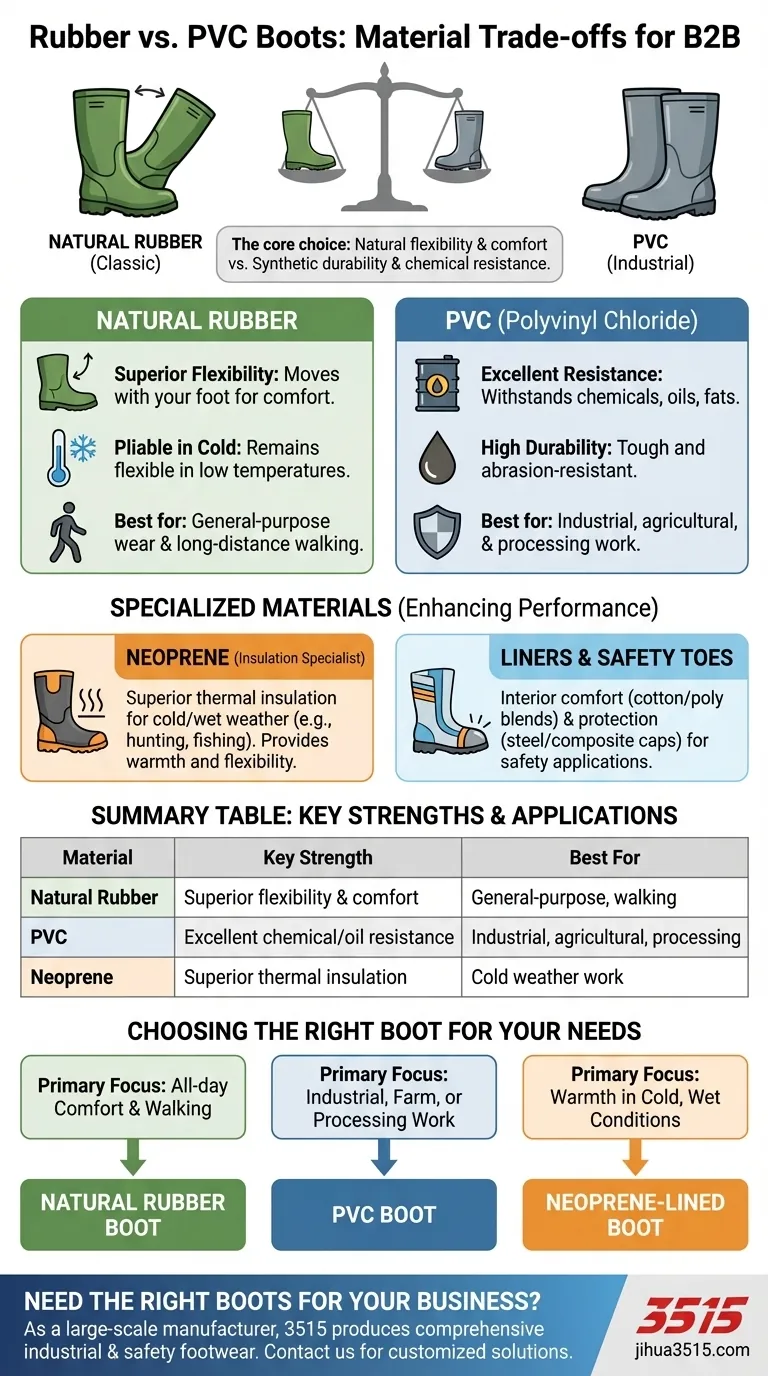

In short, the two main materials used to construct the body of modern "rubber boots" are Natural Rubber and PVC (Polyvinyl Chloride). While other materials like Neoprene are used for specific features like insulation, rubber and PVC represent the foundational choice you will make.

The decision between a rubber or PVC boot is not about finding a universally "better" option. It's a strategic choice based on a fundamental trade-off: natural flexibility and comfort versus synthetic durability and chemical resistance.

Understanding the Core Materials

Choosing the right boot begins with understanding the inherent properties of the two most common materials. Each is engineered with a different set of strengths tailored to specific environments.

Natural Rubber: The Classic Standard

Natural rubber is the traditional material for wellington boots, derived from the latex of rubber trees. Its primary advantage is its elasticity.

This natural flexibility allows the boot to move with your foot, providing a significantly more comfortable walking experience over long periods. It also performs well in cold temperatures, remaining pliable where other materials might become stiff.

PVC (Polyvinyl Chloride): The Industrial Workhorse

PVC is a synthetic plastic polymer. While less flexible than natural rubber, its key strength is its exceptional durability and resistance.

PVC is highly effective at resisting degradation from chemicals, acids, oils, and fats. This makes it the standard material for boots used in industrial, agricultural, or processing environments where exposure to such substances is common.

The Role of Specialized Materials

While rubber and PVC form the basis of most boots, other materials are integrated to enhance performance for specific conditions.

Neoprene: The Insulating Specialist

Neoprene is a type of synthetic rubber prized for its excellent thermal insulation properties.

You will often find Neoprene used in the upper portions of boots designed for cold weather. It keeps the wearer warm while remaining flexible, making it ideal for winter work, hunting, or fishing.

Liners and Safety Toes

The interior of a boot is typically lined with materials like cotton or a cotton/polyester blend for moisture absorption and comfort.

For safety applications, boots may also include protective toe caps. These are most often made from steel, a lighter composite material, or an aluminum alloy.

Key Differences and Trade-offs

Your choice directly impacts the boot's performance, comfort, and longevity. Understanding the trade-offs is critical.

Flexibility and Comfort

Natural rubber is the clear winner for general-purpose comfort. Its elasticity provides a better fit and reduces fatigue when walking. PVC can feel stiffer and less forgiving.

Chemical Resistance

PVC is the superior choice for any environment with chemical exposure. Natural rubber will degrade more quickly when exposed to oils, solvents, and certain farm chemicals.

Insulation and Weight

For warmth, Neoprene is the premier material. Standard rubber provides moderate insulation, while unlined PVC offers very little. However, PVC is often lighter than a comparable natural rubber boot, which can be a factor in reducing fatigue.

Choosing the Right Boot for Your Needs

To make the right decision, start by defining your primary use case. The environment dictates the material.

- If your primary focus is all-day comfort and walking: A natural rubber boot offers the best flexibility for general-purpose wear.

- If your primary focus is industrial, farm, or processing work: PVC provides the necessary resistance to chemicals, oils, and abrasion.

- If your primary focus is warmth in cold, wet conditions: Look for a boot constructed with Neoprene for its superior insulation.

Ultimately, selecting the right material is about matching its inherent strengths to the demands of your environment.

Summary Table:

| Material | Key Strength | Best For |

|---|---|---|

| Natural Rubber | Superior flexibility and all-day comfort | General-purpose wear, long periods of walking |

| PVC (Polyvinyl Chloride) | Excellent chemical, oil, and abrasion resistance | Industrial, agricultural, and processing work |

| Neoprene | Superior thermal insulation | Cold weather work, hunting, fishing |

Need the Right Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial and safety footwear for distributors, brand owners, and bulk clients. Whether your team needs the comfort of natural rubber or the industrial-grade durability of PVC, we have the production capabilities and expertise to deliver.

Contact our team today to discuss your specific requirements and get a customized solution.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What factors should be considered when choosing rain boots? Find the Perfect Boot for Your Needs

- What are the characteristics of rubber as a rain boot material? Discover Its Durability & Flexibility

- What mechanical challenges arise for protective footwear in flood transitions? Ensure Stability in Dynamic Environments

- What alternatives exist for extreme wet conditions beyond waterproof hiking boots? Discover the Best Footwear for Saturated Terrain

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.