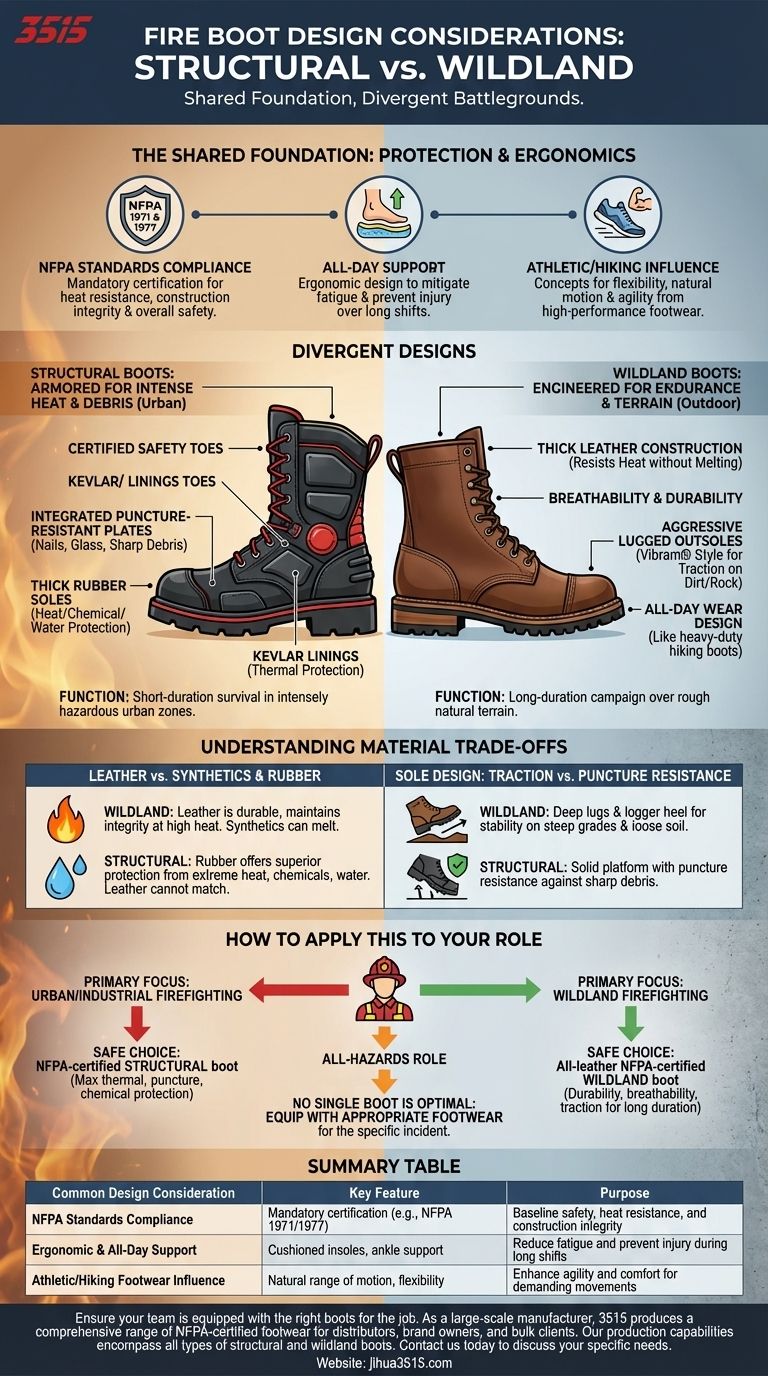

At their core, both structural and wildland fire boots share a common design philosophy rooted in three key areas: they must adhere to specific National Fire Protection Association (NFPA) safety standards, they are engineered with flexibility to support a firefighter’s various movements, and they often incorporate ergonomic principles from high-performance athletic and hiking footwear to ensure support during long periods of use.

While both boot types share the fundamental goal of protecting the firefighter, their designs diverge significantly based on the environment. A structural boot is built like armor for an intense, short-duration battle, while a wildland boot is built like an expedition tool for a long-duration campaign over rough terrain.

The Shared Foundation: Protection and Ergonomics

Every design decision in firefighter footwear starts with the same non-negotiable goals: ensuring the user's safety and enabling them to perform their job effectively without being hindered by their equipment.

Adherence to NFPA Standards

The most critical commonality is the mandatory compliance with NFPA standards. These regulations set the baseline for performance, dictating minimum requirements for heat resistance, construction integrity, and overall safety.

Though the specific standards differ (e.g., NFPA 1971 for structural, NFPA 1977 for wildland), the principle of third-party certified protection is universal.

The Need for All-Day Support

Firefighters spend immense amounts of time on their feet in unpredictable situations. Both boot categories are designed for ergonomic support to mitigate fatigue and prevent injury over long shifts.

This focus on comfort and support is a direct response to the physical demands of the job, whether climbing a ladder or hiking a fire line.

Influence from Athletic and Hiking Footwear

To achieve the required support and flexibility, designers for both boot types borrow concepts from athletic and hiking shoes.

This includes features like cushioned insoles, ankle support systems, and designs that allow for a more natural range of motion, which are critical for agility.

Divergent Designs for Different Battlegrounds

The specific hazards of an urban structure fire versus a forest fire are vastly different, demanding highly specialized features. This is where the designs diverge dramatically.

Structural Boots: Armored for Intense Heat and Debris

Structural boots are built for urban environments. They function as armor against extreme heat, falling debris, and hazardous materials.

Key features include thick rubber soles, integrated puncture-resistant plates, certified safety toes, and often Kevlar linings for thermal protection. Their primary function is short-term survival in an intensely hazardous zone.

Wildland Boots: Engineered for Endurance and Terrain

Wildland boots are made for the outdoors. They prioritize breathability, durability, and stability for walking long distances over uneven ground.

They are constructed almost exclusively from thick leather, which resists heat without melting. They feature aggressive lugged outsoles like Vibram for superior traction and are designed more like heavy-duty hiking boots for all-day wear.

Understanding the Material Trade-offs

The choice of materials is not arbitrary; it represents a critical trade-off between different types of protection. Using one boot in the wrong environment can be exceptionally dangerous.

Leather vs. Synthetics and Rubber

Wildland boots rely on leather because it is incredibly durable and maintains its structural integrity at high temperatures. Synthetic materials used in many standard hiking boots can liquify and melt when exposed to radiant heat from a fire line.

Conversely, the thick rubber construction of structural boots provides superior protection from extreme heat, chemicals, and water found in building fires, a level of protection leather cannot match.

Sole Design: Traction vs. Puncture Resistance

The sole of a wildland boot is designed for traction on dirt, rock, and loose soil. The deep lugs and specific heel profile (like a "logger" style) provide stability on steep grades.

A structural boot's sole is a solid platform built for puncture resistance. It's designed to protect the foot from nails, glass, and sharp metal debris common on a fire ground, a hazard that is far less prevalent in a wildland setting.

How to Apply This to Your Role

Understanding these distinctions is essential for ensuring you have the correct personal protective equipment for the specific hazard you face.

- If your primary focus is urban or industrial firefighting: Your only safe choice is an NFPA-certified structural boot that provides maximum thermal, puncture, and chemical protection.

- If your primary focus is wildland firefighting: You require the durability, breathability, and specialized traction of an all-leather NFPA-certified wildland boot designed for long-duration wear on natural terrain.

- If you operate in an all-hazards role: Recognize that no single boot is optimal for both scenarios; you must equip yourself with the appropriate footwear for the specific incident you are responding to.

Ultimately, your choice of footwear is a critical piece of life-saving equipment tailored to a specific and dangerous environment.

Summary Table:

| Common Design Consideration | Key Feature | Purpose |

|---|---|---|

| NFPA Standards Compliance | Mandatory certification (e.g., NFPA 1971/1977) | Baseline safety, heat resistance, and construction integrity |

| Ergonomic & All-Day Support | Cushioned insoles, ankle support | Reduce fatigue and prevent injury during long shifts |

| Athletic/Hiking Footwear Influence | Natural range of motion, flexibility | Enhance agility and comfort for demanding movements |

Ensure your team is equipped with the right boots for the job. As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of structural and wildland boots, designed with the safety and performance features detailed above. Contact us today to discuss your specific needs and how we can support your firefighting operations with high-quality, reliable footwear.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- In what areas are manufacturers innovating for fire boots? Boost Firefighter Performance & Safety

- Which material is the most durable for work boots? Find the Right Boot for Your Job

- What makes moc toe boots suitable for work environments? Unmatched Comfort & Durability

- How do employer replacement rules impact the use of work boots? A Guide to Proactive Safety

- What are Yard boots designed for? Specialized Footwear for Stable & Farm Work

- What features should concrete workers look for in work boots? Essential Protection for Harsh Environments

- How much water pressure can waterproof boots withstand? A Guide to Waterproof Integrity

- Are Moc toe boots still in fashion? Invest in a Timeless Workwear Staple