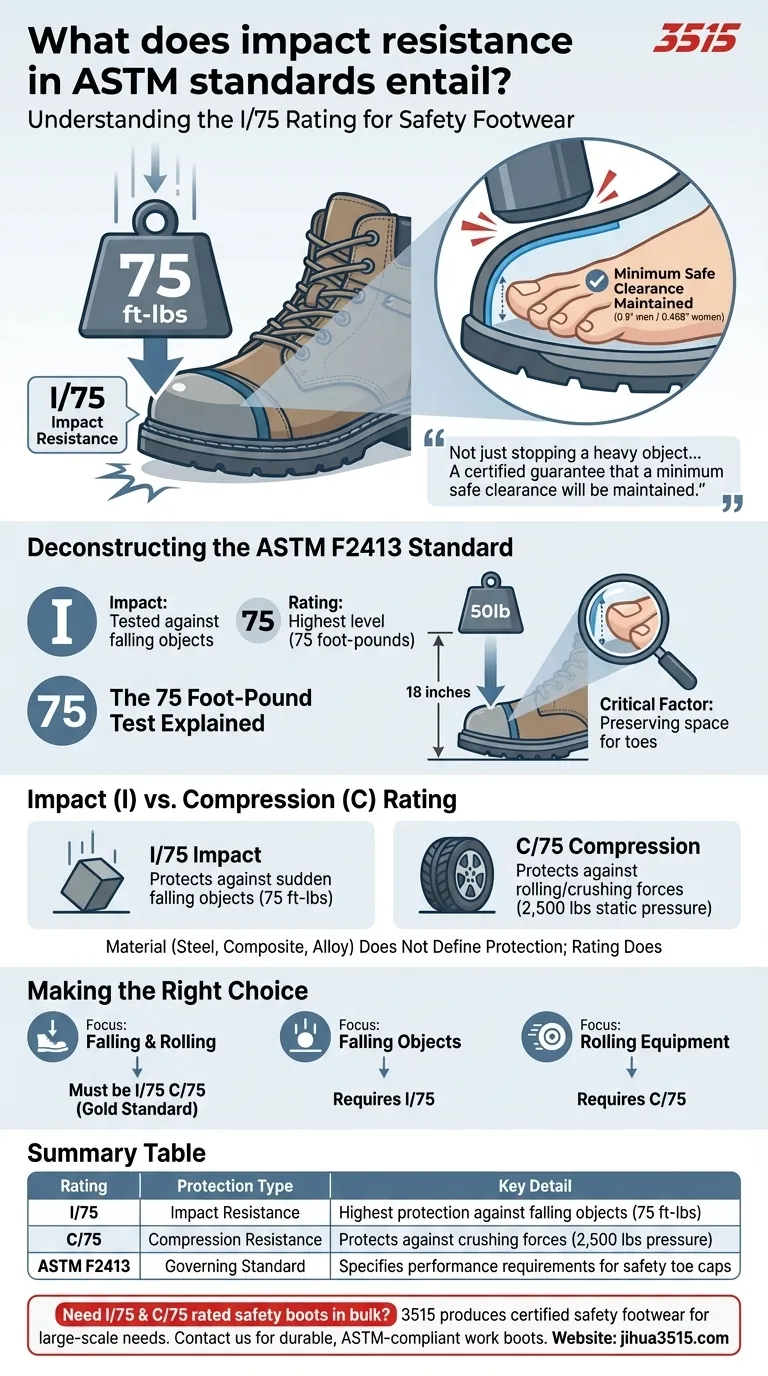

In short, impact resistance in ASTM standards signifies that the protective toe cap of a work boot can withstand a significant, sudden force from a falling object. For safety footwear, the highest standard requires the toe area to resist an impact equivalent to 75 foot-pounds of energy, a rating denoted by the label "I/75".

The ASTM impact rating is not just about stopping a heavy object; it's a certified guarantee that a minimum safe clearance will be maintained inside the boot's toe box after impact, protecting the wearer's toes from being crushed.

Deconstructing the ASTM Impact Standard

The standard that governs this is ASTM F2413, the "Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear." This specification outlines the minimum requirements for the design, performance, testing, and classification of safety footwear.

What is the "I/75" Rating?

When you see a boot labeled I/75, it breaks down into two parts.

- 'I' stands for Impact. This indicates the boot has been tested to protect against falling objects.

- '75' is the rating level, representing 75 foot-pounds. This is the highest level of impact protection defined by the ASTM standard.

The 75 Foot-Pound Test Explained

The test is a controlled, scientific simulation of a heavy object falling onto the toe of the boot.

A weight of approximately 50 pounds is dropped from a height of about 18 inches, creating an impact of 75 foot-pounds of energy. The key measurement is not simply whether the toe cap breaks, but the amount of space left inside the cap after the impact.

Why Clearance is the Critical Factor

The true goal of a safety toe is to preserve space for your toes.

After the 75 foot-pound impact, the standard requires a minimum interior clearance to be maintained. For men's footwear, this is 0.5 inches, and for women's, it is 0.468 inches. This ensures that even if the cap deforms, it won't crush the foot.

Common Pitfalls and Related Standards

Understanding the impact rating is crucial, but it's only one piece of the safety puzzle. Misinterpreting the labels can lead to selecting inadequate protection.

Impact vs. Compression ("C") Rating

A common point of confusion is the difference between impact and compression resistance.

The Impact (I) rating protects against falling objects. The Compression (C) rating protects against rolling or crushing forces, such as a vehicle tire or a heavy cart rolling over the foot. The highest compression rating is C/75, meaning the toe cap can withstand 2,500 pounds of static pressure while maintaining the required clearance.

Material Does Not Define Protection

Steel-toe, composite-toe, and alloy-toe boots can all achieve the exact same I/75 C/75 rating.

The material choice affects other factors like weight, thermal conductivity, and electrical conductivity, but the level of certified impact protection is determined by the rating, not the material itself.

Making the Right Choice for Your Goal

Look for the ASTM F2413 label inside the boot to confirm its specific protections. Your choice should be dictated by the primary hazards of your work environment.

- If your primary focus is maximum protection against falling and rolling objects: Ensure the boot is labeled I/75 C/75. This is the gold standard for most construction and industrial sites.

- If your primary focus is protection from falling tools or materials: The I/75 rating is your critical requirement.

- If you work around heavy rolling equipment but have a lower risk of falling objects: The C/75 rating is essential, though most top-tier safety boots will include both.

Choosing the right footwear is a critical step in ensuring your personal safety on the job.

Summary Table:

| Rating | Protection Type | Key Detail |

|---|---|---|

| I/75 | Impact Resistance | Highest protection against falling objects (75 ft-lbs). |

| C/75 | Compression Resistance | Protects against crushing forces (2,500 lbs of pressure). |

| ASTM F2413 | Governing Standard | Specifies performance requirements for safety toe caps. |

Need I/75 & C/75 rated safety boots in bulk? As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We ensure your workers get the highest level of protection with our reliable production capabilities. Contact us today for a quote and secure your supply of durable, ASTM-compliant work boots!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- Why is it necessary to equip workers with heavy-duty work boots? Essential Safety for Industrial & Construction Sites

- What are the key advantages of rubber work boots? Unbeatable Protection for Wet & Hazardous Environments

- How do work boots provide impact and compression resistance? The Science Behind the Protective Toe Cap

- What are the cons of Injection-Molded Construction? Weighing Durability Against Flexibility & Breathability

- Why should management prioritize certified high-quality safety boots? Enhance Safety Barriers & Operational Reliability

- What tips can help ensure a proper fit for work boots? A Guide to All-Day Comfort & Safety

- What care tips are recommended for maintaining Clarks desert boots? Essential Guide for Leather & Suede

- Why is investing in quality PVC work boots important for workplace safety? Protect Your Workforce with 3515 Footwear