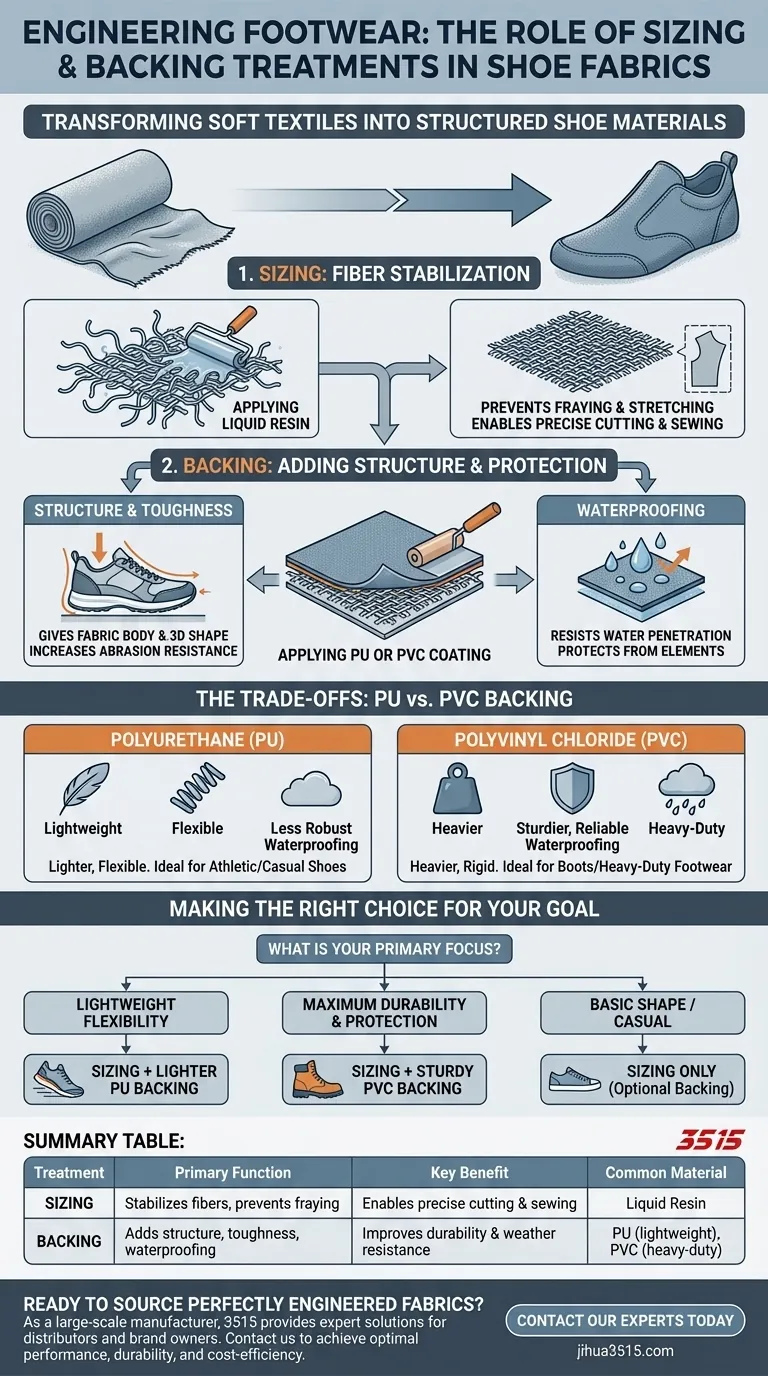

In footwear manufacturing, sizing and backing are essential treatments used to transform soft, shapeless textiles into materials suitable for shoes. Sizing involves applying a liquid resin to stabilize the fabric's fibers, while backing adds a coating like polyurethane (PU) or polyvinyl chloride (PVC) to impart toughness, structure, and waterproofing.

The core purpose of these treatments is to give standard fabric the necessary structural integrity and durability required for shoemaking. Without them, most textiles would be too flimsy to cut, shape, and withstand the demands of daily wear.

The Role of Sizing: From Fabric to Stable Material

Sizing is the foundational step in preparing a textile for footwear production. It addresses the inherent instability of woven or knit materials.

What is Sizing?

Sizing is the process of applying a liquid resin to the fabric. This resin permeates the material and bonds the individual fibers together.

The Goal: Fiber Stabilization

The primary function of sizing is to prevent the fabric from stretching, fraying, or distorting. It effectively turns a pliable textile into a more rigid, workable sheet.

Impact on Manufacturing

This stability is critical for the cutting and sewing stages. A sized fabric can be cut into precise pattern pieces without unraveling and holds its shape during stitching, ensuring a consistent and well-constructed final product.

The Role of Backing: Adding Strength and Protection

While sizing provides stability, backing adds the bulk, resilience, and environmental resistance needed for a shoe's upper.

What is Backing?

Backing involves applying a solid coating to the reverse side of the fabric. Common materials include PU and PVC, each offering different properties.

The Goal: Structure and Toughness

This added layer gives the fabric "body" and helps the shoe hold its three-dimensional shape. It also significantly increases abrasion resistance, protecting the fabric from scuffs and wear.

A Key Function: Waterproofing

A crucial benefit of backing is its ability to make the fabric resistant to water. This protects the wearer's foot from the elements and prevents the shoe from becoming waterlogged.

Understanding the Trade-offs: PU vs. PVC Backing

The choice between different backing materials involves a direct trade-off between weight and protection.

Polyurethane (PU) Backing

PU coatings are generally lighter and more flexible. This makes them a good choice for athletic or casual shoes where minimizing weight is a priority.

However, the waterproofing provided by PU is typically less robust compared to other options.

Polyvinyl Chloride (PVC) Backing

PVC is a heavier and more rigid material. It provides sturdier, more reliable waterproofing.

This makes PVC backing ideal for boots or heavy-duty footwear designed to withstand harsh weather conditions and rough use.

Making the Right Choice for Your Goal

The combination of sizing and backing must be selected based on the specific performance requirements of the footwear.

- If your primary focus is lightweight flexibility: A standard sizing treatment paired with a lighter PU backing will deliver structure without adding excess weight.

- If your primary focus is maximum durability and weather protection: Sizing combined with a sturdy PVC backing will provide the most robust defense against abrasion and moisture.

- If your primary focus is basic shape for a casual shoe: A simple sizing treatment may suffice on its own, with backing added only where extra resilience is required.

Ultimately, these treatments are the critical engineering steps that elevate a simple fabric into a high-performance footwear material.

Summary Table:

| Treatment | Primary Function | Key Benefit | Common Material |

|---|---|---|---|

| Sizing | Stabilizes fibers, prevents fraying | Enables precise cutting & sewing | Liquid Resin |

| Backing | Adds structure, toughness, waterproofing | Improves durability & weather resistance | PU (lightweight), PVC (heavy-duty) |

Ready to source perfectly engineered fabrics for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise ensures you get the right combination of sizing and backing treatments—whether you need lightweight PU for athletic shoes or rugged PVC for work boots—to achieve optimal performance, durability, and cost-efficiency.

Contact our experts today to discuss your specific fabric needs and get a quote.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

People Also Ask

- What are the advantages of rubber soles in sneakers? Unmatched Grip, Durability & Comfort

- How do rubber and TPR soles compare in terms of water resistance? A Guide to Grip and Performance

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality