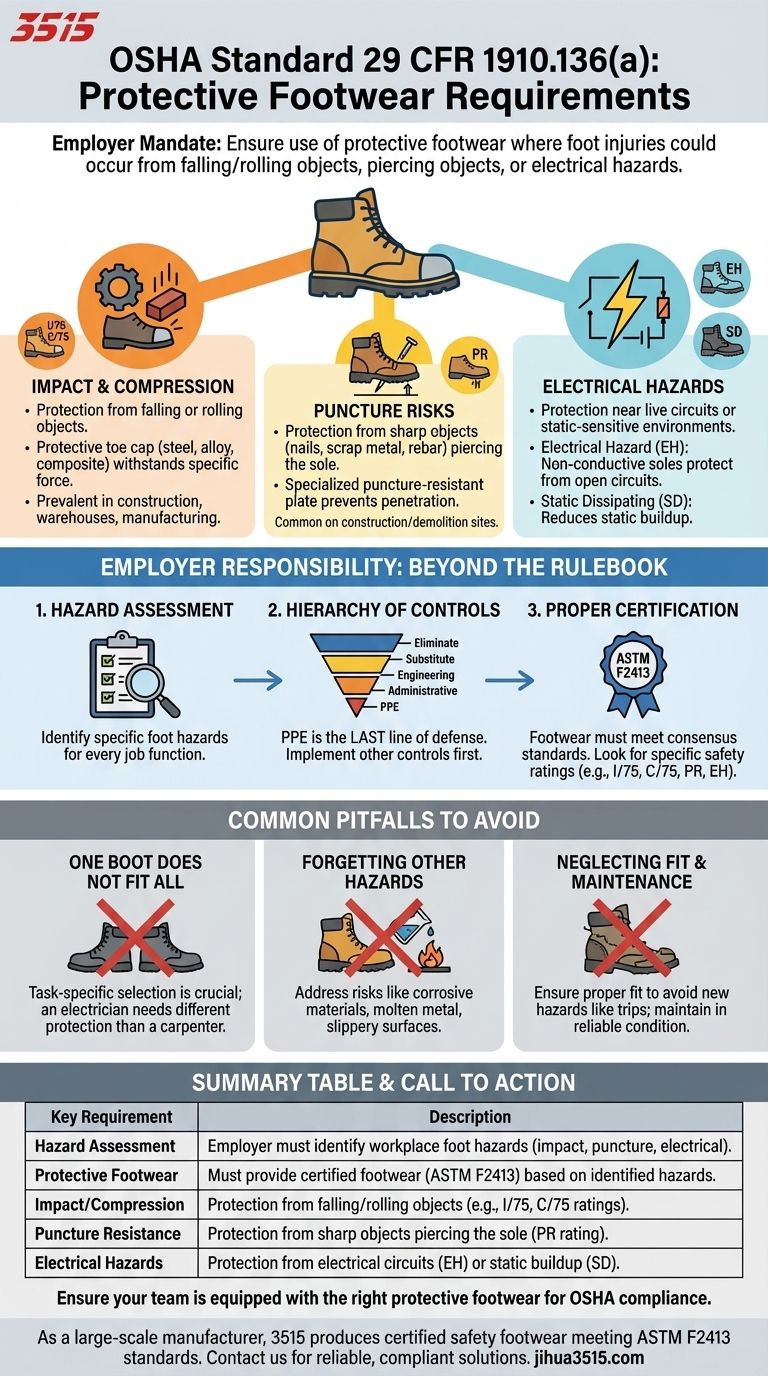

OSHA standard 29 CFR 1910.136(a) mandates that employers must ensure their employees use protective footwear when working in areas where foot injuries could occur. This requirement is specifically triggered by the presence of falling or rolling objects, objects that could pierce the sole of the shoe, and recognized electrical hazards.

The core principle of this standard is not simply about providing boots, but about an employer's fundamental responsibility to first conduct a thorough hazard assessment and then select footwear specifically designed to protect against the identified risks.

The Three Core Hazard Categories in Detail

The OSHA standard is built around mitigating three primary categories of foot hazards. Understanding each one is critical for proper compliance and, more importantly, for ensuring genuine worker safety.

Protection from Impact and Compression

This refers to dangers from falling or rolling objects. It is the most commonly recognized need for safety footwear, often associated with a "steel toe."

These hazards are prevalent in environments like construction sites, warehouses, and manufacturing plants where heavy materials, equipment, or parts are handled. The protective toe cap, made of steel, alloy, or composite material, is designed to withstand a specific force of impact and compression.

Protection from Puncture Risks

This category addresses the danger of sharp objects piercing the sole of a shoe and injuring the foot from below.

Common culprits include nails, screws, scrap metal, and rebar found on construction, demolition, or renovation sites. Puncture-resistant footwear has a specialized plate positioned within the sole to prevent penetration by these objects.

Protection from Electrical Hazards

This is a more specialized but critical requirement for anyone working near live electrical circuits or in environments sensitive to static electricity.

Protective footwear in this category can serve two different functions. Electrical Hazard (EH) rated boots are designed with non-conductive soles to protect the wearer from open circuits. Conversely, Static Dissipating (SD) footwear is designed to reduce the buildup of static electricity, protecting sensitive equipment or preventing ignition in flammable environments.

The Employer's Responsibility: Beyond the Rulebook

True compliance with OSHA 1910.136(a) goes far beyond simply buying a case of safety boots. It is a systematic process rooted in the broader requirements for all Personal Protective Equipment (PPE).

It Starts with a Hazard Assessment

The foundation of any PPE program is a formal, documented hazard assessment, as required by OSHA standard 1910.132(d). Employers must walk through the workplace, identify potential foot hazards, and determine the type of protection needed.

This assessment dictates the specific features required, whether it's an impact-rated toe, a puncture-resistant sole, an EH rating, or a combination of protections.

Hierarchy of Controls

Protective footwear is considered PPE, which is the last line of defense against injury. Before relying on boots, employers are expected to implement other controls to eliminate or reduce the hazard.

For example, implementing safer material handling procedures to prevent objects from falling is an engineering control that is more effective than simply requiring impact-resistant boots after a failure. Footwear is for the hazards that remain after these other measures are in place.

Ensuring Proper Certification

Simply providing a sturdy work boot is not enough. The footwear selected must meet or exceed specific consensus standards, such as those from ASTM International.

The current standard is ASTM F2413. Any footwear claiming to be protective must be marked with its specific safety rating (e.g., I/75 for impact, C/75 for compression, PR for puncture resistance), proving it has been tested for those hazards.

Common Pitfalls to Avoid

Navigating PPE requirements can be complex, and several common mistakes can lead to non-compliance and worker injury.

One Boot Does Not Fit All

A frequent error is issuing a single type of safety boot to all employees, regardless of their specific job tasks. An electrician needs EH-rated boots, while a carpenter on a framing crew needs puncture resistance. The hazard assessment must inform a task-specific selection.

Forgetting About Other Hazards

While 1910.136(a) focuses on impact, puncture, and electrical risks, the employer's general duty is to protect against all recognized hazards. This can include risks from corrosive materials, molten metal splashes, or extremely hot or slippery surfaces, all of which may require specialized footwear.

Neglecting Fit and Maintenance

Compliance doesn't end when the boots are distributed. The employer must ensure the footwear fits each employee properly. Poorly fitting shoes can create new hazards, like trips and falls. Furthermore, the footwear must be maintained in a sanitary and reliable condition.

How to Apply This to Your Project

Your approach to protective footwear should be guided by the specific risks inherent in your work environment.

- If your primary focus is compliance as an employer: Begin with a formal, written hazard assessment for every job function to identify specific foot dangers and dictate your selection criteria.

- If your primary focus is safety on a construction or demolition site: Prioritize footwear with certified impact and compression ratings (I/75, C/75) and, crucially, a puncture-resistant (PR) sole.

- If your primary focus is working near electrical equipment: Ensure your team is equipped with non-conductive Electrical Hazard (EH) rated boots that are in good condition, free from embedded conductive materials.

Ultimately, effective foot protection is achieved not by a rule, but by a continuous process of hazard assessment, control, and providing the correct equipment for the task.

Summary Table:

| Key Requirement | Description |

|---|---|

| Hazard Assessment | Employer must identify workplace foot hazards (impact, puncture, electrical). |

| Protective Footwear | Must provide certified footwear (ASTM F2413) based on identified hazards. |

| Impact/Compression | Protection from falling/rolling objects (e.g., I/75, C/75 ratings). |

| Puncture Resistance | Protection from sharp objects piercing the sole (PR rating). |

| Electrical Hazards | Protection from electrical circuits (EH rating) or static buildup (SD rating). |

Ensure your team is equipped with the right protective footwear for OSHA compliance.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial shoes and boots, including those meeting ASTM F2413 standards for impact, compression, puncture, and electrical hazards.

Let us help you protect your workforce with reliable, compliant footwear. Contact our team today for a consultation to discuss your specific needs and volume requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

People Also Ask

- What materials should a good safety shoe include? The Ultimate Guide to Protective Footwear

- What factors should be considered when choosing between steel-toe and soft-toe boots? Ensure Safety and Comfort

- What are the core advantages of using impact-resistant safety shoes in dairy farm mechanical work zones?

- What materials are typically used in safety trainers? A Guide to Protective Footwear Components

- How does comfort factor into selecting work shoes? Ensure Safety and Reduce Fatigue

- Why is a server equipped with a high-performance GPU necessary for safety shoe violation detection systems? Ensure Real-time Accuracy & Safety

- What are the benefits of using waterproof safety shoes during mining road maintenance and dust suppression activities?

- What is the role of a Cycle Ergometer when testing high-altitude safety shoes or training shoes? Maximize Performance