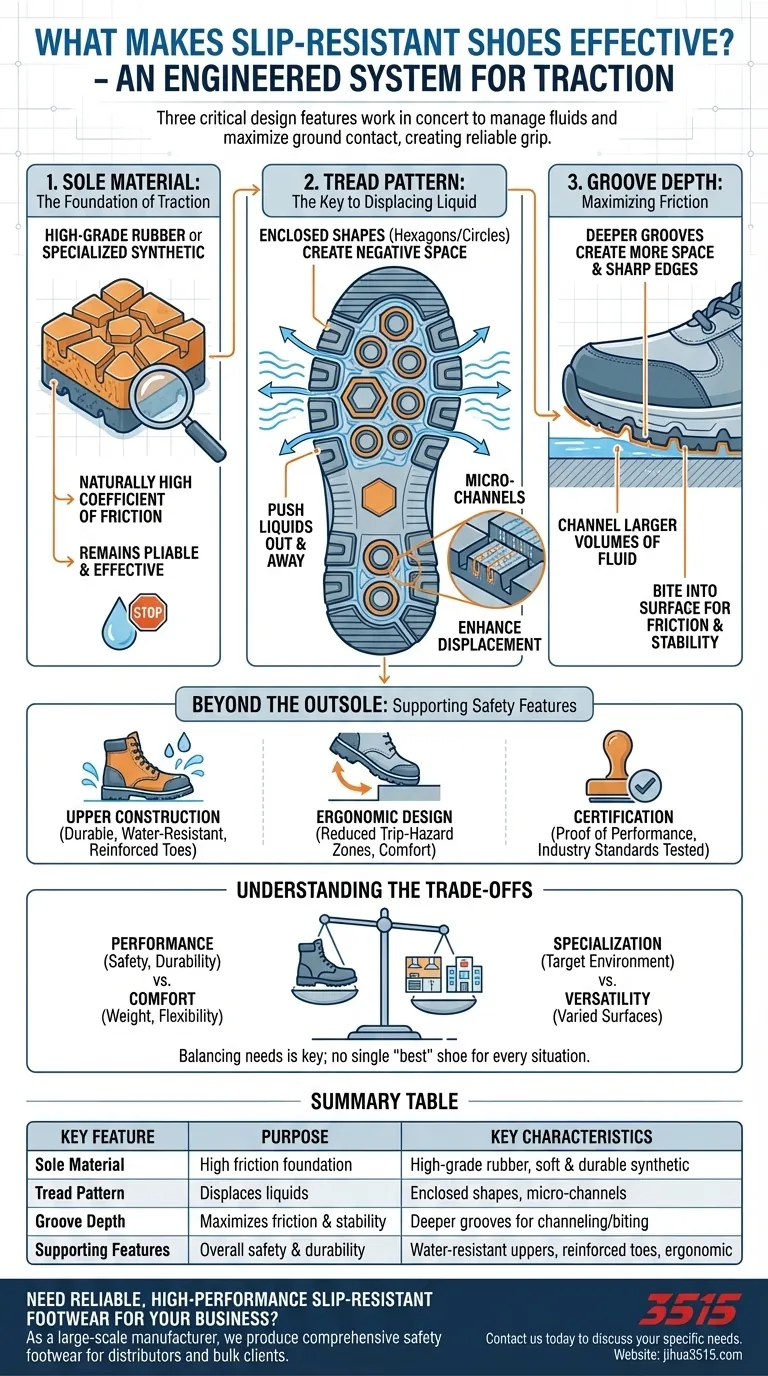

At its core, an effective slip-resistant shoe is defined by three critical design features: the material of the outsole, the specific pattern of its tread, and the depth of its grooves. These elements work in concert to manage fluids and maximize the shoe's contact with the ground, creating reliable traction where ordinary shoes would fail.

The central purpose of a slip-resistant shoe is not simply to be "sticky." Instead, its design is an engineered system for displacing the thin layer of liquid—be it water, oil, or grease—that causes hydroplaning and leads to dangerous falls.

The Science of Grip: Deconstructing the Outsole

The effectiveness of a slip-resistant shoe is determined almost entirely by the design and material of its outsole, the part that makes direct contact with the floor.

Sole Material: The Foundation of Traction

The journey to superior grip begins with the right material. High-quality slip-resistant shoes almost always use a soft, durable high-grade rubber or a specialized synthetic compound like polyurethane.

These materials have a naturally high coefficient of friction, which means they are better at gripping surfaces even before considering tread design. They remain pliable and effective across various temperatures.

Tread Pattern: The Key to Displacing Liquid

The most visible feature of a slip-resistant shoe is its intricate tread pattern. This is not for aesthetics; it's a crucial fluid-channeling system.

Effective designs often use enclosed shapes like hexagons or circles. When you step down, these patterns create negative space that pushes liquids out and away from the sole, allowing more of the shoe to make direct contact with the solid floor.

Some advanced designs also incorporate micro-channels within the larger tread blocks, which further enhance this water-displacement effect for maximum grip.

Groove Depth: Maximizing Friction

Simply having a pattern isn't enough; the depth of the grooves is equally important. Deeper grooves serve two primary functions.

First, they create more space to channel away larger volumes of fluid. Second, they create more sharp edges on the sole, which bite into the surface and significantly increase friction and stability.

Beyond the Outsole: Supporting Safety Features

While the outsole does the heavy lifting, other design elements contribute to the shoe's overall safety and performance in a professional environment.

Upper Construction: Durability and Protection

The upper part of the shoe must be able to withstand demanding conditions. Look for durable, water-resistant materials that protect your feet from spills.

Many work-specific shoes also feature reinforced toes and sturdy construction to endure the rigors of fast-paced or heavy-duty tasks.

Ergonomic Design: Reducing Other Hazards

Advanced safety shoes consider more than just slips. Some feature reduced trip-hazard zones—smoother areas on the very edge of the sole—to allow for easier movement between different surfaces, like from a carpeted area to a tiled kitchen.

Groove patterns that mimic the foot's natural motion are also used to enhance comfort during long shifts, reducing fatigue that can lead to accidents.

Certification: The Proof of Performance

The most reliable way to identify a true slip-resistant shoe is to look for explicit labeling or certification. This indicates the shoe has been tested against industry standards for slip resistance and has passed.

Understanding the Trade-offs

Choosing a slip-resistant shoe involves balancing pure performance with other practical needs. There is no single "best" shoe for every situation.

Performance vs. Comfort

The very features that enhance safety—thick, durable soles and deep treads—can make a shoe heavier and less flexible than everyday footwear. While modern designs have improved comfort, a trade-off often remains.

Specialization vs. Versatility

A shoe with a tread pattern designed for dispersing water in a hospital hallway may perform differently than one designed for greasy kitchen floors. Highly specialized treads offer the best performance in their target environment but may be less effective elsewhere.

How to Choose the Right Shoe

Your choice should be dictated entirely by the specific hazards of your environment.

- If your primary focus is wet or greasy floors (e.g., kitchens, food service): Prioritize shoes with intricate, enclosed tread patterns and micro-channels specifically designed to displace liquids.

- If your primary focus is moving between different floor types (e.g., healthcare, logistics): Look for a versatile design with reduced trip-hazard zones to ensure smooth and safe transitions.

- If your primary focus is durability on varied surfaces (e.g., light industrial, workshops): Select a shoe with deep grooves and a tough, high-grade rubber sole that provides both grip and support.

Ultimately, understanding these design principles empowers you to look past marketing and identify the features that will genuinely keep you safe on your feet.

Summary Table:

| Key Feature | Purpose | Key Characteristics |

|---|---|---|

| Sole Material | High friction foundation | High-grade rubber, soft & durable synthetic compounds |

| Tread Pattern | Displaces liquids | Enclosed shapes (hexagons/circles), micro-channels |

| Groove Depth | Maximizes friction & stability | Deeper grooves for fluid channeling and surface biting |

| Supporting Features | Overall safety & durability | Water-resistant uppers, reinforced toes, ergonomic design |

Need reliable, high-performance slip-resistant footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant shoes and boots, engineered with the precise outsole materials, tread patterns, and safety features detailed above.

We can help you provide superior traction and protection for your customers. Contact us today to discuss your specific needs and explore our manufacturing solutions.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- Can regular shoes be made slip-resistant? The Truth About Temporary Fixes vs. Engineered Safety

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- How can you perform a slip test on shoes you already own? A Guide to Safer Footwear

- What role do specialized anti-slip cleats on the soles of professional footwear play in preventing injuries? Stability

- How do slip-resistant shoes benefit older individuals? Prevent Falls and Enhance Stability

- What types of work environments are particularly prone to slippery floors? Prevent Slip-and-Fall Accidents

- What is the significance of tread patterns in non-slip shoes? Prevent Slips with Expert Sole Design