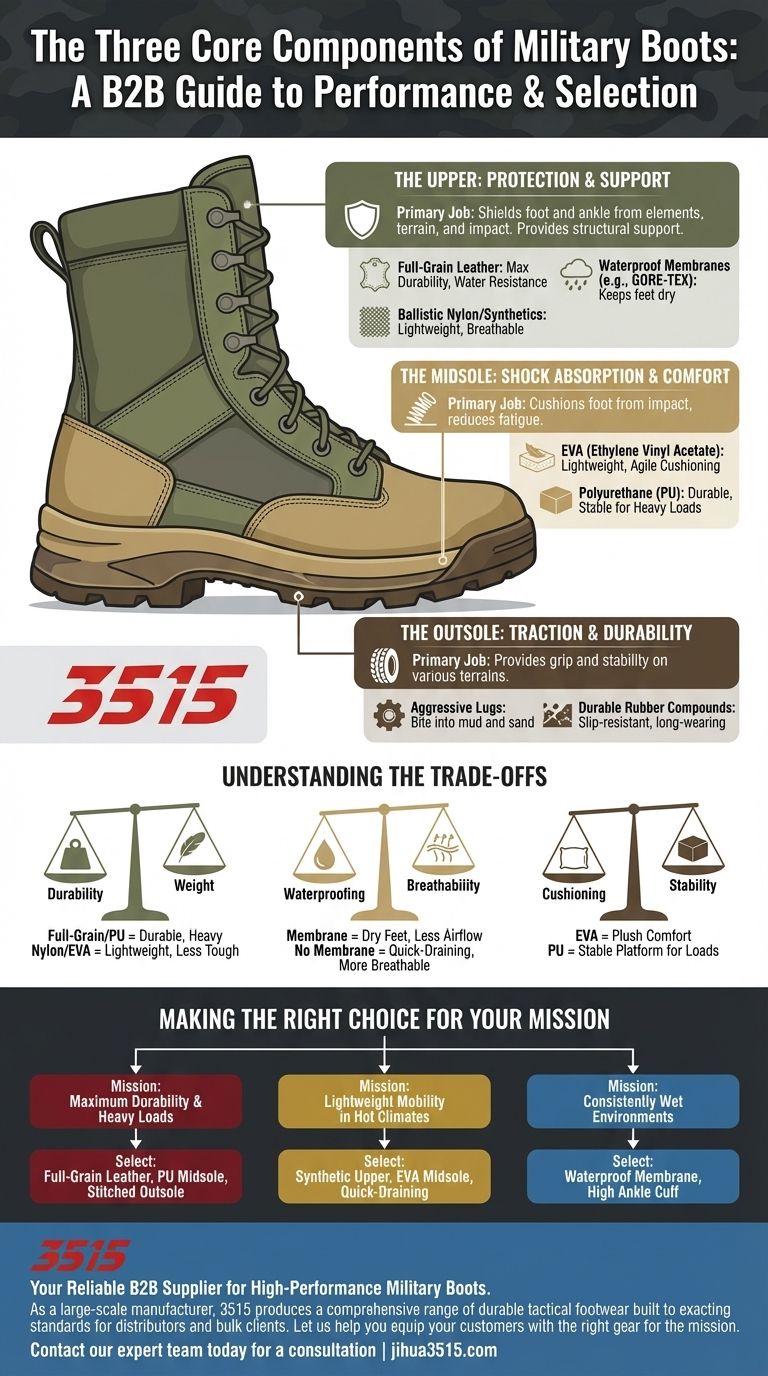

At a fundamental level, every military boot is constructed from three core components that form a complete system for your foot. These are the Upper, which protects the foot and ankle; the Midsole, which provides cushioning and absorbs shock; and the Outsole, which makes contact with the ground to provide traction. Together, these elements dictate the boot's performance, durability, and suitability for a given environment.

Understanding the function of each component is more important than just knowing their names. The specific materials and design of the upper, midsole, and outsole determine whether a boot is built for arid deserts, wet jungles, or heavy load-bearing marches.

The Upper: Your First Line of Defense

The upper is the entire part of the boot that covers your foot and ankle. Its primary job is to provide protection from the elements, terrain, and impact while offering structural support.

Core Function and Protection

The upper shields your foot from water, debris, and abrasion. Its height provides crucial ankle support, which is essential when navigating uneven ground or carrying heavy loads.

Key Materials Define Performance

The materials used here create a significant trade-off between durability and breathability. Full-grain leather offers maximum durability and water resistance but can be heavy and hot. Ballistic nylon and other synthetics are much lighter and more breathable but may offer less resistance to abrasion.

The Role of Linings and Membranes

Modern boots often include inner layers within the upper. A waterproof membrane (like GORE-TEX) is a common addition to keep feet dry from external moisture, while moisture-wicking linings help manage sweat from the inside.

The Midsole: The Unseen Shock Absorber

Sandwiched between your foot and the outsole, the midsole is the boot's engine for comfort and support. Its role is to cushion your foot from repeated impact, reducing fatigue over long distances.

Absorbing Impact

Every step you take generates force that travels up your legs and spine. The midsole's primary function is to absorb and dissipate that shock.

Common Cushioning Materials

Two materials dominate midsole construction: EVA (ethylene vinyl acetate) foam is lightweight and offers excellent cushioning, making it feel comfortable and agile. Polyurethane (PU) is a denser, heavier foam that is more durable and provides superior stability, making it ideal for boots designed to carry heavy loads.

The Outsole: Where Rubber Meets the Road

The outsole is the bottom-most layer of the boot that directly contacts the ground. Its design is entirely focused on providing traction, stability, and durability.

Traction and Grip

The outsole's performance is defined by its tread pattern. Deep, aggressive lugs are designed to bite into soft terrain like mud and sand, while multi-directional patterns ensure reliable grip during ascents, descents, and lateral movements.

Material and Construction

Outsoles are almost always made of durable rubber compounds. Some are formulated to be slip-resistant on wet surfaces, while others are harder to better resist wear on rock and pavement. They are typically glued and often stitched to the upper for maximum durability.

Understanding the Trade-offs

Choosing the right military boot involves balancing competing characteristics. There is no single "best" boot, only the best boot for a specific purpose.

Durability vs. Weight

A boot made entirely of thick, full-grain leather with a dense PU midsole will last for years but will also be heavy. A lighter boot with extensive nylon panels and an EVA midsole will be far more comfortable on a quick march but won't stand up to the same level of abuse.

Waterproofing vs. Breathability

A waterproof membrane is excellent for keeping your feet dry in rain or when crossing shallow streams. However, that same membrane traps heat and sweat, making the boot less comfortable in hot, dry climates. Furthermore, if a waterproof boot is fully submerged, it will take significantly longer to dry out than a non-waterproof, quick-draining boot.

Cushioning vs. Stability

A soft, highly cushioned EVA midsole can feel incredibly comfortable but may compress over time and offer less stability when carrying a heavy pack. A firmer PU midsole provides a more stable platform for load-bearing but offers less initial "plush" comfort.

Making the Right Choice for Your Mission

By understanding how these components function, you can analyze a boot's design to see if it aligns with your needs.

- If your primary focus is maximum durability and load-bearing: Seek a boot with a predominantly full-grain leather upper, a dense polyurethane (PU) midsole, and a stitched outsole.

- If your primary focus is lightweight mobility in hot climates: Prioritize boots with synthetic uppers (like nylon or mesh), quick-draining ports, and a lighter EVA midsole.

- If your primary focus is operating in consistently wet environments: A boot with a reliable waterproof membrane and a high ankle cuff is critical to keep water from getting in.

Understanding how these core components work as a system empowers you to choose a specialized tool, not just a piece of footwear.

Summary Table:

| Component | Primary Function | Key Materials & Features |

|---|---|---|

| Upper | Protection & Support | Full-grain leather, ballistic nylon, GORE-TEX membrane |

| Midsole | Cushioning & Shock Absorption | EVA (lightweight), Polyurethane/PU (durable & stable) |

| Outsole | Traction & Durability | Durable rubber compounds with aggressive lug patterns |

Need a Reliable Supplier for High-Performance Military Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear built to exacting standards for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of tactical boots and shoes, ensuring you get the right balance of durability, comfort, and performance for your specific market needs.

Let us help you equip your customers with the right gear for the mission.

Contact our expert team today for a consultation

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What are some maintenance tips for military camouflage boots? Keep Your Gear Field-Ready

- How do the heights of combat boots and jump boots differ? A Guide to Purpose-Built Footwear

- What color shoes go with camouflage? A Guide to Perfect Pairings for Every Style

- How often should military boots be maintained? A Proactive Guide to Maximize Boot Lifespan

- How should military boots fit? Master the Performance Fit for Endurance and Safety

- What are some limitations of combat boots? Heavy, Stiff, and Poorly Ventilated

- What are the defining features of Combat Boots? Unmatched Durability & Protection for Demanding Environments

- How do military camouflage boots enhance performance? Uncover the Secret to Superior Tactical Footwear