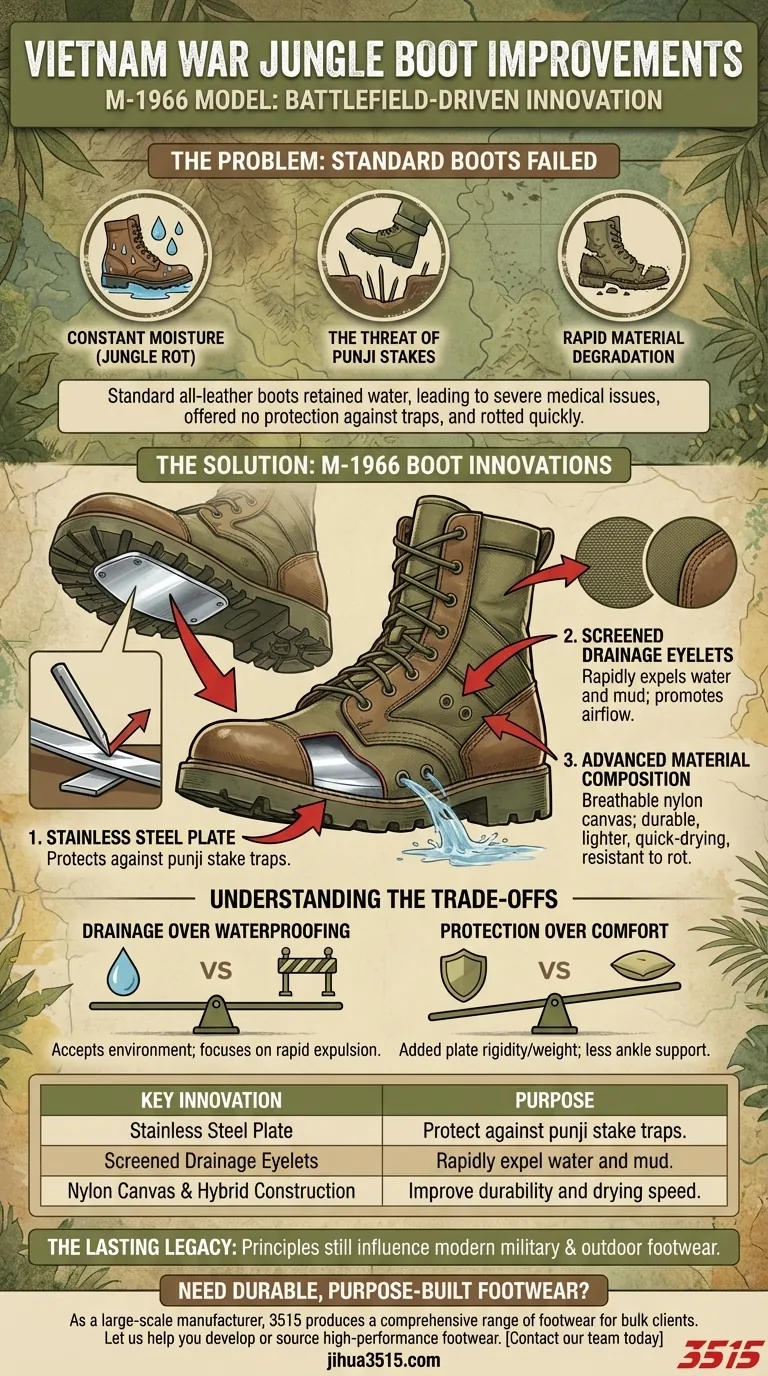

The primary improvements to the jungle boot during the Vietnam War were the direct result of battlefield experience. The M-1966 model introduced three critical innovations: a stainless steel plate in the sole to protect against punji stake traps, screened drainage eyelets to rapidly expel water and mud, and a shift to more durable, quick-drying materials like nylon canvas.

The evolution of the jungle boot was not about creating a waterproof piece of footwear. Instead, it was a radical acceptance of the environment, focusing on draining water as quickly as it entered and protecting the soldier from specific, deadly threats underfoot.

The Problem: Why Standard Boots Failed in Vietnam

The initial footwear issued to soldiers, typically all-leather combat boots, proved disastrously unsuited for the jungle. They retained water, leading to severe medical issues, and offered no protection against guerrilla traps unique to the region.

Constant Moisture and "Jungle Rot"

Standard leather boots, once wet, stayed wet. This constant saturation led to immersion foot, also known as "jungle rot," a condition that caused skin to break down, leading to debilitating infections that could take a soldier out of action.

The Threat of Punji Stakes

One of the most common and effective booby traps was the punji stake—a sharpened bamboo or metal spike hidden in the ground. The thin soles of early boots offered no protection, and a single misstep could result in a crippling, infection-prone wound.

Rapid Material Degradation

The perpetual dampness and harsh terrain caused the leather and cotton stitching of standard-issue boots to rot, stretch, and fall apart at an accelerated rate, creating a constant logistical problem.

The Solution: Key Innovations of the M-1966 Boot

The M-1966 jungle boot was a purpose-built tool designed to overcome the specific failures of its predecessors. Each feature was a direct answer to a problem encountered in the field.

The Spike Protective Plate

The most significant innovation was the integration of a stainless steel plate into the sole. This thin layer of metal was specifically designed to stop the penetration of a punji stake, dramatically reducing the incidence of these debilitating foot injuries.

Integrated Drainage System

Engineers abandoned the goal of keeping water out. Instead, they focused on getting it out quickly. The M-1966 boot featured two screened brass eyelets on the instep, allowing water and mud to be expelled with each step, promoting airflow and helping the foot dry faster.

Advanced Material Composition

The boot's upper was constructed from breathable nylon canvas or cotton canvas with nylon reinforcements. Leather was used sparingly on the toe and heel for abrasion resistance. This hybrid construction was lighter, dried much faster, and resisted rot far better than an all-leather design.

Understanding the Trade-offs

The jungle boot's design was a masterclass in compromise, prioritizing features essential for that specific environment while sacrificing others.

Drainage Over Waterproofing

The core principle was to let water in and out. Unlike modern waterproof-breathable boots (like those with Gore-Tex), the jungle boot was designed to be fully saturated and then drain instantly. This was the only viable strategy for an environment with constant river crossings and monsoons.

Protection Over Comfort

While lighter than an all-leather boot, the addition of the steel plate added rigidity and weight. Furthermore, the canvas uppers offered significantly less ankle support than a traditional combat boot, increasing the risk of sprains on uneven terrain.

The Lasting Legacy of the Design

The principles behind the Vietnam-era jungle boot still influence military and outdoor footwear today. Understanding its purpose reveals key insights into environmental design.

- If your primary focus is historical accuracy: The M-1966 model is defined by its steel plate, drainage eyelets, and canvas/nylon upper, which set it apart from all previous and many subsequent designs.

- If your primary focus is practical design principles: The boot's key lesson is that in perpetually wet environments, rapid drainage and material durability are superior to futile attempts at waterproofing.

Ultimately, the jungle boot stands as a testament to how equipment must evolve to meet the severe demands of its environment.

Summary Table:

| Key Innovation | Purpose |

|---|---|

| Stainless Steel Plate | Protect against punji stake traps. |

| Screened Drainage Eyelets | Rapidly expel water and mud. |

| Nylon Canvas & Hybrid Construction | Improve durability and drying speed. |

Need Durable, Purpose-Built Footwear for Demanding Environments?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including specialized designs informed by historical performance and modern materials.

Let us help you develop or source high-performance footwear tailored to your specific needs. Contact our team today to discuss your project.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- What is the proper method to clean military boots? A Step-by-Step Guide to Maximize Longevity

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style

- What materials are commonly used to make combat boots? Discover the optimal blend for durability and performance.

- What is the historical significance of combat boots? From Battlefield Necessity to Cultural Icon