant Materials |

| Slips/Trips/Falls | Warehousing, Landscaping, Auto Shops | Slip-Resistant Outsoles |

Need Reliable Protective Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes and boots tailored to your industry's specific hazards—from steel-toe boots for construction to EH-rated footwear for electricians.

We ensure:

- Certified Protection: All footwear meets or exceeds relevant safety standards (ASTM, ANSI).

- Bulk Efficiency: Streamlined logistics and competitive pricing for large orders.

- Custom Solutions: OEM services available to match your brand's specifications.

Protect your workforce with footwear built for real-world risks. Contact our team today to discuss your requirements and request a catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- Why must safety training be synchronized with the provision of physical safety shoes? Achieve Optimal Workplace Protection

- Why is puncture-resistant technology critical for industrial safety shoes? Protect Workers with High-Strength Barriers

- What does the infographic mentioned in the article cover? Prevent Workplace Foot Injuries with the Right Safety Footwear

- What is the core design logic behind hybrid lattice structures? Unlock Multi-Material Synergistic Impact Protection

- What features should manufacturing workers consider for comfort in their protective footwear? Prioritize Support & Safety

- What specific safety functions do high-performance safety shoes provide for workers? Protect Your Team on-Site

- What are composite toe work boots and what are their benefits? Lightweight, Non-Conductive Safety Footwear

- How do professional safety shoes contribute to safety in manual handling? 5 Key Benefits for Construction Safety