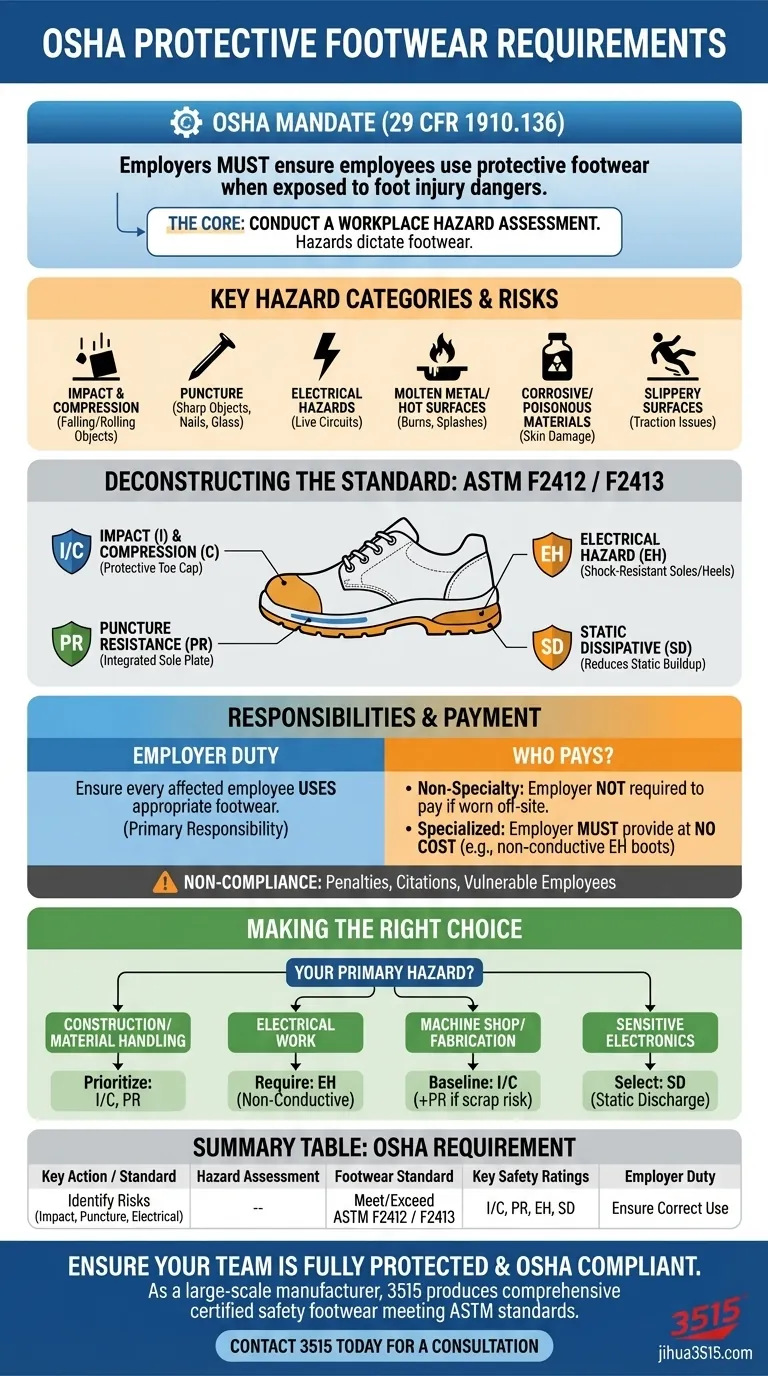

At its core, OSHA requires employers to ensure employees use protective footwear when their work exposes them to any danger of foot injury. This includes risks from falling or rolling objects, items that could pierce the sole, and electrical hazards. To be compliant, this footwear must meet or be equivalent to the technical specifications outlined in recognized consensus standards, such as those from ASTM International.

The fundamental requirement is not simply to provide safety shoes, but to first conduct a workplace hazard assessment. The specific type of protective footwear required is dictated entirely by the specific dangers—impact, puncture, or electrical—identified in that assessment.

When Does OSHA Mandate Protective Footwear?

The OSHA standard for protective footwear, found in 29 CFR 1910.136, is triggered by the presence of specific workplace hazards. The employer is responsible for identifying these risks.

The Foundation: The Hazard Assessment

Before any footwear is selected, the employer must assess the workplace to determine if hazards that necessitate the use of protective footwear are present.

This assessment identifies the nature and extent of potential foot injuries, which then dictates the level of protection required.

Key Hazard Categories

OSHA guidelines highlight several common situations where protective footwear is necessary:

- Impact and Compression: Danger from falling or rolling objects, such as in construction, warehousing, or manufacturing.

- Puncture: Risk from sharp objects that could pierce the sole, like nails, scrap metal, or glass.

- Electrical Hazards: Environments where workers may be exposed to live circuits or conductors.

- Molten Metal or Hot Surfaces: Work in foundries or with hot asphalt where splashes or contact could cause severe burns.

- Corrosive or Poisonous Materials: Handling chemicals that could damage the skin.

- Slippery Surfaces: Situations where enhanced traction is critical to preventing falls.

- Static Discharge: Workplaces where static electricity could damage sensitive components or create a fire risk.

Deconstructing the "Protective" Standard

OSHA doesn't write the technical specifications for footwear itself. Instead, it defers to consensus standards developed by expert organizations to ensure footwear is genuinely protective.

The Role of ASTM and ANSI

The primary standards referenced for safety footwear are ASTM F2412 and ASTM F2413 (which supersedes the older ANSI Z41 standard). A shoe that is OSHA compliant will be marked as meeting these standards.

What the Standards Certify

Footwear certified to these standards is tested for resistance against specific threats. The markings on the shoe's tongue label will indicate what it protects against.

- Impact (I) and Compression (C): The shoe has a protective toe cap that withstands a heavy falling object and being crushed under a heavy rolling object.

- Puncture Resistance (PR): The shoe has a plate integrated into the sole to prevent penetration by sharp objects from below.

- Electrical Hazard (EH): The shoe is made with non-conductive, electric-shock-resistant soles and heels, providing a secondary source of protection on dry surfaces.

- Static Dissipative (SD): The shoe is designed to reduce the buildup of static electricity by conducting it to the ground.

Understanding Employer and Employee Responsibilities

Compliance goes beyond simply having the right shoes on site. It involves a clear understanding of who is responsible for what.

The Mandate to Ensure Use

The employer's primary duty is to ensure that every affected employee uses the appropriate protective footwear for the hazards they face.

The Question of Payment

A common point of confusion is who pays for the footwear. According to OSHA, employers are not required to pay for non-specialty safety-toe footwear if they permit employees to wear it off the job site.

However, if the footwear is highly specialized and unsuitable for use outside of the workplace (e.g., non-conductive EH boots used only for specific tasks), the employer is required to provide it at no cost to the employee.

Consequences of Non-Compliance

Failure to adhere to OSHA's PPE regulations, including protective footwear, can result in significant penalties and citations during an inspection. More importantly, it leaves employees vulnerable to preventable injuries.

Making the Right Choice for Your Goal

The right footwear is always determined by the specific hazards of the job. Use your hazard assessment to guide your selection.

- If your primary focus is construction or material handling: Prioritize footwear with certified Impact (I), Compression (C), and Puncture Resistance (PR) ratings.

- If your primary focus is electrical work: You must require non-conductive footwear with an Electrical Hazard (EH) rating.

- If your primary focus is a machine shop or fabrication floor: A standard safety-toe shoe meeting basic impact and compression standards is the baseline, with puncture resistance added if scrap metal is a risk.

- If your primary focus is protecting sensitive electronics: Select footwear with a Static Dissipative (SD) rating to prevent static discharge.

Ultimately, compliant protective footwear is a critical component of a safety program built on a thorough understanding of your unique work environment.

Summary Table:

| OSHA Requirement | Key Action / Standard |

|---|---|

| Hazard Assessment | Employer must identify foot injury risks (impact, puncture, electrical). |

| Footwear Standard | Must meet or exceed ASTM F2412 / F2413 specifications. |

| Key Safety Ratings | I/C (Impact/Compression), PR (Puncture Res.), EH (Electrical Hazard). |

| Employer Duty | Ensure employees use correct footwear for identified hazards. |

Ensure Your Team is Fully Protected and OSHA Compliant

Navigating OSHA requirements and selecting the right protective footwear for your specific hazards can be complex. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective shoes designed to meet ASTM standards, ensuring your workforce is safe and your business is compliant.

Let us help you mitigate risk and protect your most valuable asset—your people.

Contact 3515 today for a consultation to find the perfect safety footwear solution for your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort