To understand the desert boot's enduring appeal, you must look at how it's made. The most common construction methods are stitch-down and cemented, with the occasional use of the San Crispino technique. These methods directly influence the boot's signature flexibility, durability, and lightweight feel.

The core principle of desert boot construction is not about a single mandatory method, but about achieving a functional harmony between a simple, lightweight upper and a soft, flexible sole—a design born from pure necessity.

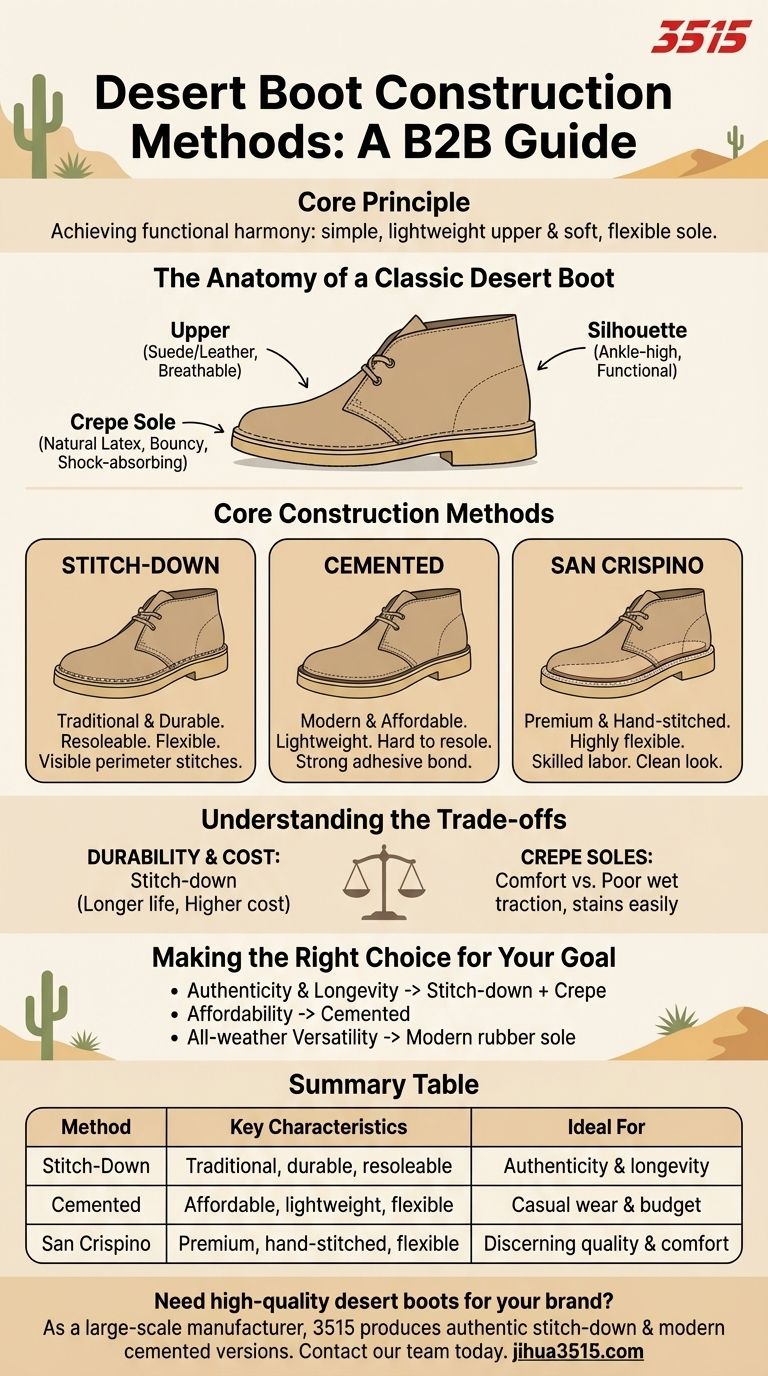

The Anatomy of a Classic Desert Boot

Before diving into construction methods, it's essential to understand the components that define the boot. Its design is a masterclass in simplicity and function, a direct legacy of its military origins.

The Upper: Lightweight and Unstructured

A traditional desert boot features an upper made from suede or soft leather. This choice prioritizes breathability and minimal weight. The design is simple, typically with just two or three pairs of eyelets and an open lacing system where the quarters are stitched on top of the vamp.

The Sole: The Signature Crepe

The most iconic feature of a classic desert boot is its crepe sole. This material is a form of natural coagulated latex, giving it a unique, gummy texture. The crepe sole provides exceptional bounce and comfort, acting as a natural shock absorber while offering a surprisingly firm grip on dry surfaces like sand.

The Silhouette: Function over Form

The boot's form is ankle-high with a rounded toe box. This straightforward silhouette was designed to be comfortable and prevent sand from getting in, while remaining light enough for soldiers to wear in the oppressive heat of the desert.

Core Construction Methods Explained

The way the upper is attached to the sole is the most critical step in its construction, defining both its feel and its lifespan.

Stitch-Down Construction

This is the most traditional and recognizable method for desert boots. The upper leather is turned outward and then stitched directly to the midsole or outsole. This technique creates a very flexible and durable boot, allowing the foot to move naturally. It is visually identified by the stitches running along the perimeter of the sole edge.

Cemented Construction

In a cemented construction, the upper is attached to the sole using a strong adhesive. This is a common, modern, and cost-effective method used in many types of footwear. While it creates a lightweight and flexible bond, it is generally less durable than a stitched construction and makes resoling the boot very difficult, if not impossible.

San Crispino Construction

Though less common, the San Crispino method is a premium construction technique. It involves hand-stitching the upper to an insole "sock," creating a clean and highly flexible shoe. This method is typically reserved for higher-end footwear due to the skilled labor it requires.

Understanding the Trade-offs

Choosing a desert boot involves more than just style; it means balancing authenticity, durability, and practicality.

Durability vs. Cost

Stitch-down construction offers superior durability and the potential for resoling, extending the boot's life significantly. Cemented boots are more affordable and widely available but should be viewed as having a finite lifespan once the sole wears out.

The Reality of Crepe Soles

While incredibly comfortable, crepe soles have practical limitations. They are porous and can absorb dirt and stains easily. They also offer poor traction in wet or icy conditions and can feel heavy compared to modern synthetic soles.

Material Maintenance

The classic suede upper gives the desert boot its casual elegance but requires more care than smooth leather. Suede is susceptible to water stains and scuffs, necessitating regular brushing and protective sprays to maintain its appearance.

Making the Right Choice for Your Goal

Your ideal desert boot depends entirely on what you value most.

- If your primary focus is authenticity and longevity: Seek out a boot with a traditional stitch-down construction and a genuine crepe sole.

- If your primary focus is affordability for casual wear: A cemented construction offers the classic desert boot look at a more accessible price point.

- If your primary focus is all-weather versatility: Consider modern interpretations with leather uppers and standard rubber soles that sacrifice some classic comfort for improved durability and traction.

By understanding how a desert boot is built, you can confidently select a pair that truly aligns with your needs for style, comfort, and longevity.

Summary Table:

| Construction Method | Key Characteristics | Ideal For |

|---|---|---|

| Stitch-Down | Traditional, durable, resoleable | Authenticity & longevity |

| Cemented | Affordable, lightweight, flexible | Casual wear & budget |

| San Crispino | Premium, hand-stitched, highly flexible | Discerning quality & comfort |

Need high-quality desert boots for your brand or store?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including authentic stitch-down desert boots and modern cemented versions. We can help you deliver the perfect balance of style, comfort, and durability to your customers.

Contact our team today to discuss your production needs and get a quote.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How should bit loafers be styled for a business casual outfit? A Guide to Polished Versatility

- Why are chelsea boots considered a versatile style? The Ultimate Wardrobe Foundation

- What are the characteristics of loafers as business casual shoes? The Perfect Blend of Style and Comfort

- How can business casual footwear be adapted for different seasons? Master Material Selection for Year-Round Style

- What are the features of Derby shoes? A Guide to Versatile and Comfortable Footwear

- What is the desert boot considered in terms of style? The Ultimate Guide to Sharp Casual Footwear

- Are chukka boots stylish? The Ultimate Guide to Timeless, Versatile Footwear

- How did chukka boots transition from sport to civilian wear? From Polo Fields to Mainstream Fashion