Choosing the right work boot requires a methodical approach that goes beyond brand or style. You must first analyze your specific job requirements and worksite conditions, then match them to the boot's protective features, support structure, and, most importantly, its fit.

The best work boot is not the one with the most features, but the one whose system of protection, support, and fit is perfectly aligned with the daily demands and hazards of your specific job.

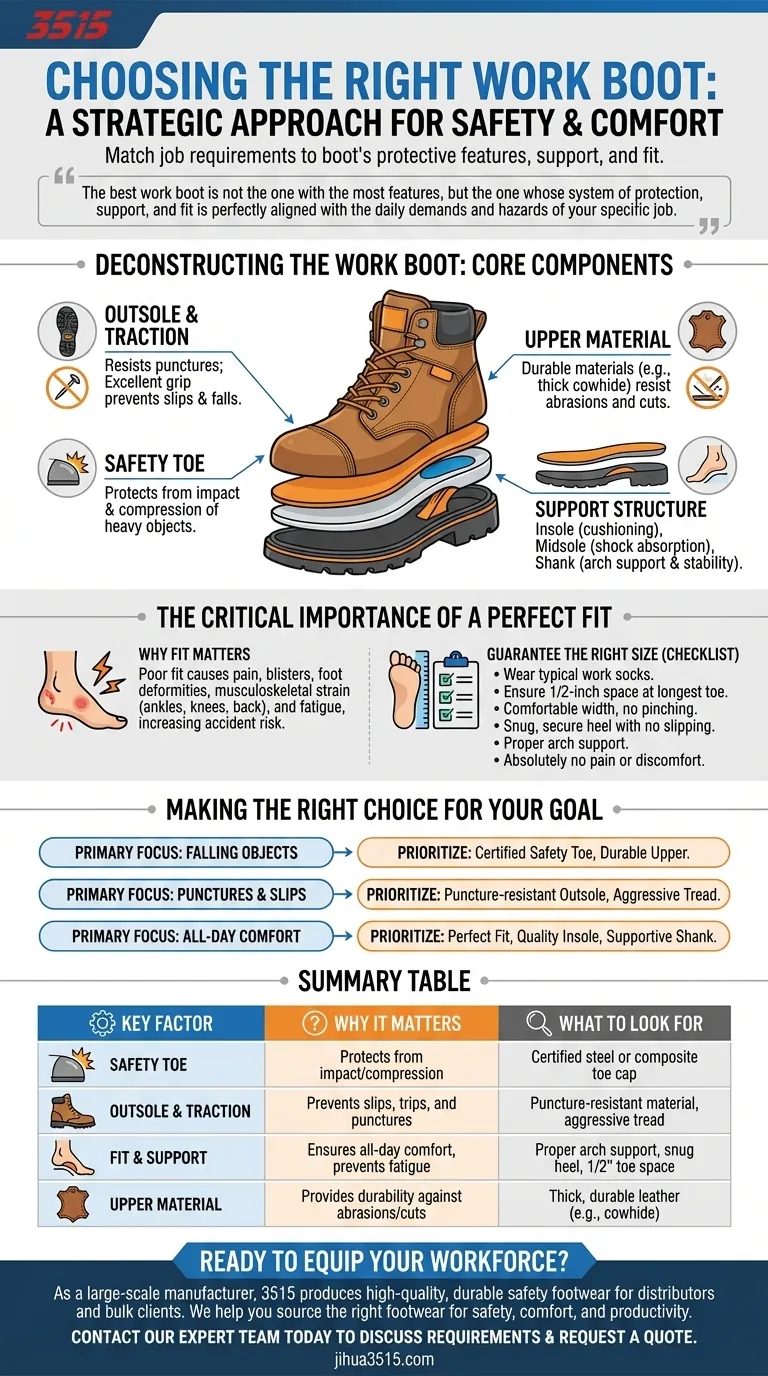

Deconstructing the Work Boot: Core Components

Understanding the anatomy of a work boot is the first step in making an informed decision. Each component serves a critical function for either safety, support, or durability.

The Foundation: Outsole and Traction

The outsole is your direct contact with the ground. It must be thick enough to resist punctures from sharp objects like nails while remaining lightweight enough for all-day wear.

Excellent traction is non-negotiable. The tread pattern and material determine your grip on various surfaces, preventing slips and falls.

Essential Protection: The Safety Toe

The most recognized feature of a work boot is its protective toe cap. Steel-toed boots are the standard for protecting feet from the impact and compression of heavy or falling objects.

The Support Structure

A boot's long-term comfort and support come from a system of internal components. The insole provides cushioning, the midsole absorbs shock, and a rigid shank provides crucial arch support and stability.

The Upper: Durability and Materials

The upper part of the boot is typically made from durable materials like thick cowhide. This provides a tough, resilient barrier against abrasions, cuts, and demanding work conditions.

The Critical Importance of a Perfect Fit

Even the most technologically advanced boot is ineffective and unsafe if it doesn't fit properly. An improper fit can lead to immediate discomfort and long-term health issues.

Why Fit Determines Safety and Comfort

Ill-fitting boots are a direct cause of blisters, pain (such as cuboid and lateral malleolus pain), and even foot deformities over time. This discomfort leads to fatigue and distraction, which can increase the risk of accidents.

A poor fit also creates musculoskeletal strain that can affect your ankles, knees, and back, impacting both your safety and overall well-being.

How to Guarantee the Right Size

Use this checklist when trying on any pair of work boots to ensure a precise fit:

- Wear your typical work socks during the fitting.

- Ensure there is about a half-inch of space between your longest toe and the front of the boot.

- The width should be comfortable, with no pinching on the sides of your foot.

- Your heel should feel snug and secure, with no significant slipping as you walk.

- Confirm the boot provides proper arch support for your foot type.

- Walk around and ensure there is absolutely no pain or major discomfort.

Making the Right Choice for Your Goal

Select your boot by prioritizing the features that address the biggest risks and demands of your workday.

- If your primary focus is protection from falling objects: Prioritize a certified safety toe and ensure the upper is made from thick, durable materials.

- If your primary focus is preventing punctures and slips: Scrutinize the outsole for puncture-resistant construction and an aggressive tread pattern for reliable traction.

- If your primary focus is all-day comfort and preventing fatigue: Pay meticulous attention to the fit, the quality of the insole, and the presence of a supportive shank.

Ultimately, choosing the right work boot is a direct investment in your own safety and long-term health on the job.

Summary Table:

| Key Factor | Why It Matters | What to Look For |

|---|---|---|

| Safety Toe | Protects feet from impact/compression | Certified steel or composite toe cap |

| Outsole & Traction | Prevents slips, trips, and punctures | Puncture-resistant material, aggressive tread |

| Fit & Support | Ensures all-day comfort, prevents fatigue | Proper arch support, snug heel, 1/2" toe space |

| Upper Material | Provides durability against abrasions/cuts | Thick, durable leather (e.g., cowhide) |

Ready to equip your workforce with the perfect work boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality, durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific demands and hazards of any job site.

We can help you source the right footwear to keep your team safe, comfortable, and productive.

Contact our expert team today to discuss your requirements and request a quote.

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the essential features all work boots should have regardless of gender? Non-Negotiable Safety & Support