The two primary types of outsoles used in vulcanized footwear are the calendar sole and the molded sole. Both are constructed from uncured rubber and are permanently bonded to the shoe's upper during a high-heat vulcanization process, but their initial creation method is fundamentally different.

While both calendar and molded soles are unified with the shoe through the same vulcanization process, the choice between them comes down to a fundamental trade-off: manufacturing efficiency versus design complexity.

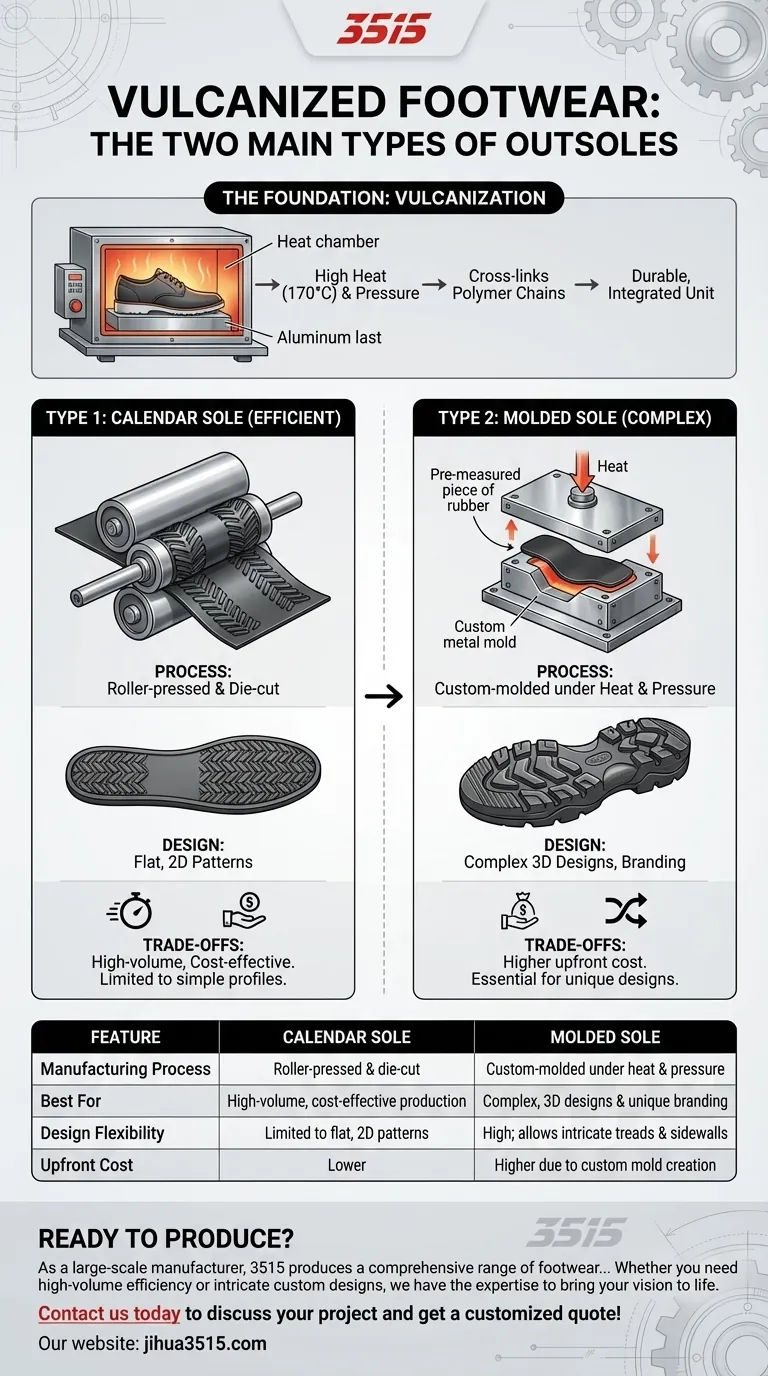

The Foundation: The Vulcanization Process

To understand the difference in outsoles, you must first understand the process that defines the shoe. Vulcanization is not just about gluing parts together; it's about chemically fusing them into a single, integrated unit.

What is Vulcanization?

Vulcanization uses high heat (often around 170°C) and pressure to create cross-links between polymer chains in the rubber. This chemical reaction transforms soft, uncured rubber components into a single, durable, and elastic piece.

This process is what gives classic vulcanized shoes their signature flexibility, wear-resistance, and anti-skid properties.

The Role of the Last

During this process, the shoe is assembled on an aluminum last. Aluminum is used because it can withstand the intense heat of the vulcanizing oven and distribute it evenly, ensuring a consistent and permanent bond between the outsole, the foxing tape, and the shoe's upper.

Deconstructing the Outsole Types

The key difference between the two outsole types happens before they are attached to the upper for baking. It’s all in how the initial rubber shape is formed.

Type 1: The Calendar Sole

A calendar sole is created by feeding a sheet of uncured rubber through a large, dual-roller press. This process is called calendering.

One roller is smooth, while the other is engraved with the repeating tread pattern. As the rubber passes through, the pattern is imprinted onto the sheet.

This long, patterned sheet is then cooled, and individual outsoles are die-cut from it, much like cutting cookies from a sheet of dough.

Type 2: The Molded Sole

A molded sole is used for more complex or three-dimensional designs that a simple roller cannot create.

Here, a pre-measured piece of uncured rubber is placed into a custom-made metal mold. The mold is then closed and subjected to heat and pressure, forcing the rubber to fill every detail of the cavity.

This method allows for intricate tread designs, varying depths, detailed logos, and unique sidewall textures that are impossible to achieve with calendering.

Understanding the Trade-offs

The choice between a calendar and a molded sole directly impacts manufacturing cost, speed, and design possibilities.

Manufacturing and Cost

Calendar soles are highly efficient for mass production. The continuous rolling and cutting process is fast and cost-effective, making it ideal for classic, high-volume footwear with simple, flat outsoles.

Molded soles require significant upfront investment in creating precise, durable molds for each shoe size and design. This makes the initial cost higher, but it's necessary for achieving unique sole units.

Design and Complexity

The primary limitation of a calendar sole is its flatness. The pattern is simply pressed onto a sheet, restricting it to two-dimensional, repeating designs.

The major advantage of a molded sole is design freedom. It unlocks the potential for complex, three-dimensional geometry, custom branding, and performance-oriented tread patterns.

Making the Right Choice for Your Goal

Understanding this distinction is critical for footwear design and production. Your final goal dictates the correct manufacturing path.

- If your primary focus is cost-effective, high-volume production with a classic, flat profile: Calendar soles are the industry standard for their unmatched efficiency.

- If your primary focus is creating unique tread patterns, detailed sidewalls, or complex branding: Molded soles provide the essential design flexibility, despite higher initial costs.

Ultimately, knowing how an outsole is formed is the first step to controlling the final look, feel, and performance of the shoe.

Summary Table:

| Feature | Calendar Sole | Molded Sole |

|---|---|---|

| Manufacturing Process | Roller-pressed and die-cut from a sheet | Custom-molded under heat and pressure |

| Best For | High-volume, cost-effective production | Complex, 3D designs and unique branding |

| Design Flexibility | Limited to flat, 2D patterns | High; allows intricate treads and sidewalls |

| Upfront Cost | Lower | Higher due to custom mold creation |

Ready to produce your next line of vulcanized footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including both calendar and molded sole options. Whether you need high-volume efficiency or intricate custom designs, we have the expertise to bring your vision to life.

Contact us today to discuss your project and get a customized quote!

Visual Guide

Related Products

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

People Also Ask

- What is a stylish way to wear heeled lace-up boots? Master the Art of Stylish Contrast

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- How can tall socks enhance the look of lace-up boots? Add Style, Color & Texture

- How have sneaker brands incorporated camouflage patterns? From Military to Streetwear Style

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage