When selecting protective footwear, the two primary materials you will encounter are Polyvinyl Chloride (PVC) and rubber. While both are used to create waterproof and durable boots, they possess fundamentally different properties that make them suitable for very different applications and hazards.

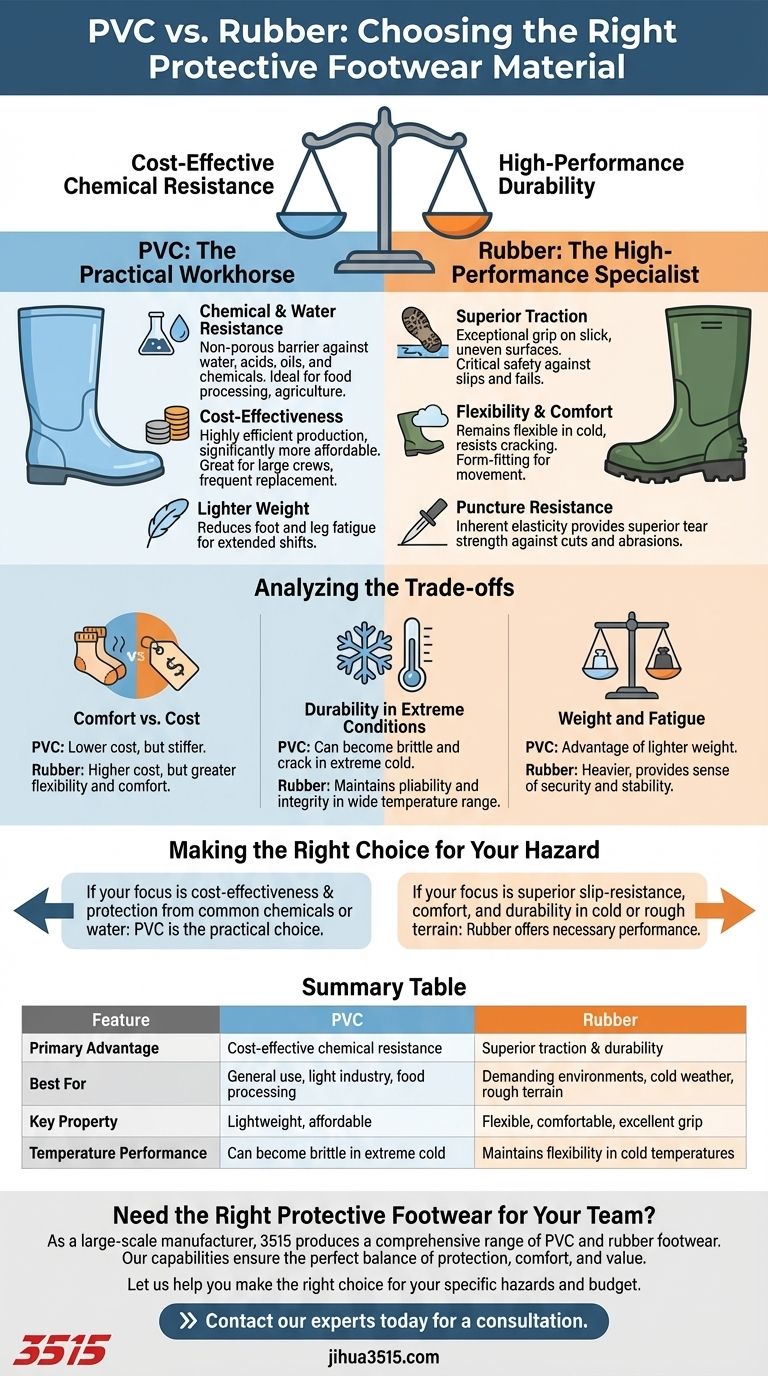

The core decision between PVC and rubber is a trade-off between cost-effective chemical resistance and high-performance durability. PVC offers a practical, lightweight, and affordable solution for general use, while rubber provides superior traction, flexibility, and comfort for more demanding environments.

Understanding PVC: The Practical Workhorse

Polyvinyl Chloride is a synthetic plastic polymer known for its versatility and low production cost. This makes it an extremely common choice for general-purpose protective boots.

Key Advantage: Chemical and Water Resistance

PVC is inherently non-porous, creating an excellent barrier against water, acids, fats, oils, and various other common chemicals. This makes it a reliable choice in food processing, agriculture, and light industrial settings.

Key Advantage: Cost-Effectiveness

The manufacturing process for PVC is highly efficient, making it significantly more affordable than rubber. This is ideal for large crews or in situations where boots are frequently replaced due to contamination.

Notable Characteristic: Lighter Weight

Compared to traditional rubber boots, PVC footwear is generally lighter. This can reduce foot and leg fatigue for workers who are on their feet for extended shifts.

Understanding Rubber: The High-Performance Specialist

Natural or synthetic rubber has been the traditional material for high-quality waterproof boots for decades. It is valued for its natural resilience and protective qualities.

Key Advantage: Superior Traction

Rubber's natural softness and high coefficient of friction provide an exceptional grip on wet, slick, and uneven surfaces. This is a critical safety feature in industries where slips and falls are a primary concern.

Key Advantage: Flexibility and Comfort

Rubber remains flexible even in very cold temperatures, resisting cracks and splits. This pliability allows for a more comfortable, form-fitting boot that moves with the wearer.

Notable Characteristic: Puncture Resistance

The inherent elasticity and tear strength of rubber often give it superior resistance to cuts, punctures, and abrasions when compared to standard PVC.

Analyzing the Trade-offs

Neither material is universally superior; the correct choice depends entirely on the specific hazards and environmental conditions of the job.

Comfort vs. Cost

The most significant trade-off is price versus user comfort. PVC provides essential protection at a lower cost but can feel stiff. Rubber costs more but delivers a substantial increase in flexibility and overall comfort.

Durability in Extreme Conditions

In extreme cold, PVC has a tendency to become brittle and can crack upon impact, compromising its protective barrier. Rubber maintains its pliability and integrity in a much wider temperature range.

Weight and Fatigue

While the lighter weight of PVC is often an advantage, the heavier, more substantial feel of a rubber boot can provide a greater sense of security and stability in rugged terrain.

Making the Right Choice for Your Hazard

Your specific work environment and the primary hazards you face should dictate your choice of material.

- If your primary focus is cost-effectiveness and protection from common chemicals or water: PVC is the most practical and economical choice for general-purpose applications.

- If your primary focus is superior slip-resistance, comfort, and durability in cold or rough terrain: Rubber offers the necessary performance and safety advantages for more demanding jobs.

Understanding these core material differences empowers you to select footwear that provides the right protection for the task at hand.

Summary Table:

| Feature | PVC | Rubber |

|---|---|---|

| Primary Advantage | Cost-effective chemical resistance | Superior traction & durability |

| Best For | General use, light industry, food processing | Demanding environments, cold weather, rough terrain |

| Key Property | Lightweight, affordable | Flexible, comfortable, excellent grip |

| Temperature Performance | Can become brittle in extreme cold | Maintains flexibility in cold temperatures |

Need the Right Protective Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of PVC and rubber footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the perfect balance of protection, comfort, and value.

Let us help you make the right choice for your specific hazards and budget.

Contact our experts today for a consultation to discuss your requirements and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- What are the benefits of lubricating work shoes? Protect Your Investment & Extend Lifespan

- What core protections do industrial-grade safety shoes provide? Safeguarding Gemstone Miners Against Critical Hazards

- What is the importance of wearing safety shoes in the workplace? Protect Your Team and Your Bottom Line

- What technical components of professional footwear are necessary to alleviate lower limb fatigue? Guide to Peak Support

- What is the current safety footwear standard in Europe? Your Guide to EN ISO 20345

- What is the function of a climate simulation chamber for Safety Shoes? Enhancing Physiological Performance and Safety

- What protective functions do industrial safety shoes provide in second-hand recycling? Safeguard Your Sorting Teams

- How do safety shoes provide electrical hazard protection? Essential Insights for Workplace Safety