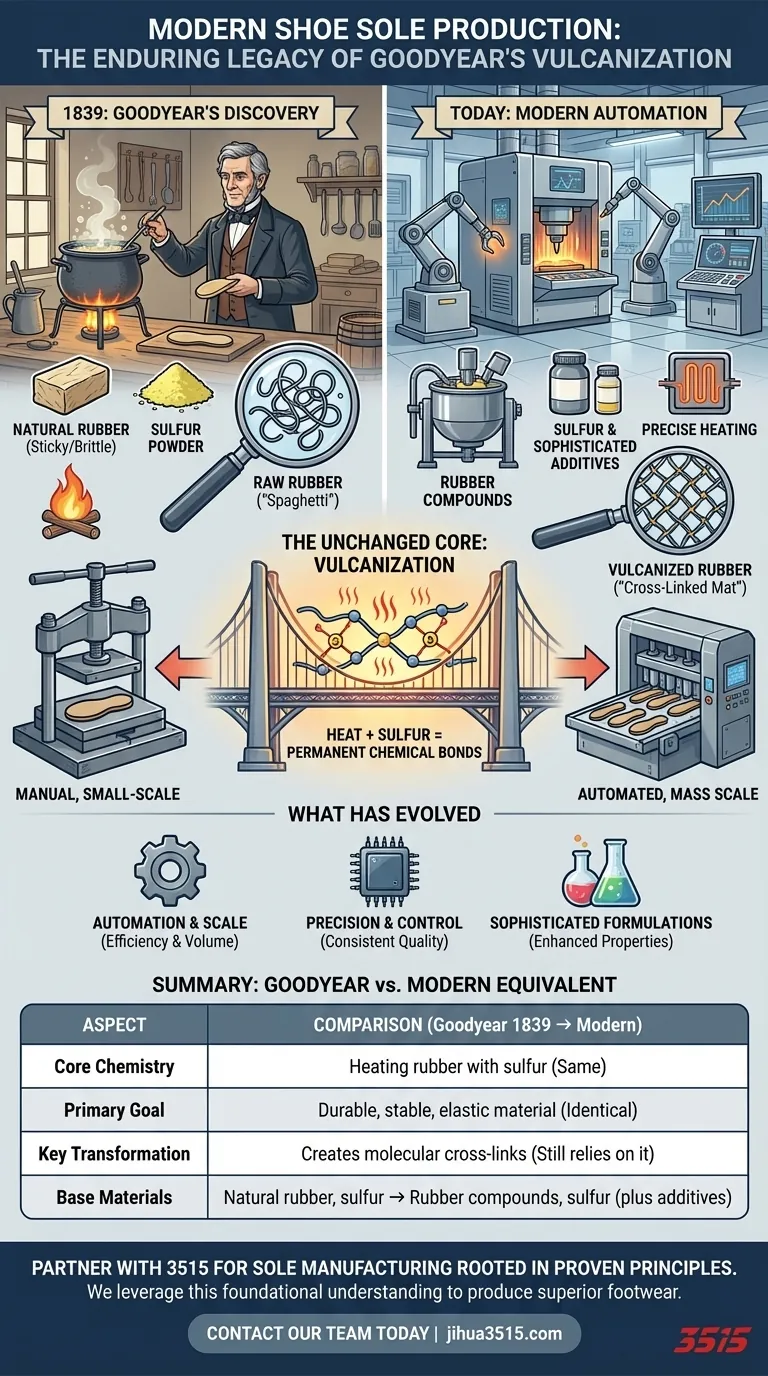

At its core, the modern production of rubber shoe soles remains remarkably similar to Charles Goodyear's original 1839 process because it is still centered on the fundamental chemical reaction he discovered: vulcanization. This method of heating rubber with sulfur to transform it from a sticky, unstable substance into a durable, elastic material is the foundational principle that has endured for over 150 years.

While the machinery, scale, and precision have been completely revolutionized, the essential chemistry that gives a shoe sole its strength and resilience is a direct legacy of Goodyear's initial breakthrough.

The Enduring Principle: What is Vulcanization?

To understand why this 19th-century process persists, we must first understand the problem it solved so elegantly.

The Problem with Natural Rubber

Before Goodyear, natural rubber was a fascinating but impractical material. It would melt into a sticky mess in the summer heat and become hard and brittle in the winter cold, making it useless for reliable products.

The Chemical Breakthrough

Goodyear's discovery, refined over years of experiments, was that adding sulfur to rubber and applying heat triggers a permanent chemical change. This process was named vulcanization, after Vulcan, the Roman god of fire.

Creating Molecular "Cross-Links"

Vulcanization works by creating strong chemical bonds, or cross-links, between the long, tangled polymer chains of natural rubber. Imagine raw rubber as a bowl of cooked spaghetti noodles; they can slide past each other easily. Vulcanization is like adding tiny knots that tie all the individual strands together into a single, cohesive, and resilient mat.

How the Core Process Persists Today

While factories look vastly different, the objective and the core chemical recipe for making a durable rubber sole have not fundamentally changed.

The Unchanged Chemistry

Modern sole production still relies on mixing a base rubber compound with sulfur and other agents. This mixture is then subjected to heat and pressure, which initiates the vulcanization process and "cures" the rubber into its final, stable form.

The Goal Remains the Same

The desired outcome is identical to Goodyear's original goal: to create a material that is waterproof, elastic, resistant to abrasion, and stable across a wide range of temperatures. These are the exact qualities that make a rubber sole effective.

Where Modern Production Diverges

The "how" has evolved dramatically, even if the "what" has not. The principles are the same, but the execution reflects over a century of industrial and technological advancement.

Automation and Scale

Goodyear's process was manual and small-scale. Today, massive, automated machinery handles the mixing, molding, and curing processes, allowing for the production of millions of soles with incredible efficiency.

Precision and Control

Modern manufacturing uses computerized systems to precisely control temperature, pressure, and curing times. This level of control ensures a highly consistent product quality that was impossible to achieve in the 19th century.

Sophisticated Formulations

While the core is still rubber and sulfur, today's formulas are complex. Modern chemists add specialized accelerators, pigments, and protective agents to enhance specific properties like UV resistance, grip, colorfastness, and cushioning far beyond what basic vulcanization could offer.

Applying This Understanding

Recognizing the legacy of vulcanization helps put modern manufacturing in context. It's a testament to a foundational discovery that was so effective it remains the bedrock of an industry.

- If your primary focus is on material science: Understand that creating polymer cross-links via vulcanization is a fundamental principle that transformed a natural polymer into a high-performance industrial material.

- If your primary focus is on industrial history: Recognize this as a prime example of how a single, robust chemical process can serve as the foundation for over a century of technological evolution and refinement.

- If your primary focus is on product design: Appreciate that the essential performance requirements for a shoe sole—durability, flexibility, and stability—are still delivered by the same basic chemical reaction discovered long ago.

Ultimately, every time you walk on a durable rubber sole, you are benefiting from a chemical process that has remained fundamentally unchanged since its discovery.

Summary Table:

| Aspect | Goodyear's Process (1839) | Modern Equivalent |

|---|---|---|

| Core Chemistry | Heating rubber with sulfur | Same fundamental vulcanization reaction |

| Primary Goal | Create durable, stable, elastic material | Identical performance requirements |

| Key Transformation | Creates molecular cross-links | Still relies on creating polymer cross-links |

| Base Materials | Natural rubber, sulfur | Rubber compounds, sulfur (plus modern additives) |

Partner with 3515 for Sole Manufacturing Rooted in Proven Principles

As a large-scale manufacturer, 3515 leverages this foundational understanding of vulcanization to produce superior footwear. We combine time-tested material science with modern precision and scale to deliver a comprehensive range of durable shoes and boots for distributors, brand owners, and bulk clients.

Let's build durable products together. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Wholesale Comfort Leather Business Shoes with Dial Lacing System

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What factors should be checked when trying on safety shoes? Ensure Perfect Fit & Maximum Protection

- Why is proper fit crucial for safety toe boots? Avoid These Hidden Hazards

- How can you determine the right safety toe boot for your workplace? Match Boots to Hazards

- What types of safety shoes are appropriate for different work environments? Choose the Right Protection for Your Job

- What are the key considerations for finding a perfect fitting safety toe boot? Avoid Injury and Discomfort