At its core, metatarsal protection (MT) in a work boot safeguards the delicate, bridge-like bones on the top of your foot. It is a specialized shield, distinct from a standard safety toe, designed to protect this vulnerable area from severe impact and compression injuries caused by falling or rolling objects.

While a safety toe protects the tips of your toes from being crushed, a metatarsal guard extends that protection up the foot, shielding the long bones that are completely exposed in a standard safety-toe boot.

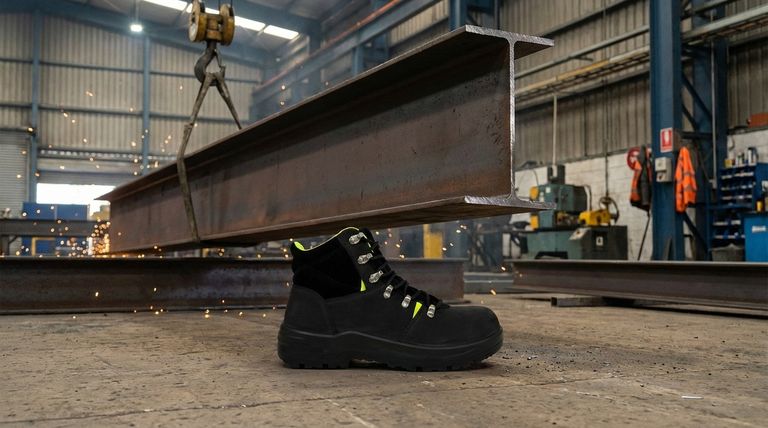

Beyond the Steel Toe: The Role of Metatarsal Guarding

To truly understand its importance, you must first recognize the limitations of a standard safety boot.

The Vulnerable Metatarsal Bones

The metatarsal bones are the five long bones that connect your toes to the back of your foot. They form the primary structure of your foot's arch and are crucial for balance and movement.

Unfortunately, these bones are highly susceptible to fracture from direct impact from above.

The Limits of a Standard Safety Toe

A standard safety toe cap, whether made of steel, composite, or alloy, is an essential feature. It is incredibly effective at preventing injuries from cutting hazards, punctures, and direct impacts to the very front of the foot.

However, the protective cap ends just behind the toes. This leaves the entire top of your foot exposed to any object that might fall or be dropped.

How Metatarsal Guards Provide Protection

Metatarsal guards are rigid shields designed to absorb and distribute the force of an impact across a wider area. This prevents the force from concentrating on a single bone and causing a fracture.

These guards are typically constructed in one of two ways:

- Internal Guards: A protective plate is built directly into the boot, sitting between your foot and the boot's upper material (like the tongue).

- External Guards: A protective element is attached to the outside of the boot, often covering the laces. This design is common in industries like welding to also deflect sparks and molten metal.

Key Hazards and Official Standards

Metatarsal protection is not a general-purpose feature; it is specified for environments with a clear and present danger to the top of the foot.

The Hazards It Addresses

This protection is engineered specifically for risks involving direct impact and compression. Think of a heavy tool slipping from your hands, a piece of building material falling from a height, or a heavy cart rolling over your foot.

These are common dangers in heavy industries, manufacturing, construction, and any environment where heavy materials are handled regularly.

The Official ASTM Label

Boots that meet the ASTM International standard for metatarsal protection are clearly marked.

Look for a tag on the boot that includes a black rectangle with the letter 'M'. This is the universal indicator that the boot is equipped with a certified metatarsal guard.

Common Pitfalls to Avoid

Understanding the distinction between different safety features is critical to ensuring you have the right level of personal protective equipment (PPE).

Misconception: All Safety Boots Are Equal

The most common mistake is assuming all safety boots offer the same protection. A standard safety toe boot does not include metatarsal protection.

MT protection is a specialized, additional feature. You must specifically look for boots with this rating if your workplace risk assessment demands it.

The Trade-off: Flexibility and Weight

The added protection of a metatarsal guard comes with a trade-off. The protective plate, whether internal or external, can make the boot feel stiffer and slightly heavier than a standard safety boot.

While modern designs have improved comfort and flexibility, it is a factor to consider when choosing your footwear.

Making the Right Choice for Your Goal

Selecting the proper boot depends entirely on a realistic assessment of your daily work environment.

- If your primary focus is general safety in a low-hazard environment: A standard safety-toe boot is likely sufficient to protect against occasional bumps and stubs.

- If your primary focus is working in construction, heavy manufacturing, or welding: Metatarsal protection is a non-negotiable safeguard against falling tools, materials, and sparks.

- If your primary focus is handling heavy, rolling objects like pipes or barrels: The added compression and impact resistance of an MT guard is essential for preventing severe crush injuries to the top of your foot.

Choosing the right level of protection begins with a clear understanding of the specific risks you face each day.

Summary Table:

| Protection Feature | What It Protects | Key Hazard Addressed |

|---|---|---|

| Standard Safety Toe | Tips of the toes | Crushing, punctures |

| Metatarsal (MT) Guard | Top of the foot (metatarsal bones) | Falling/rolling objects |

Ensure your workforce is fully protected. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear, including boots with ASTM-rated metatarsal protection for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed for heavy industry. Contact us today for durable, reliable footwear solutions tailored to your specific hazards.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What is the purpose of Chemical Resistant work boots? Ensure Total Foot Protection from Hazards

- What are the differences between mid-cut and high-cut synthetic/leather boots? Choose the Right Boot for Your Needs

- What type of socks are recommended for winter work boots? Stay Warm and Dry on the Job

- What features should one look for in wildland firefighter boots? Critical NFPA 1977 Safety Elements

- How should motorcycle boots be worn in relation to pants? A Guide to Safety and Function

- How does an electronic Metronome standardize muscle endurance testing? Master the Pace for Safety Boot Performance

- What are the unique characteristics of Western boots? The Practical Design Behind the Iconic Style

- What are the key ASTM standards for work boots? Your Guide to Certified Footwear Safety