For true electrical hazard protection, your work boots must be EH-rated, meaning their entire construction is made from non-conductive materials like rubber or leather. This design must be certified to withstand 18,000 volts for one minute without conducting a current, and it must not have any external metal parts, including the safety toe.

The most critical feature is the EH (Electrical Hazard) rating itself. This label is not a general claim but a certification that the boot is manufactured and tested to a specific ASTM standard, serving as a secondary source of protection against accidental contact with live electrical circuits.

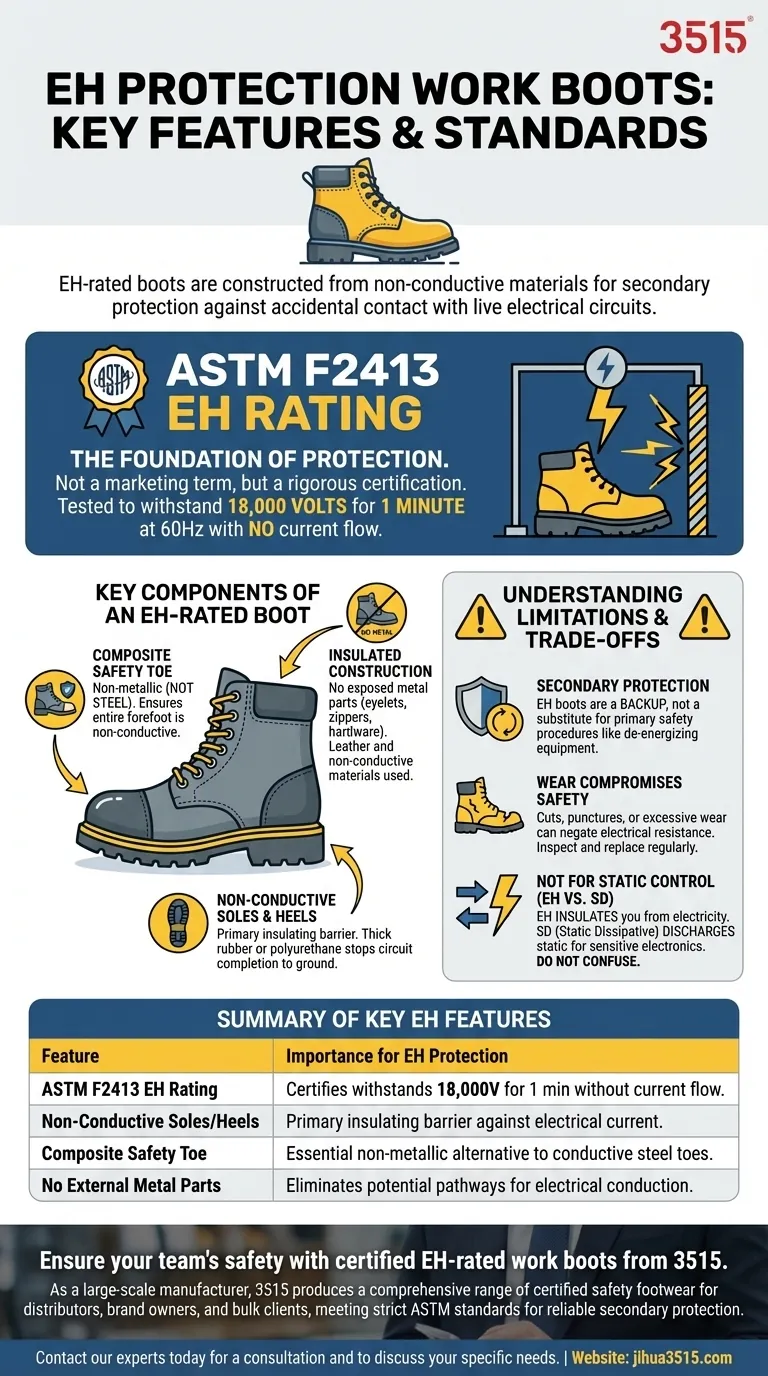

The Foundation of Protection: The EH Rating

To make an informed decision, you need to understand what the EH rating truly signifies. It’s a formal standard, not a marketing term, indicating a specific level of defense against a life-threatening risk.

What the EH Rating Guarantees

An EH rating certifies that the footwear provides a significant barrier to electric current. It's designed to protect the wearer from open circuits of 600 volts or less under dry conditions.

The ASTM Standard Explained

The specific standard is ASTM F2413. For a boot to earn this rating, it must withstand the application of 18,000 volts at 60 hertz for one full minute with no current flow or leakage to the foot. This rigorous test confirms the boot's insulating properties.

The Role of Non-Conductive Materials

The entire protective design relies on using materials that do not conduct electricity. The outsoles, heels, and shanks are made from materials like rubber, which act as insulators, stopping your body from completing an electrical circuit to the ground.

Key Components of an EH-Rated Boot

Several specific design elements work together to provide certified electrical hazard protection. Each component is chosen deliberately to eliminate conductive pathways.

Non-Conductive Soles and Heels

This is the primary barrier. A thick, properly manufactured sole and heel made of non-conductive rubber or polyurethane is the first and most critical line of defense.

Composite Safety Toes (Not Steel)

While a steel toe offers impact protection, it is a conductive material. For a boot to be properly EH-rated, any safety toe must be made from a non-metallic composite material. This ensures the entire forefoot area remains non-conductive.

Insulated Construction

Beyond the sole, the materials used in the boot's upper, such as leather, contribute to its overall insulating properties. No metal eyelets, zippers, or hardware should be exposed on the boot's exterior.

Understanding the Limitations and Trade-offs

Recognizing what EH-rated boots cannot do is just as important as knowing what they can. Over-reliance on them can create a false sense of security.

EH is a Secondary Source of Protection

This is the most critical point. EH boots are a backup, not a primary defense. They are not a substitute for proper safety procedures, insulated gloves, or de-energizing electrical equipment before work begins.

Wear and Tear Compromises Safety

The protective qualities of an EH boot depend on its integrity. Any deep cuts, punctures from nails, or excessive wear that exposes internal components can completely negate its electrical resistance. Boots must be regularly inspected and replaced if damaged.

Not for Static Control (EH vs. SD)

EH boots are designed to insulate you from electricity. This is the opposite of Static Dissipative (SD) boots, which are designed to safely discharge static electricity buildup from your body into the ground to protect sensitive electronic equipment. Using one where the other is required is a serious safety risk.

Making the Right Choice for Your Job

Your specific work environment dictates the exact features you need. Use these guidelines to select the appropriate footwear.

- If your primary risk is accidental contact with live circuits: Demand a boot that is clearly marked with an ASTM-certified EH rating.

- If you need impact protection in an EH environment: Always choose a boot with a composite toe, never a steel toe, to maintain its non-conductive properties.

- If you work around sensitive electronics or flammable materials: You likely need Static Dissipative (SD) boots, not EH boots, to prevent static discharge sparks.

Choosing the correct, certified footwear is a non-negotiable step in ensuring your personal safety on the job.

Summary Table:

| Key Feature | Importance for EH Protection |

|---|---|

| ASTM F2413 EH Rating | Certifies the boot can withstand 18,000 volts for one minute without current flow. |

| Non-Conductive Soles/Heels | Provides the primary insulating barrier against electrical current. |

| Composite Safety Toe | Essential non-metallic alternative to conductive steel toes. |

| No External Metal Parts | Eliminates potential pathways for electrical conduction. |

Ensure your team's safety with certified EH-rated work boots from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of EH-rated boots designed to meet strict ASTM standards, providing reliable secondary protection against electrical hazards.

Let us help you equip your workforce with the right protection. Contact our experts today for a consultation and to discuss your specific needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites