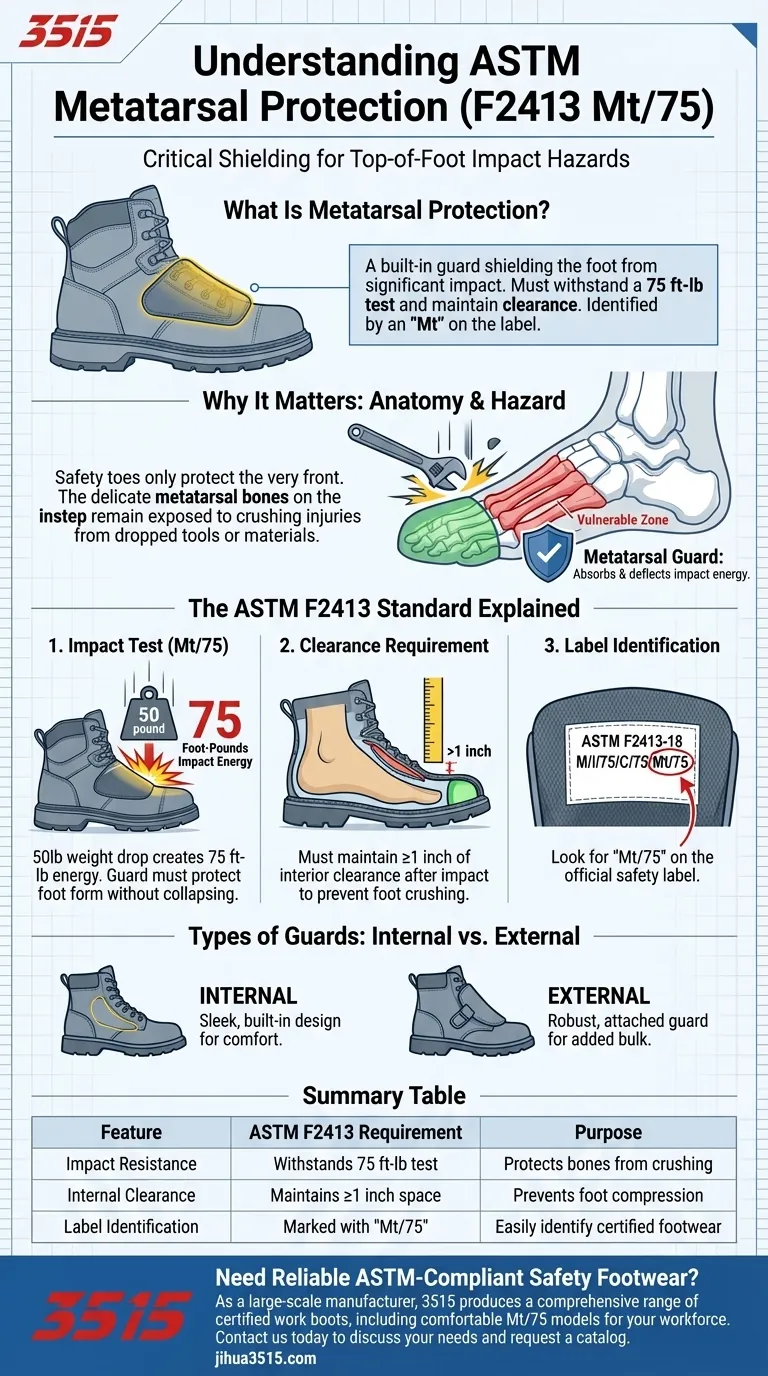

In short, metatarsal protection in ASTM-compliant footwear involves a built-in guard that shields the top of your foot from a significant impact. To meet the standard, a boot must withstand a 75 foot-pound impact test and maintain a minimum clearance inside, ensuring the foot is not crushed. Footwear that meets this specific requirement is clearly identified with an "Mt" on its official ASTM safety label.

The core purpose of the ASTM metatarsal standard is to provide critical protection for the delicate bones on top of your foot—an area left vulnerable by standard safety-toe caps alone.

What is Metatarsal Protection (And Why It Matters)

Beyond the Safety Toe

A standard safety toe cap, whether steel or composite, is designed to protect your toes from being crushed or severed by direct impact or compression.

However, these toe caps only cover the very front of the foot. The five long metatarsal bones, which connect your toes to the rest of your foot, remain exposed.

The Anatomy of the Hazard

The top of your foot, or instep, is a complex structure with little natural padding. A dropped tool, a falling piece of equipment, or a rolling object can easily fracture these bones.

Such injuries are debilitating, painful, and often lead to long recovery times. Metatarsal protection is specifically designed to prevent this exact type of accident.

The Role of a Metatarsal Guard

A metatarsal guard is essentially a shield that covers the instep area of the boot, extending from the back of the safety toe cap up toward the ankle.

This guard is engineered to absorb and deflect the energy from an impact, spreading the force over a wider area and preventing it from being concentrated on the fragile bones beneath.

The ASTM Standard (F2413) Explained

The specific standard governing this feature is ASTM F2413. When you see "Mt" on a boot's label, it signifies compliance with the following rigorous tests.

The Impact Test (Mt/75)

This is the primary performance requirement. A 50-pound weight is dropped onto the metatarsal guard from a specified height, creating an impact energy of 75 foot-pounds.

The test is a pass/fail. The guard must successfully protect the foot form from the impact without collapsing.

The Clearance Requirement

During the impact test, the guard is not allowed to deform to the point where it infringes on a safe interior clearance.

The standard requires at least one inch of clearance be maintained between the top of the foot form and the interior of the guard after the impact occurs. This ensures the foot is not crushed even if the guard is dented.

Identifying Compliant Footwear: The 'Mt' Label

The only way to be certain your footwear provides certified metatarsal protection is to check the label, which is typically sewn onto the tongue.

A compliant label will read something like: ASTM F2413-18 M/I/75/C/75/Mt/75. The Mt/75 at the end is the specific designation for metatarsal protection meeting the 75 foot-pound impact test.

Understanding the Trade-offs

Comfort and Flexibility

Historically, metatarsal guards were often rigid and external, reducing the boot's flexibility.

Modern designs have improved significantly, with many boots featuring internal, hinged, and anatomically shaped guards made from advanced materials. However, a boot with an "Mt" rating will almost always be slightly stiffer and heavier than one without.

Internal vs. External Guards

You will encounter two primary designs for metatarsal guards.

Internal guards are built directly into the boot's construction, making for a sleeker look. External guards are attached to the outside of the boot, offering robust protection but adding bulk. The choice often comes down to the specific job hazard and personal preference.

Making the Right Choice for Your Goal

- If your primary focus is working in construction or a warehouse: Metatarsal protection is a crucial upgrade to guard against dropped tools, building materials, and heavy pallets.

- If your primary focus is welding, foundry work, or heavy manufacturing: The 'Mt' rating is non-negotiable for protecting your feet from heavy, falling industrial objects.

- If your primary focus is general light-duty work with no overhead drop hazards: A standard safety-toe boot (rated I/75 C/75) may be sufficient, but a thorough risk assessment of your environment is always the best practice.

Ultimately, choosing footwear with metatarsal protection is a critical decision based on understanding the specific risks you face each day.

Summary Table:

| Feature | ASTM F2413 Requirement | Purpose |

|---|---|---|

| Impact Resistance | Withstands a 75 ft-lb impact test | Protects metatarsal bones from crushing injuries |

| Internal Clearance | Maintains ≥1 inch of space after impact | Prevents foot compression even if the guard deforms |

| Label Identification | Marked with 'Mt/75' on the safety label | Easily identify certified protective footwear |

Need reliable ASTM-compliant safety footwear with metatarsal protection?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified work boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, including models with advanced, comfortable metatarsal guards designed to meet the rigorous ASTM F2413 Mt/75 standard.

We ensure your workforce is protected from top-of-foot hazards with durable, high-performance footwear. Contact us today to discuss your specific needs and request a catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What precautions should be taken when drying work boots? Avoid High Heat to Protect Your Investment

- What practical features made engineer boots popular with workers? The Ultimate Guide to Industrial Safety Footwear

- When and by whom were engineer boots first produced? Discover the Origins of an Industrial Icon

- What is the historical origin of moc toe boots? An American Industrial Legacy

- What are the key differences between traditional cowboy boots and Western-style work boots? Choosing the Right Boot for Your Needs

- Are Goodyear welted boots worth it? The Ultimate Guide to Lifelong Footwear

- What features should be considered when choosing work boots for women? Essential Guide for Safety & Comfort

- How did monkey boots influence the popularity of lace-to-toe designs? A Look at Subcultural Style Evolution