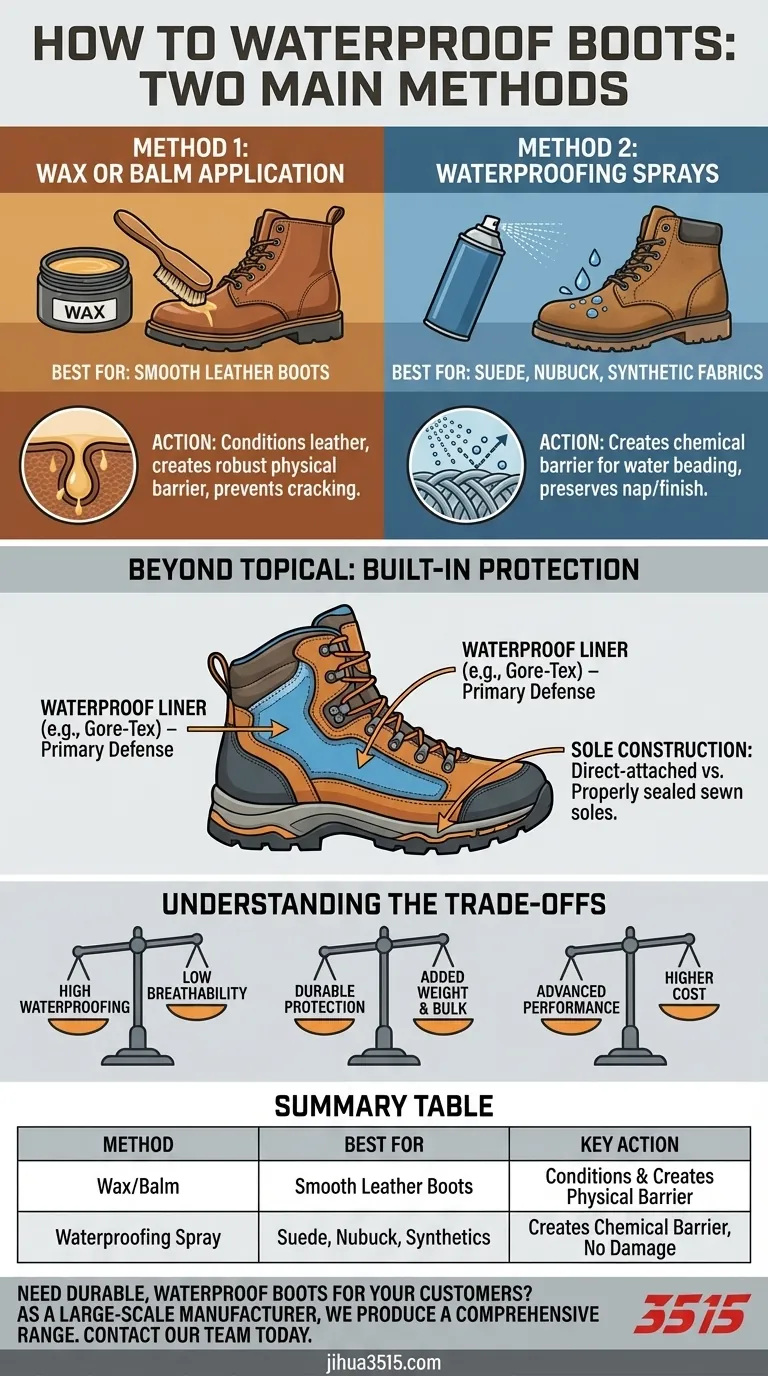

At its core, waterproofing boots involves two primary methods: applying a wax-based treatment or using a specialized waterproof spray. The correct choice is not about which is "better," but which is appropriate for your boot's specific material. Wax or balms are typically used for smooth leather, while sprays are essential for materials like suede, nubuck, and synthetic fabrics.

The fundamental challenge is balancing water resistance with breathability. While topical treatments are crucial for maintaining the outer material, the most effective waterproofing often comes from a boot's internal construction, like a waterproof liner.

The Two Core Waterproofing Methods

The method you choose is dictated entirely by the material of your boot's upper. Using the wrong product can be ineffective at best and damaging at worst.

Method 1: Wax or Balm Application

A wax or balm is a dense, conditioning treatment designed for smooth leather boots. It works by physically seeping into the leather's pores.

This creates a robust physical barrier that repels water. It also deeply conditions the leather, keeping it supple and preventing it from drying out and cracking over time.

Method 2: Waterproofing Sprays

Waterproofing sprays are the go-to solution for delicate or textured materials like suede, nubuck, and synthetic fabrics.

These sprays create a chemical barrier on the surface that causes water to bead up and roll off. A wax would ruin the nap of suede and mat down the fibers, making a spray the only viable option to preserve the boot's original finish.

Beyond Topical Treatments: Built-in Protection

True waterproofing often goes deeper than a surface-level application. The boot's internal design is the most critical factor for keeping your feet dry in harsh conditions.

The Role of Waterproof Liners

Many high-quality boots feature a built-in waterproof, breathable membrane (like Gore-Tex or a proprietary equivalent) sandwiched between the outer material and the inner lining.

This liner is your primary defense against water penetration. Topical treatments in this case serve to protect the outer leather or fabric, preventing it from getting waterlogged and heavy, which in turn helps the membrane breathe effectively.

How Sole Construction Matters

The way the sole is attached to the upper also impacts water resistance. Direct-attached soles that are bonded to the upper often create a more waterproof seal.

Conversely, boots with sewn soles (like a Goodyear welt) require the stitching to be properly sealed to prevent water from wicking in through the threads.

Understanding the Trade-offs

Achieving a waterproof boot always involves balancing competing priorities. Understanding these compromises is key to managing your expectations.

The Breathability Challenge

The more impermeable a boot is to water, the less breathable it tends to be. Materials like rubber or heavy wax coatings can trap sweat, leading to damp, uncomfortable feet even if no external water gets in.

Added Weight and Bulk

Highly waterproof boots, especially those designed for extreme weather, are often heavier and more rigid. This can cause discomfort and fatigue during long periods of wear.

The Cost of Performance

Boots that successfully combine high levels of waterproofing with good breathability typically use advanced materials and construction techniques. This engineering comes at a higher price point.

Making the Right Choice for Your Boots

Your goal dictates the best approach. Focus on a maintenance strategy that protects your specific footwear investment and ensures comfort.

- If your primary focus is protecting smooth leather boots: Use a high-quality wax or balm to create a durable barrier while simultaneously conditioning the material.

- If your primary focus is waterproofing suede, nubuck, or fabric boots: Rely on a specialized spray designed for these materials to avoid damaging their texture and appearance.

- If your boots already have a waterproof liner: Apply the appropriate external treatment (wax or spray) to maintain the outer material's health and prevent it from becoming saturated.

Properly maintaining your boots' water resistance is the single best way to protect your investment and keep your feet dry and comfortable.

Summary Table:

| Method | Best For | Key Action |

|---|---|---|

| Wax/Balm | Smooth Leather Boots | Conditions leather & creates a physical water barrier. |

| Waterproofing Spray | Suede, Nubuck, Synthetic Fabrics | Creates a chemical barrier without damaging delicate materials. |

Need durable, waterproof boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof shoes and boots, built with the right materials and construction methods for lasting performance.

Contact our team today to discuss your specific needs and explore our catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture