Excellent traction in military boots is not the result of a single feature, but an engineered system. It is achieved through the specific combination of the outsole's rubber composition, the depth and pattern of its lugs, and a distinct heel design built for control and braking on unstable terrain.

The fundamental goal of a high-traction outsole is to create a stable, high-friction interface with the ground. This is done by using deep, multi-directional lugs to bite into soft surfaces while simultaneously channeling away water and debris to maintain contact.

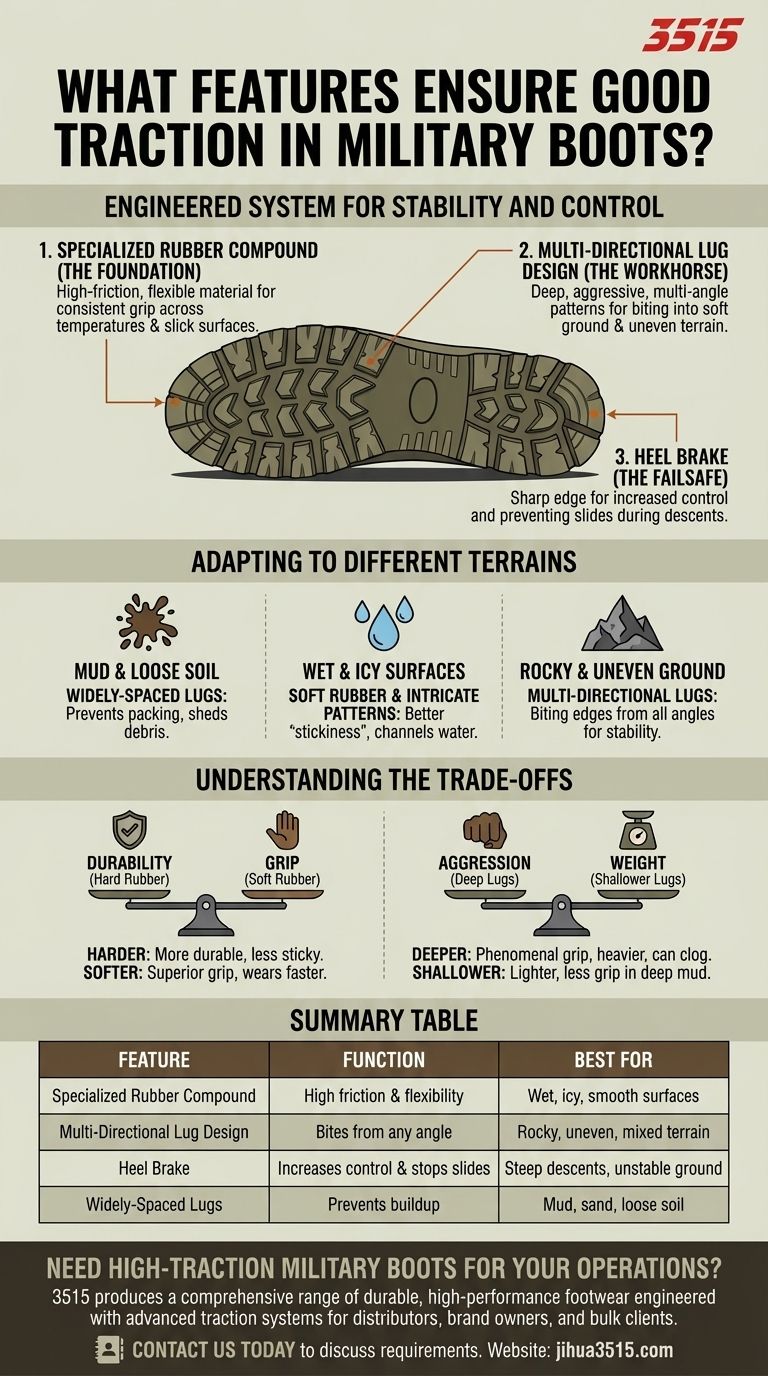

The Anatomy of a High-Traction Outsole

To truly understand traction, you must look at the outsole as three distinct components working in unison. The failure of any one component compromises the entire system's effectiveness.

The Foundation: Outsole Material

The vast majority of high-performance boot outsoles are made from specialized rubber compounds.

Rubber is the ideal material because it provides a high coefficient of friction while remaining flexible across a wide range of temperatures, ensuring a consistent grip on slick surfaces like wet rock or ice.

The Workhorse: Lug Design

Lugs are the deep, geometric patterns—the "tread"—on the bottom of the boot. Their design is the single most critical factor for traction on varied terrain.

Deep, aggressive lugs are designed to dig into soft or loose surfaces like mud, sand, or snow. The depth creates a physical anchor, preventing the foot from sliding.

Multi-directional patterns are crucial for maintaining grip on uneven or rocky ground. They ensure that no matter the angle of your foot, some part of the lug pattern is positioned to provide a biting edge and resist slipping.

Think of the difference between a slick racing tire (maximum surface contact on a clean track) and a heavy-duty off-road tire (deep voids to grip and shed mud). Military boot outsoles are the off-road tires.

The Failsafe: The Heel Brake

The heel area of the outsole is often distinct from the rest of the sole. It features a sharp, defined edge known as a heel brake.

This feature is designed specifically to increase friction and control during descents. As you walk downhill, the heel brake digs into the ground, acting as a stopping point to prevent uncontrolled slides.

How Traction Adapts to Different Terrains

An effective outsole pattern is not a one-size-fits-all solution. The design must account for the specific challenges posed by different environments.

For Mud and Loose Soil

The key here is widely-spaced lugs. If the lugs are too close together, mud and debris will pack into the voids, effectively turning the complex tread into a single, flat, and slippery surface.

For Wet or Icy Surfaces

On hard, wet surfaces, traction relies more on the rubber compound itself. Softer rubber provides a stickier grip. Additionally, smaller, intricate patterns can help channel water away from the contact point, preventing hydroplaning.

For Rocky and Uneven Ground

This is where multi-directional lugs are essential. As you traverse a rocky hillside, your foot lands at unpredictable angles. A pattern that can provide a biting edge from the front, side, and back ensures stability with every step.

Understanding the Trade-offs

There is no single "perfect" outsole. Every design choice involves a trade-off between competing priorities, and understanding these is key to selecting the right boot.

Durability vs. Grip

Softer rubber compounds provide superior grip, especially on smooth, wet surfaces. However, they wear down much faster than harder rubber compounds.

Harder rubber is extremely durable but offers less "stickiness," which can be a liability on slick rock or ice. Most manufacturers, like Vibram, create compounds that seek a balance between these two extremes.

Aggression vs. Weight

Extremely deep and aggressive lugs offer phenomenal grip in mud and snow. The trade-off is that they are heavier and can feel clumsy on flat, hard surfaces. They can also become clogged with thick clay, adding significant weight to each boot.

Making the Right Choice for Your Mission

Your choice should be dictated by the terrain you will most frequently encounter. Assess the outsole with a critical eye for its intended purpose.

- If your primary focus is all-terrain versatility: Look for a boot with medium-depth, multi-directional lugs and a well-defined heel brake.

- If your primary focus is wet or urban environments: Prioritize a boot with a slightly softer rubber compound and a pattern that has many smaller edges for gripping flat surfaces.

- If your primary focus is mud, snow, or loose earth: Seek out deep, aggressive, and widely-spaced lugs designed to dig in and shed debris effectively.

By understanding these core principles, you can look past marketing and assess a boot's true capability to keep you stable when it matters most.

Summary Table:

| Feature | Function | Best For |

|---|---|---|

| Specialized Rubber Compound | Provides high friction & flexibility | Wet, icy, or smooth surfaces |

| Multi-Directional Lug Design | Bites into ground from any angle | Rocky, uneven, or mixed terrain |

| Heel Brake | Increases control & prevents sliding | Steep descents and unstable ground |

| Widely-Spaced Lugs | Prevents mud/debris buildup | Mud, sand, or loose soil environments |

Need high-traction military boots for your operations?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-performance footwear tailored for distributors, brand owners, and bulk clients. Our production capabilities include all types of military boots and tactical footwear, engineered with advanced traction systems to meet the demands of any mission.

Contact us today to discuss your specific requirements and discover how our footwear solutions can enhance safety and performance for your team.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- How should excess dirt be removed from military boots? A Step-by-Step Guide to Proper Care

- What are some tips and warnings for cleaning suede military boots? Preserve Your Gear with a Gentle Touch

- Why should polish not be applied to combat boots? It Damages Breathability and Performance

- How long do combat boots typically last with proper care? Maximize Durability from 1 to 5+ Years

- What are jungle boots designed for? Surviving Hot, Wet, and Humid Environments

- What activities are combat boots suitable for? A Guide to Rugged Footwear for Demanding Use

- What features does the responsive insole in modern jungle boots provide? Dynamic Comfort for Long Treks

- How do the heights of combat boots and jump boots differ? A Guide to Purpose-Built Footwear