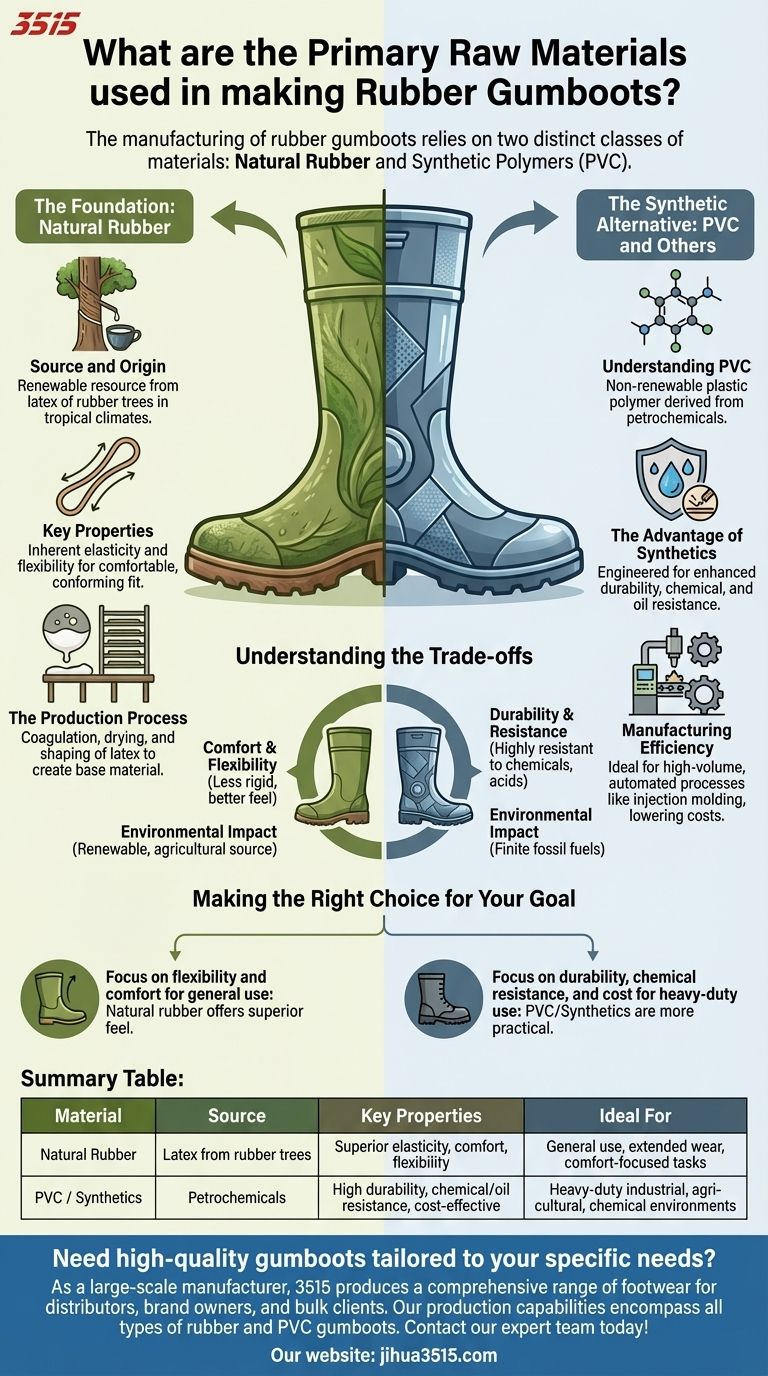

At its core, the manufacturing of rubber gumboots relies on two distinct classes of materials. The primary raw materials are natural rubber, which is harvested from the latex of rubber trees, and synthetic polymers, most notably polyvinyl chloride (PVC) and other synthetic rubbers derived from petrochemicals.

The fundamental choice in gumboot construction is a trade-off: the natural flexibility of traditional rubber versus the specialized durability and cost-efficiency of modern synthetic compounds.

The Foundation: Natural Rubber

Source and Origin

Natural rubber is a renewable resource. It is derived directly from the milky white sap, known as latex, which is tapped from rubber trees predominantly grown in tropical climates like those in Thailand and Indonesia.

Key Properties

The defining characteristic of natural rubber is its inherent elasticity and flexibility. This allows for a comfortable fit that can conform to the wearer's foot, making it ideal for extended use.

The Production Process

Once the latex is collected, it undergoes a series of processing steps. These include coagulation, where the liquid latex is solidified, followed by drying and shaping to create the base material for the boots.

The Synthetic Alternative: PVC and Others

Understanding PVC

Polyvinyl chloride (PVC), also known as vinyl, is a widely used synthetic plastic polymer. Unlike natural rubber, its origin is in petrochemicals, making it a non-renewable but highly versatile material.

The Advantage of Synthetics

Synthetic materials like PVC or other synthetic rubbers are engineered for specific performance traits. They are often formulated to enhance durability, flexibility, and resistance to degradation from chemicals, oils, and abrasion.

Manufacturing Efficiency

Synthetic polymers are exceptionally well-suited for high-volume, automated manufacturing processes like injection molding. This efficiency often translates into a more consistent final product and a lower overall cost.

Understanding the Trade-offs

Performance and Comfort

Natural rubber typically offers superior comfort and flexibility, feeling less rigid during movement. PVC boots, while completely waterproof, can be stiffer but provide excellent protection.

Durability and Resistance

For industrial or agricultural settings, synthetics often have an edge. PVC is highly resistant to a wide range of chemicals and acids that can degrade natural rubber over time.

Environmental Impact

The choice of material has significant environmental implications. Natural rubber comes from a renewable, agricultural source, whereas PVC and other synthetic rubbers are derived from finite fossil fuels.

Making the Right Choice for Your Goal

Selecting the right gumboot depends entirely on its intended application.

- If your primary focus is flexibility and comfort for general use: Natural rubber gumboots offer a superior feel and classic performance.

- If your primary focus is durability, chemical resistance, and cost for heavy-duty use: PVC or other synthetic gumboots are the more practical and resilient choice.

Ultimately, understanding the material's origin and properties is the key to selecting a gumboot that truly serves its intended purpose.

Summary Table:

| Material | Source | Key Properties | Ideal For |

|---|---|---|---|

| Natural Rubber | Latex from rubber trees | Superior elasticity, comfort, flexibility | General use, extended wear, comfort-focused tasks |

| PVC / Synthetics | Petrochemicals | High durability, chemical/oil resistance, cost-effective | Heavy-duty industrial, agricultural, chemical environments |

Need high-quality gumboots tailored to your specific needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of rubber and PVC gumboots, ensuring you get the perfect balance of comfort, durability, and value.

Contact our expert team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What are the main materials used in the construction of half-boots? A Guide to Durability & Performance

- What options are available for men's gardening boots? Find the Perfect Fit for Your Garden's Needs

- What are the benefits of natural rubber in Wellington boots? Superior Comfort, Durability & Grip

- What is the overall recommendation for choosing rain boot materials? A Guide to Rubber vs. PVC

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability

- How should waterproof shoes be washed? Protect Your Investment with Proper Care

- How is the steel head incorporated into PVC rain boots? A Guide to Insert Molding for Safety

- What should you check to ensure wellies keep feet warm and dry? A Guide to Dry, Warm Feet