To put it simply, a combination of intense heat, moisture, and caustic chemicals are the primary environmental conditions that damage firefighter boots. These elements work together to bake, dry out, and chemically attack the boot's materials, leading to premature failure.

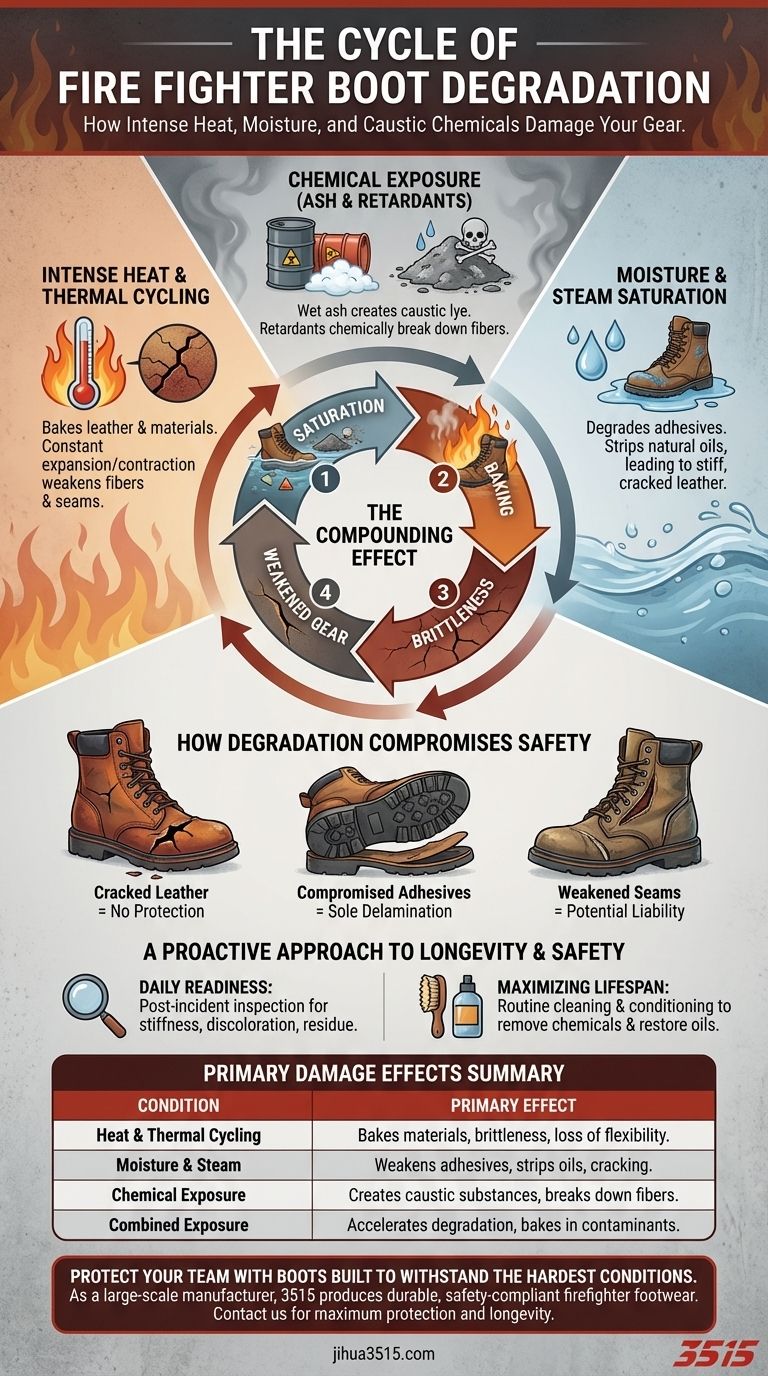

The core issue isn't a single event, but the cumulative effect of a harsh cycle. Firefighting exposes boots to intense heat, followed by saturation from water and chemicals, which then get "baked" into the material, compromising its structural integrity from the inside out.

The Primary Culprits of Boot Degradation

Understanding how each environmental factor attacks your boots is the first step toward mitigating damage and ensuring your gear remains safe and effective.

Intense Heat and Thermal Cycling

The most obvious threat is extreme heat. This direct thermal exposure bakes the leather and other materials, causing them to become brittle and lose their natural flexibility and strength.

This damage is compounded by thermal cycling—the rapid transition from extreme heat at a fire scene to ambient temperatures. This constant expansion and contraction weakens material fibers and seams over time.

Moisture and Steam Saturation

Water and steam are constant companions on the fireground. While boots are designed to be water-resistant, prolonged saturation can degrade the adhesives that bond the sole and other components.

Furthermore, when water soaks into leather and is then rapidly dried by ambient heat, it strips away the material's natural oils. This process leaves the leather stiff, prone to cracking, and vulnerable to physical damage.

Chemical Exposure from Ash and Retardants

This is one of the most insidious forms of damage. When ash becomes wet, it creates lye, a highly caustic and alkaline substance that chemically attacks and breaks down the fibers in leather.

Similarly, many fire retardants and foams contain caustic chemicals. If not properly cleaned off, these residues will continue to degrade the boot's material long after the fire is out.

The Compounding Effect of Combined Exposure

The true danger lies in how these factors interact. No single element works in isolation; their combined effect creates a vicious cycle of degradation that drastically shortens a boot's service life.

The Cycle of Baking and Brittleness

During a fire, boots are saturated with water, steam, wet ash, and chemical retardants. After the incident, the residual heat bakes these substances deep into the boot's materials.

This process accelerates the breakdown of the boot's structure far more than any single factor could alone. It effectively turns your boots into a brittle shell, compromising safety and support.

How Degradation Compromises Safety

This isn't just a matter of appearance. Brittle, cracked leather can no longer provide adequate protection from punctures or heat. Weakened seams can split open, and compromised adhesives can lead to sole delamination.

Ultimately, environmental damage directly impacts the boot's ability to protect you, turning a critical piece of personal protective equipment into a potential liability.

A Proactive Approach to Longevity and Safety

Proper inspection and maintenance are not optional; they are critical safety functions. By understanding the threats, you can take direct action to counter them.

- If your primary focus is daily readiness: Perform a thorough post-incident inspection, specifically looking for stiffness, discoloration, or any residue from ash and retardants.

- If your primary focus is maximizing lifespan: Implement a routine cleaning and conditioning protocol to remove caustic chemicals and restore essential oils to the leather after exposure.

Consistent care is the most effective defense against the harsh environment you work in.

Summary Table:

| Environmental Condition | Primary Damage Effect |

|---|---|

| Intense Heat & Thermal Cycling | Bakes materials, causing brittleness and loss of flexibility. |

| Moisture & Steam Saturation | Weakens adhesives, strips natural oils from leather, leading to cracking. |

| Chemical Exposure (Ash, Retardants) | Creates caustic substances that chemically break down boot fibers. |

| Combined Exposure (The Cycle) | Accelerates degradation by baking contaminants into the boot's structure. |

Protect Your Team with Boots Built to Withstand the Harshest Conditions

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and safety-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional boots, including advanced firefighter footwear engineered to resist the damaging cycle of heat, moisture, and chemicals.

We ensure your team has reliable gear that offers maximum protection and longevity. Contact us today to discuss your specific needs and explore our robust product lines.

Get a Quote & Discuss Your Requirements

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries