In the language of safety footwear, the abbreviations stamped on your boots are a direct-to-the-point summary of their protective capabilities. P signifies a steel midsole plate for puncture resistance, PL or PS indicates a non-metallic (e.g., composite or fabric) puncture-resistant plate, and WR means the footwear is certified as water-resistant.

Understanding these codes is more than a technical exercise; it's about systematically matching a shoe's certified protections—from puncture-proofing to slip resistance—to the precise risks present in your work environment.

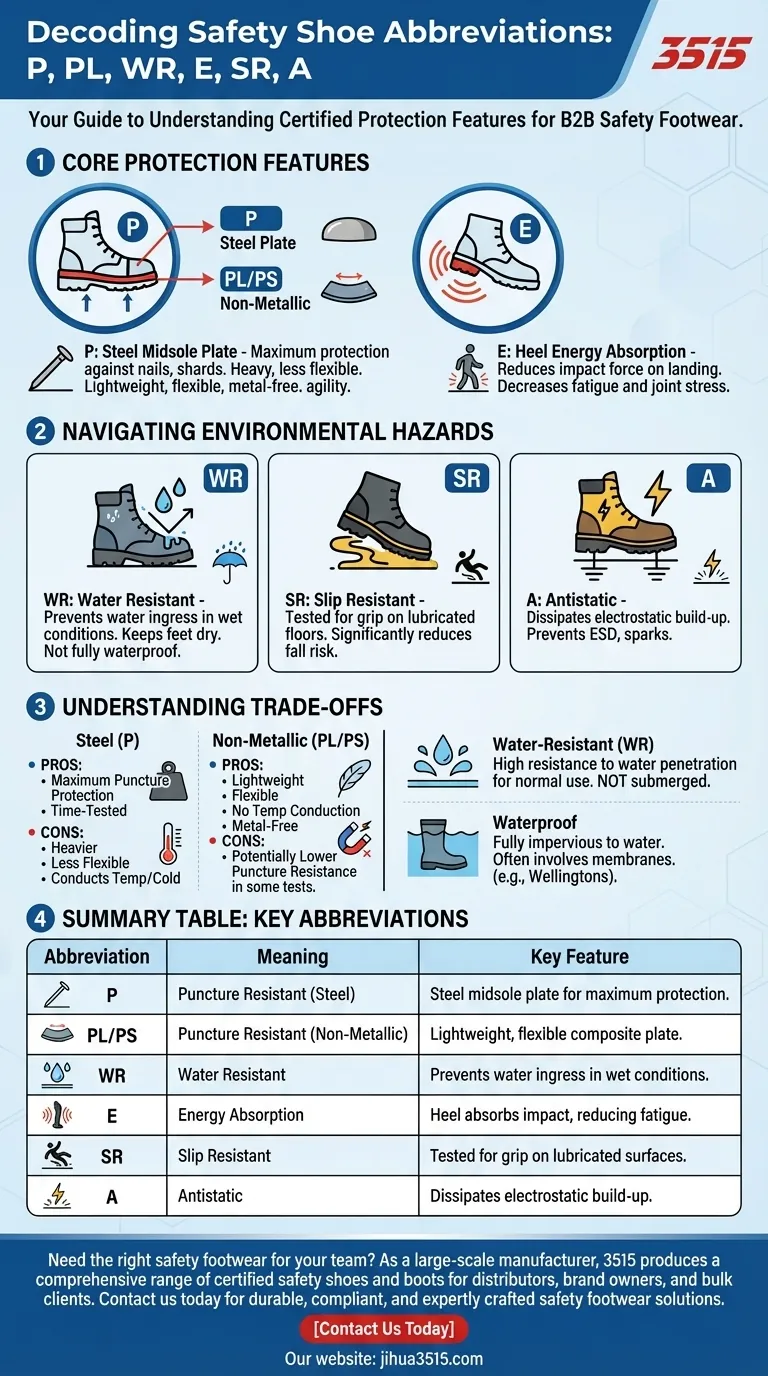

Decoding Core Protection Features

The most fundamental purpose of safety footwear is to protect against direct physical harm. The codes for puncture resistance and energy absorption are central to this mission.

Puncture Resistance (P, PL, PS)

The P marking indicates the presence of a steel plate in the midsole, designed to protect the foot from sharp objects like nails or metal shards penetrating from below.

Alternatively, PL and PS markings denote non-metallic puncture protection. These are typically made from materials like tightly woven fabrics (e.g., Kevlar) or composites, offering a more flexible and lightweight alternative to steel.

Heel Energy Absorption (E)

The E marking signifies that the heel region of the footwear is designed to absorb impact energy. This feature reduces the force transmitted to the wearer's body when walking or landing on hard surfaces, which can decrease fatigue and long-term joint stress.

Navigating Environmental Hazards

Beyond direct impacts, safety footwear must protect you from the specific conditions of your workplace. These markings address environmental risks like slips, water, and static electricity.

Water Resistance (WR)

Footwear marked with WR has been constructed and tested to prevent water from penetrating the interior. This is crucial for keeping feet dry and comfortable in wet working conditions, helping to prevent health issues.

Slip Resistance (SR)

The SR code is one of the most critical safety markings. It certifies that the outsole has been tested and has met a specific standard for slip resistance on lubricated surfaces, significantly reducing the risk of falls.

Antistatic Properties (A)

Footwear with an A marking is antistatic. It is designed to dissipate electrostatic build-up, reducing the risk of electrostatic discharge (ESD). This is vital in environments where a spark could damage sensitive electronic components or ignite flammable materials.

Understanding the Trade-offs

Choosing the right features often involves balancing competing priorities. The most common trade-off involves the material used for puncture protection.

Steel vs. Non-Metallic Plates (P vs. PL)

Steel plates (P) offer maximum, time-tested protection against puncture threats. However, they are heavier, less flexible, and can conduct heat and cold, which can be a disadvantage in extreme temperatures.

Non-metallic plates (PL/PS) provide greater flexibility, are significantly lighter, and do not conduct temperature. This makes them ideal for jobs requiring more agility or long hours of walking. They are also essential for environments with metal detectors.

"Water-Resistant" is Not "Waterproof"

It is critical to understand that WR (Water-Resistant) does not mean the boot is fully waterproof like a rubber wellington. It signifies a high level of resistance to water ingress during normal use but may not withstand full submersion for extended periods.

Making the Right Choice for Your Environment

Your selection should be driven entirely by the known hazards of your specific role and worksite.

- If your primary focus is construction or waste management: Prioritize

P(steel puncture) for maximum protection against nails and sharp debris, combined withEfor shock absorption on hard surfaces. - If your primary focus is logistics, aviation, or indoor manufacturing:

PL(non-metallic) plates offer lighter and more flexible protection, whileSR(slip resistance) is paramount on smooth floors. - If your primary focus is electronics assembly or work in explosive atmospheres:

A(antistatic) properties are a non-negotiable requirement to prevent electrostatic discharge. - If your primary focus is outdoor work in varied weather:

WR(water resistance) is essential for comfort and health, paired withSRto handle wet and slippery ground conditions.

By decoding these essential markings, you can confidently select footwear that actively mitigates the specific risks of your job.

Summary Table:

| Abbreviation | Meaning | Key Feature |

|---|---|---|

| P | Puncture Resistant (Steel) | Steel midsole plate for maximum protection |

| PL/PS | Puncture Resistant (Non-Metallic) | Lightweight, flexible composite plate |

| WR | Water Resistant | Prevents water ingress in wet conditions |

| E | Energy Absorption | Heel absorbs impact, reducing fatigue |

| SR | Slip Resistant | Tested for grip on lubricated surfaces |

| A | Antistatic | Dissipates electrostatic build-up |

Need the right safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring you get the precise combination of features—like P, PL, WR, SR, and A—to mitigate your specific workplace hazards.

Contact us today for durable, compliant, and expertly crafted safety footwear solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.