At its core, the ASTM F2413-18 certification is the baseline U.S. standard that guarantees safety footwear meets minimum performance requirements against specific workplace hazards. This standard mandates that all certified footwear must have a protective safety toe, and it also provides a framework for testing additional features like electrical hazard resistance, puncture resistance, and more.

Understanding ASTM F2413-18 is about recognizing that it's not a single, all-encompassing rating. Instead, it’s a foundational standard for the safety toe, with a series of specific codes for additional protections that a boot may or may not include.

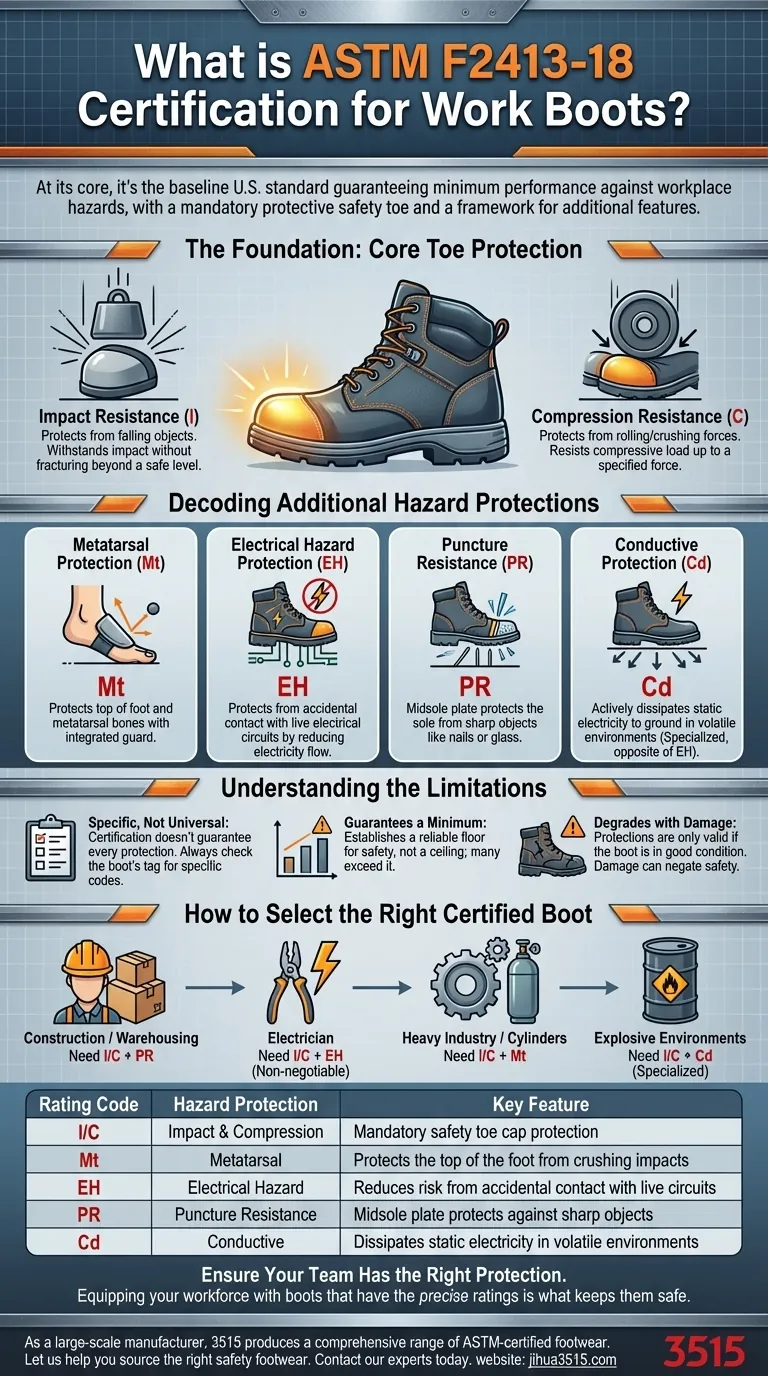

The Foundation: Core Toe Protection

All footwear that meets the ASTM F2413-18 standard must first pass two fundamental tests for the safety toe cap, whether it's made of steel, composite, or alloy material.

Impact Resistance (I)

This test evaluates the toe cap's ability to protect the foot from falling objects. A specific weight is dropped from a set height, and the toe cap must withstand the impact without fracturing or deforming beyond a safe clearance level.

Compression Resistance (C)

This test measures the toe cap's ability to protect the foot from rolling or crushing forces. A heavy, rolling object is applied to the toe, and the cap must resist the compressive load up to a specified force.

Decoding the Additional Hazard Protections

Beyond the mandatory toe protection, the standard outlines several additional performance criteria. A boot will only carry these ratings if it has been specifically tested and certified for them.

Metatarsal Protection (Mt)

This rating signifies protection for the top of the foot and the metatarsal bones. Footwear with this rating has an integrated guard that deflects impacts to this highly vulnerable area.

Electrical Hazard Protection (EH)

EH-rated boots are designed to protect the wearer from accidental contact with live electrical circuits. The outsole is constructed to significantly reduce the flow of electricity through the boot and to the ground.

Puncture Resistance (PR)

This rating indicates that the boot has a puncture-resistant plate built into the midsole. This plate is designed to protect the sole of the foot from sharp objects like nails, glass, or scrap metal.

Conductive Protection (Cd)

Conductive footwear is highly specialized and designed to do the opposite of EH boots. It actively dissipates static electricity from the body into the ground, reducing the risk of static spark in volatile or explosive environments.

Understanding the Limitations

True expertise comes from knowing what a standard does and does not guarantee. Being aware of these points is crucial for proper safety planning.

Certification is Specific, Not Universal

A boot certified to ASTM F2413-18 does not automatically have every protection. A boot can be rated for Impact (I) and Compression (C) but have no EH or PR rating. Always check the boot’s tag for the specific codes relevant to your work.

The Standard Guarantees a Minimum

The certification ensures a boot meets a baseline performance level. While many manufacturers may exceed these minimums, the standard's purpose is to establish a reliable floor for safety, not a ceiling.

Protection Degrades with Damage

A boot's certified protections are only valid if the boot is in good condition. A cracked toe cap, a deep cut in the sole, or excessive wear can compromise or entirely negate its safety features.

How to Select the Right Certified Boot

Choosing the correct footwear means matching the boot's specific ASTM ratings to the known hazards of your environment.

- If your primary focus is construction or warehousing: You require boots with Impact (I), Compression (C), and likely Puncture Resistance (PR) to guard against falling materials and sharp ground debris.

- If your primary focus is working as an electrician: An Electrical Hazard (EH) rating is non-negotiable to protect against shock, in addition to the core I/C toe protection.

- If your primary focus is heavy industry or handling large cylinders: Prioritize Metatarsal (Mt) protection to shield the top of your foot from crushing injuries.

- If your primary focus is environments with explosive materials: You must look for the specialized Conductive (Cd) rating to safely manage static discharge.

By understanding these codes, you can move beyond simple compliance and choose footwear that provides the precise protection you need for your specific work environment.

Summary Table:

| Rating Code | Hazard Protection | Key Feature |

|---|---|---|

| I/C | Impact & Compression | Mandatory safety toe cap protection |

| Mt | Metatarsal | Protects the top of the foot from crushing impacts |

| EH | Electrical Hazard | Reduces risk from accidental contact with live circuits |

| PR | Puncture Resistance | Midsole plate protects against sharp objects |

| Cd | Conductive | Dissipates static electricity in volatile environments |

Ensure Your Team Has the Right Protection

Understanding the ASTM F2413-18 standard is the first step. Equipping your workforce with boots that have the precise ratings for their job hazards is what keeps them safe and productive.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the exact combination of safety features—from I/C and PR to EH and Mt—that your specific work environment demands.

Let us help you source the right safety footwear. Contact our experts today to discuss your requirements and benefit from our high-volume manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management