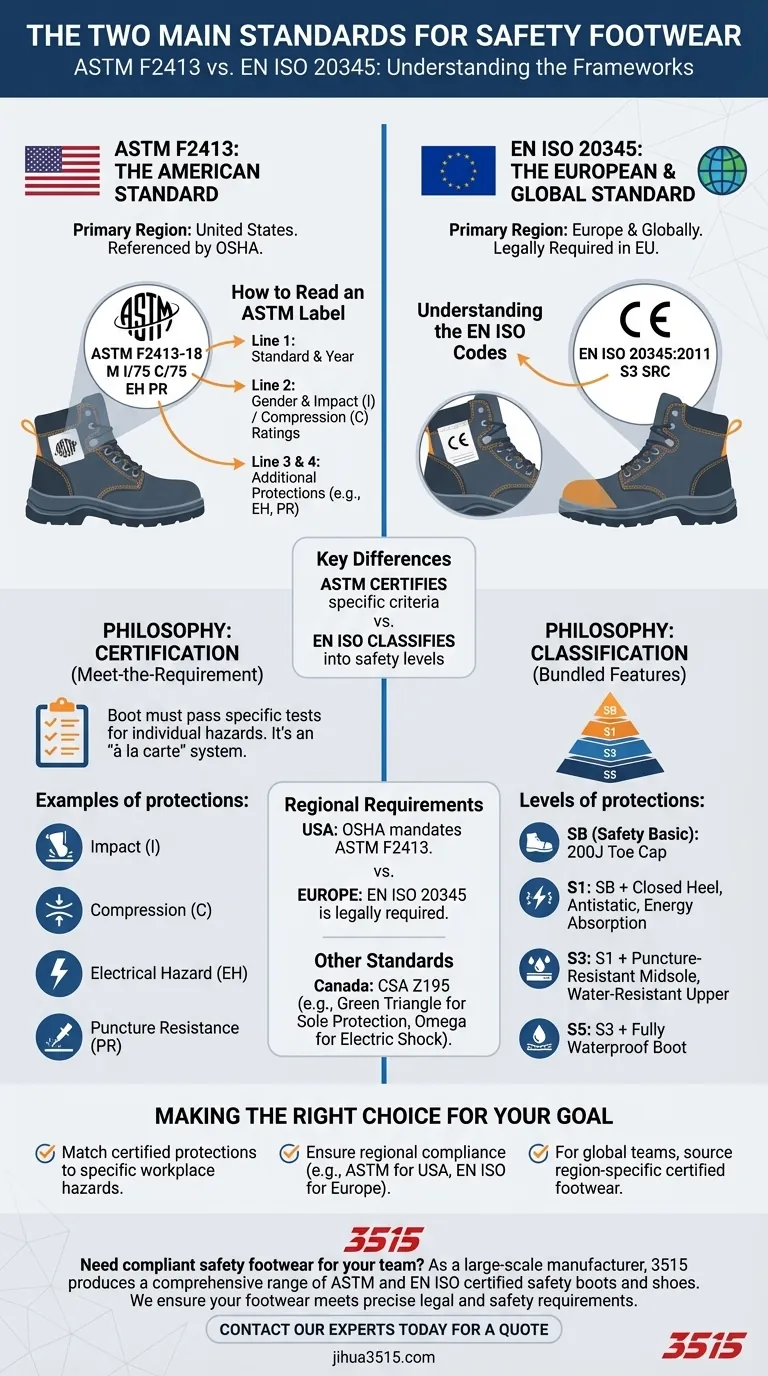

In safety footwear, the two most recognized standards are the American Society for Testing and Materials (ASTM) F2413, used primarily in the United States, and the International Organization for Standardization's EN ISO 20345, which is the standard across Europe and widely adopted globally. Both frameworks provide a systematic way to test and certify footwear for specific workplace hazards like impact, compression, and punctures.

The core difference lies in their approach: ASTM F2413 certifies that a shoe meets specific performance criteria, while EN ISO 20345 classifies footwear into different safety levels (like S1, S3, S5) based on the protections it includes. Understanding this distinction is key to selecting the appropriate footwear for your environment.

The Two Pillars of Safety Footwear Certification

ASTM F2413: The American Standard

The ASTM F2413 standard is the benchmark for safety toe cap footwear in the United States. It is the standard referenced by the Occupational Safety and Health Administration (OSHA).

It's important to note that ASTM does not "approve" or "certify" boots itself. Instead, it creates the testing standards that manufacturers must follow to prove their footwear provides a certain level of protection.

How to Read an ASTM Label

An ASTM F2413 label is a code that details the specific protections a boot offers. It typically follows a three- or four-line format.

- Line 1: Identifies the standard (

ASTM F2413) and the year of the standard it was tested against. - Line 2: Shows the gender (

M/F) and ratings for Impact (I) and Compression (C) resistance of the toe cap. - Line 3 & 4: List codes for any additional protections, such as

EHfor Electrical Hazard orPRfor Puncture Resistance.

EN ISO 20345: The European and International Standard

The EN ISO 20345 standard is required for safety footwear sold within the European Union and is recognized in many other parts of the world.

Unlike ASTM's à la carte system, EN ISO 20345 uses a classification system. All footwear certified under this standard must have a protective toe cap resistant to 200 joules of impact.

Understanding the EN ISO Codes

The core of this standard is its classification system, identified by a letter and number code.

- SB (Safety Basic): Meets the minimum requirement of a 200-joule impact-resistant toe cap.

- S1: Same as SB, plus has a closed heel area, antistatic properties, and energy absorption in the heel.

- S3: Includes all S1 protections, plus a puncture-resistant midsole and a water-resistant upper.

- S5: Offers the highest level of protection, including all S3 features in a fully waterproof polymer or rubber boot.

Understanding the Trade-offs and Key Differences

It's a common misconception that one standard is inherently "better" than the other. They are simply different frameworks for communicating the same goal: worker safety.

Certification vs. Classification

The most significant difference is the philosophy. ASTM F2413 is a "meet-the-requirement" standard. A boot either passes the test for a specific hazard (like Electrical Hazard) or it doesn't.

EN ISO 20345, on the other hand, is a classification system. A boot rated "S3" tells you it has a bundle of specific features (toe protection, puncture resistance, water resistance, etc.) all in one code.

Regional Requirements

The most critical factor in choosing is your location and workplace requirements. If you work in the United States, your employer will mandate compliance with ASTM F2413 as per OSHA guidelines. In Europe, the EN ISO 20345 standard is legally required.

What About Other Standards?

While ASTM and EN ISO are the two dominant forces, other regional standards exist. For example, Canada uses the CSA Z195 standard, which has its own specific codes for toe protection, sole protection (P), and electric shock resistance (Ω). Always defer to your local regulations.

Making the Right Choice for Your Goal

Selecting the correct footwear isn't about picking the "best" standard; it's about matching the shoe's certified protections to the specific hazards of your job.

- If your primary focus is compliance in the United States: Look for the ASTM F2413 label inside the footwear and ensure its specific codes (e.g., I/75, C/75, EH, PR) match your workplace safety assessment.

- If your primary focus is compliance in Europe or internationally: Look for the EN ISO 20345 marking and choose the appropriate classification (e.g., S1, S3) that covers all potential risks in your environment.

- If you are managing a global team: It is crucial to source footwear that is certified for the specific region where the work is being performed to ensure legal compliance.

Ultimately, safety standards are the language that footwear uses to communicate its protective capabilities, and learning to speak it is the first step toward a safer work environment.

Summary Table:

| Standard | Primary Region | Key Feature | Common Codes/Classifications |

|---|---|---|---|

| ASTM F2413 | United States | Certifies specific hazard protections (e.g., Impact, Compression) | I/75, C/75, EH, PR |

| EN ISO 20345 | Europe & Global | Classifies footwear into safety levels with bundled features | SB, S1, S3, S5 |

Need compliant safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM and EN ISO certified safety boots and shoes for distributors, brand owners, and bulk clients. We ensure your footwear meets the precise legal and safety requirements for your region and workplace hazards.

Contact our experts today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear

- Are employers required to provide steel-toe rubber boots at no cost to employees? Yes, under OSHA rules.