The most effective work shoes for wet conditions rely on a combination of features, not just a single material. The key elements are an internal waterproof membrane, a water-resistant upper material, and a specific boot construction that seals off common points of entry for moisture.

The challenge of keeping feet dry is twofold: you must block external water from getting in while simultaneously allowing internal moisture—sweat—to get out. The best systems achieve this balance through a waterproof yet breathable membrane combined with sealed construction.

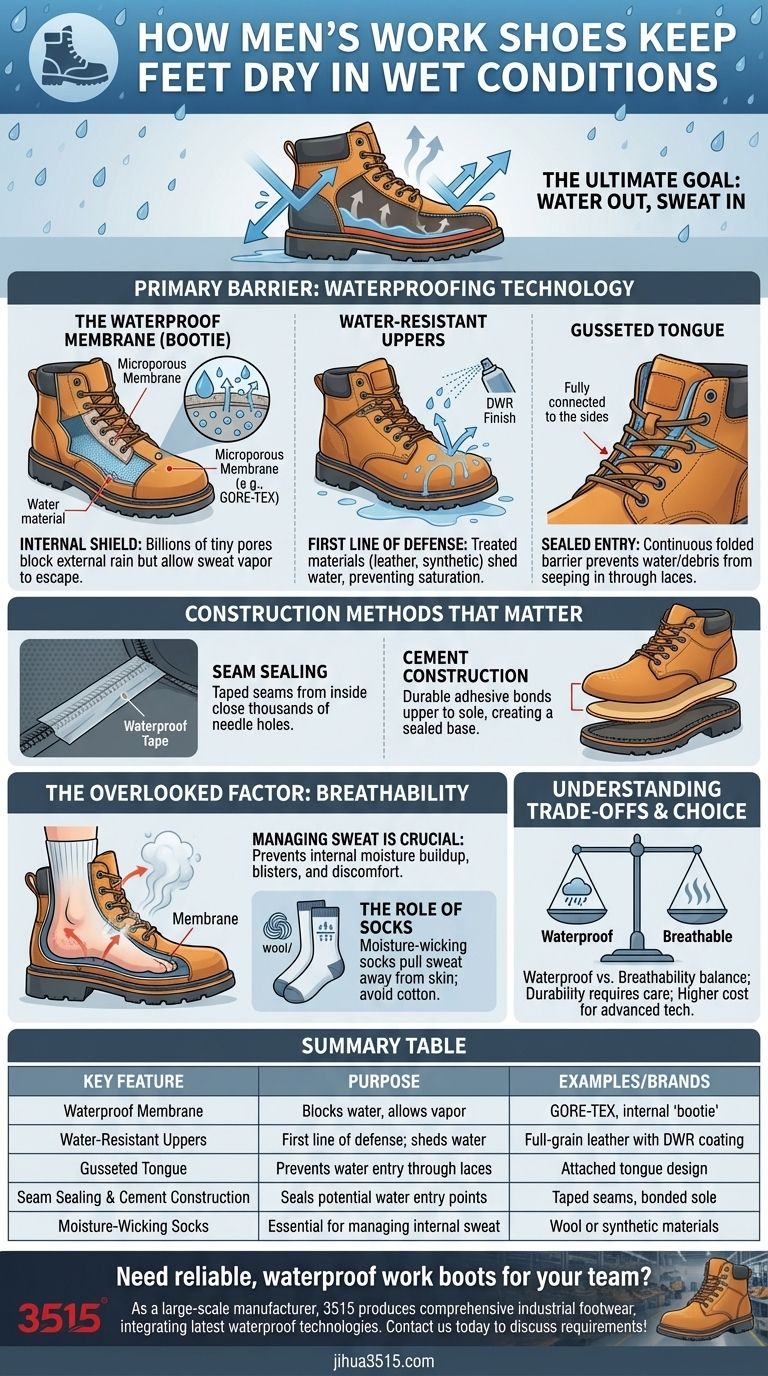

The Primary Barrier: Waterproofing Technology

True waterproof performance begins inside the shoe, with specialized layers and design features that create an impenetrable barrier against water.

The Waterproof Membrane (The "Bootie")

The core of modern waterproof footwear is a microporous membrane, often designed as a sock-like "bootie" that sits between the shoe's outer material and the inner lining.

Brands like GORE-TEX are famous for this technology. The membrane contains billions of pores per square inch that are thousands of times smaller than a water droplet but larger than a water vapor molecule. This clever design physically blocks rain and puddles from entering while allowing sweat to escape as vapor.

Water-Resistant Uppers

The outer material of the boot, whether it's full-grain leather, nubuck, or a synthetic fabric, serves as the first line of defense.

These materials are typically treated with a Durable Water Repellent (DWR) finish that causes water to bead up and roll off the surface. While not truly waterproof on its own, a well-treated upper prevents the boot from becoming saturated and heavy.

The Gusseted Tongue

A gusseted tongue is a critical and often overlooked feature. It is attached to the upper along the sides, not just at the bottom.

This creates a continuous, folded barrier that prevents water, mud, and debris from seeping into the boot through the eyelets and gaps around the tongue.

Construction Methods That Matter

How a shoe is assembled is just as important as the materials used. The seams and the point where the upper meets the sole are potential weak spots for water entry.

Seam Sealing

The process of stitching materials together creates thousands of tiny holes that water can penetrate. In high-quality waterproof footwear, these seams are sealed from the inside with a special waterproof tape, effectively closing these entry points.

Cement Construction

This method involves applying a strong adhesive to bond the upper directly to the sole. A proper cement construction creates a highly water-resistant, durable seal around the entire base of the foot, leaving no gaps for moisture to intrude.

The Overlooked Factor: Breathability

A boot that only blocks water without managing sweat will leave your feet feeling clammy and wet from the inside. This is where breathability becomes essential.

Why Sweat Management is Crucial

The average foot can produce a significant amount of sweat during a workday. If this moisture is trapped, it leads to discomfort, blisters, and an environment ripe for fungal growth.

True "dryness" means managing both external and internal moisture sources.

How Breathable Membranes Work

This is the second function of a microporous membrane like GORE-TEX. While its pores are too small for water droplets to enter, they are large enough for sweat vapor to pass through and escape from the boot.

The Role of Your Socks

The system is only as good as its weakest link. Wearing cotton socks will defeat the purpose of a breathable boot, as cotton absorbs and holds moisture next to your skin.

Moisture-wicking socks made from wool or synthetic materials are crucial. They pull sweat away from your skin and help the boot's membrane transport it out.

Understanding the Trade-offs

No single feature is perfect for every situation. It's important to understand the balance between different performance aspects.

Waterproofing vs. Breathability

There is always a trade-off between these two features. The most waterproof boots (like rubber boots) offer the least breathability. Conversely, the most breathable shoes are the least protective against water. Modern membranes aim to find the optimal balance for all-day comfort.

Durability and Maintenance

Waterproof features require care. DWR coatings on the upper will wear off over time and need to be reapplied with a spray-on or wash-in treatment. The internal membrane can also be punctured or damaged, compromising its effectiveness.

Cost

Technologies like GORE-TEX and high-quality sealed construction add complexity and cost to the manufacturing process. You should expect to invest more in a shoe that offers reliable, breathable waterproof performance.

Making the Right Choice for Your Goal

Select your footwear based on the specific conditions you face most often.

- If your primary focus is working in standing water or heavy rain: Prioritize a boot with a certified waterproof membrane (like GORE-TEX), seam sealing, and a high gusseted tongue.

- If your primary focus is working in hot, humid conditions with occasional water exposure: Look for a boot that balances waterproofing with high breathability, often found in models with synthetic or fabric uppers combined with a membrane.

- If your primary focus is light moisture like damp ground or occasional splashes: A boot with a well-treated leather upper and a sealed, cement-style construction may provide sufficient protection.

Understanding how these features work together empowers you to select work footwear that keeps you safe, dry, and productive in any condition.

Summary Table:

| Key Feature | Purpose | Examples/Brands |

|---|---|---|

| Waterproof Membrane | Blocks external water, allows sweat vapor to escape | GORE-TEX, internal 'bootie' |

| Water-Resistant Uppers | First line of defense; sheds water | Full-grain leather with DWR coating |

| Gusseted Tongue | Prevents water entry through laces | Attached tongue design |

| Seam Sealing & Cement Construction | Seals potential water entry points | Taped seams, bonded sole |

| Moisture-Wicking Socks | Essential for managing internal sweat | Wool or synthetic materials |

Need reliable, waterproof work boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof and breathable shoes and boots, integrating the latest technologies like sealed seams and advanced membranes for maximum protection and comfort.

We can help you equip your workforce with durable, high-performance footwear tailored to specific wet or humid conditions. Contact us today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do slip-resistant safety shoes prevent accidents in hotel catering? Mastering Kitchen Safety & Traction

- What is the importance of investing in premium non-slip shoes? Secure Your Safety and Comfort

- How does the floor type affect slip-resistant shoe choice? Match Your Sole to Your Surface

- What are the main components of a slip-resistant shoe? Unpacking the Anatomy of Workplace Safety

- What are the features of slip-resistant work boots? Key Elements for Ultimate Traction

- What does a soft toe provide? Lightweight Comfort for Low-Risk Work Environments

- What is the GRIP rating scheme for slip-resistant footwear? A Clear Guide to Workplace Safety

- What are the key features that differentiate non-slip shoes from regular shoes? Essential Safety for Your Workforce