For Goodyear welted shoes, the correct specifications are dictated by the shoe's intended use, balancing durability with aesthetics. For heavy work boots with through stitching, use a Size 43 needle, Size 45 awl, and 9s Coretex 4M needle thread. For medium to heavy shoes without through stitching, use a Size 45 needle, Size 47 awl, and 6s Coretex 5M needle thread. For lighter or women’s shoes, a Size 47 needle, Size 50 awl, and 6s Coretex 5M needle thread is recommended.

Selecting the right needle, awl, and thread is not just about following a chart; it's about understanding the physics of a stitch. The goal is to create a secure, durable seam that complements the shoe's design without compromising the integrity of the leather.

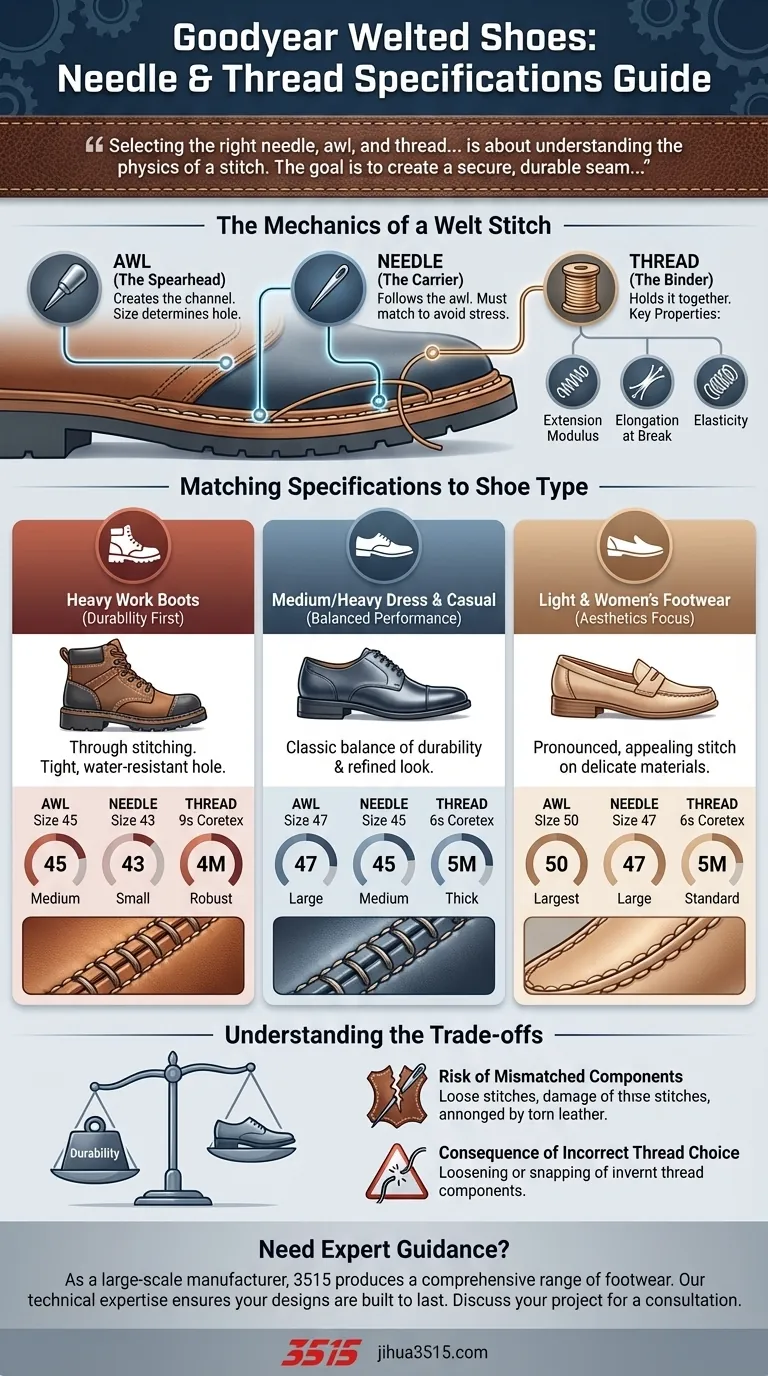

The Mechanics of a Welt Stitch

The strength and appearance of a Goodyear welt seam depend on the precise interplay between the awl, the needle, and the thread. Each component has a specific job, and they must work together as a system.

The Role of the Awl

The awl is the spearhead. Its primary function is to pierce the materials—the welt, the upper, and the insole rib—creating a channel for the needle and thread.

The size of the awl determines the size of the hole. It must be large enough to allow the needle and thread to pass through without excessive friction or damage.

The Function of the Needle

The needle follows the awl, carrying the thread through the pre-made channel. Its size must be carefully matched to both the awl and the thread.

A needle that is too large for the awl's hole will stress the leather. A needle that is too small can lead to poor stitch control and an inconsistent seam.

The Critical Properties of the Thread

The thread is the element that holds everything together. Its physical properties are paramount to the longevity of the shoe.

Key characteristics include:

- Extension Modulus: The thread's resistance to stretching under load, which ensures a tight, secure stitch.

- Elongation at Break: How much the thread can stretch before it snaps, which contributes to seam durability under stress.

- Elasticity: The thread's ability to return to its original length after being stretched, preventing seams from loosening over time.

Matching Specifications to Shoe Type

The specific combination of components changes based on the demands placed on the final product.

For Heavy Work Boots

These shoes prioritize durability above all else. They often feature through stitching, where the outsole is stitched directly through the midsole and welt.

The recommended setup (Needle 43, Awl 45, Thread 9s) uses a relatively smaller needle and awl. This creates a tighter, more water-resistant stitch hole, which is critical for work environments. The robust thread ensures maximum strength.

For Medium & Heavy Dress or Casual Shoes

This category represents the classic Goodyear welted shoe, where a balance of durability and refined appearance is key.

The larger needle (45) and awl (47) combined with a thicker thread (6s) create a strong and visually substantial welt seam. This construction is highly durable for daily wear without the industrial focus of a work boot.

For Light & Women's Footwear

On lighter footwear, the aesthetic qualities of the stitch are often more prominent. Finer leathers and more delicate designs require a different approach.

Using a larger awl (50) and needle (47) can create a more pronounced, intentionally visible stitch. While seemingly oversized, this combination, when used with appropriate tension, can form a beautiful seam without placing undue stress on more delicate upper materials.

Understanding the Trade-offs

Choosing your specifications involves balancing competing factors. There is no single "best" setup, only the most appropriate one for a specific goal.

Durability vs. Aesthetics

A thicker thread and larger stitch create undeniable strength but result in a more rugged, visible seam. A finer thread and needle can produce a sleeker look that may be more appropriate for a formal dress shoe, but with a slight compromise in raw tensile strength.

The Risk of Mismatched Components

Using an awl that is too large for the needle and thread will result in loose, weak stitches that can shift over time. Conversely, forcing a large needle and thread through a hole made by a small awl will damage the thread, break needles, and can tear the leather.

The Consequence of Incorrect Thread Choice

A thread with too much elasticity will result in seams that loosen with wear, compromising the shoe's structure. A thread with too little elasticity might be strong, but it can snap under the sudden shock and shear forces of walking.

Making the Right Choice for Your Goal

Your selection of needle, awl, and thread should be a direct reflection of the shoe you intend to create.

- If your primary focus is maximum durability for workwear: Opt for the tighter stitch hole and robust thread specified for heavy-duty construction.

- If your primary focus is a classic, long-lasting dress or casual shoe: Use the balanced, mid-range specifications to achieve both strength and a clean aesthetic.

- If your primary focus is a refined look on lightweight footwear: Employ the specifications for lighter shoes, paying close attention to tension to create a visually appealing stitch on delicate materials.

Mastering these technical specifications is fundamental to controlling the final quality and character of your footwear.

Summary Table:

| Shoe Type | Needle Size | Awl Size | Thread Specification |

|---|---|---|---|

| Heavy Work Boots (with through stitching) | 43 | 45 | 9s Coretex 4M |

| Medium/Heavy Dress & Casual Shoes | 45 | 47 | 6s Coretex 5M |

| Light & Women's Footwear | 47 | 50 | 6s Coretex 5M |

Need expert guidance on materials for your next footwear line? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and our technical expertise ensures your designs are built to last with the right construction details. Let's discuss your project – contact our team today for a consultation.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What are the advantages and disadvantages of leather as a shoe material? Unlock Durability, Comfort & Style

- How should new leather work boots be broken in? A Guide to Comfort and Durability

- What is the complete process for deep cleaning leather work boots? A Step-by-Step Guide to Preserve Your Investment

- How can the flexibility of leather work boots be maximized? Achieve Lasting Comfort & Performance

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection