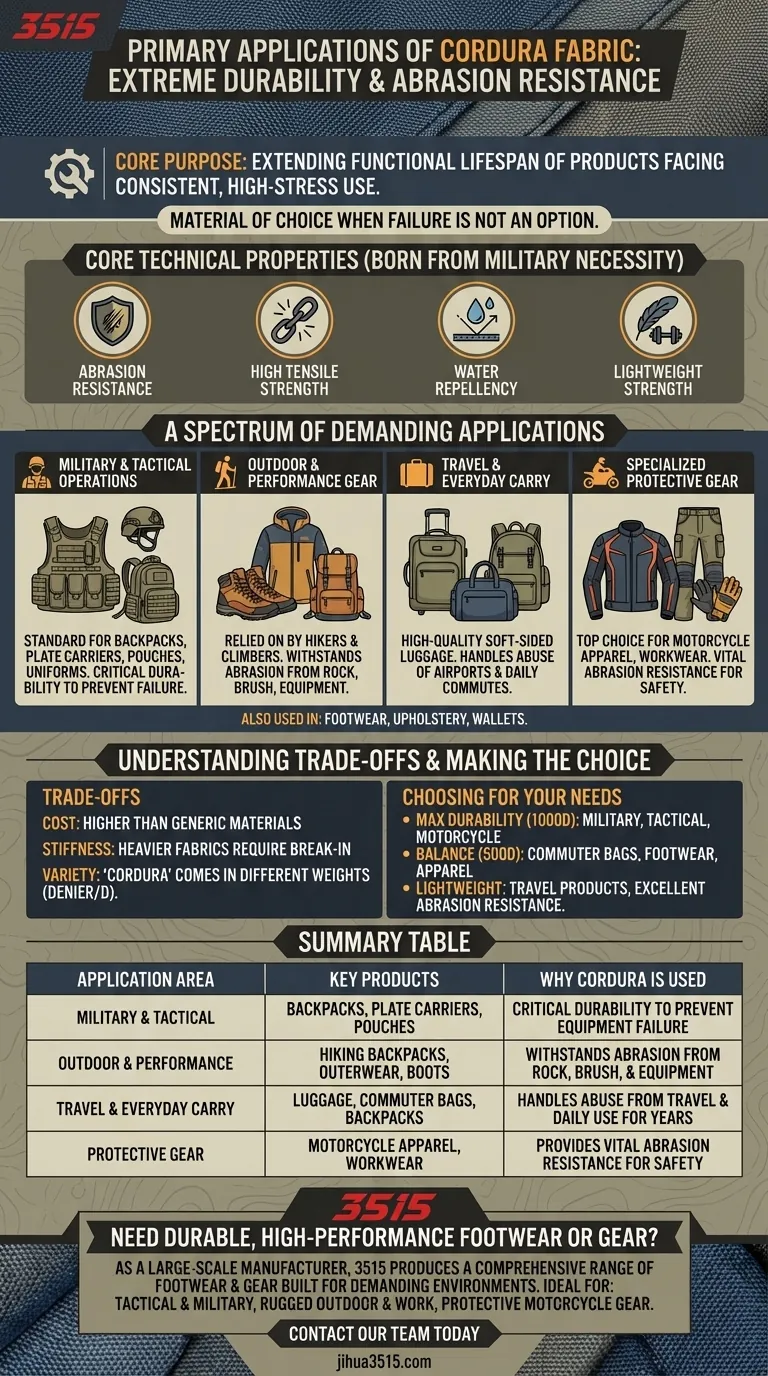

Cordura fabric is primarily used in applications where extreme durability and abrasion resistance are non-negotiable. Its most common applications span military and tactical gear, high-performance outdoor equipment, rugged luggage, and protective apparel for activities like motorcycling. At its core, Cordura is engineered to extend the functional lifespan of products that face consistent, high-stress use.

While Cordura is found in everything from backpacks to footwear, its true purpose isn't the product itself, but the extension of that product's life. It is the material of choice when failure due to wear and tear is simply not an option.

The Foundation: From Military Roots to Modern Gear

To understand why Cordura is so widely used, it’s essential to look at its core properties, which were born from military necessity.

A Legacy of Toughness

Originally developed by DuPont for military tires during World War II, Cordura's heritage is rooted in creating materials that could withstand the harshest possible conditions. This military-grade toughness remains its defining characteristic.

Core Technical Properties

The specific applications of Cordura are a direct result of its technical makeup. It is not just one fabric, but a family of fabrics built on high-tenacity nylon 6,6 fiber technology.

- Abrasion Resistance: Cordura's primary strength is its exceptional ability to resist scrapes, scuffs, and friction without tearing.

- High Tensile Strength: The fibers are incredibly strong under tension, preventing rips and punctures even under significant load.

- Water Repellency: Most Cordura fabrics are treated with a coating (often polyurethane) and a water-repellent finish, causing water to bead up and roll off.

- Lightweight Strength: Despite its toughness, Cordura provides a very high strength-to-weight ratio compared to traditional materials like canvas.

A Spectrum of Demanding Applications

Cordura's versatility allows it to be engineered into different weights and textures, making it suitable for a wide range of products where durability is paramount.

Military and Tactical Operations

This is Cordura's flagship application. It is the standard for military-grade backpacks, plate carriers, pouches, and uniforms where equipment failure can have critical consequences.

Outdoor and Performance Gear

Hikers, climbers, and adventurers rely on Cordura for backpacks, outerwear, and boots. The material must withstand constant rubbing against rock, brush, and other equipment without failing.

Travel and Everyday Carry

For consumers, Cordura is most commonly found in high-quality soft-sided luggage, travel bags, and daily-use backpacks. Its durability ensures the product can handle the abuse of airports and daily commutes for years.

Specialized Protective Gear

The fabric is a top choice for motorcycle apparel, including jackets and pants, where its abrasion resistance provides a vital layer of protection in a crash. It is also used in workwear for professionals in demanding trades.

Beyond Apparel and Bags

Cordura's utility extends to items like durable footwear, long-lasting furniture upholstery, and even wallets, proving its adaptability to almost any product that needs to last.

Understanding the Trade-offs

While highly effective, Cordura is a specialized material, and choosing it involves understanding its limitations.

The Cost Factor

Products made with genuine Cordura fabric are typically more expensive than those made with generic polyester or standard nylon. This cost reflects the advanced fiber technology and rigorous quality standards.

Stiffness and Break-in Period

Heavier-duty Cordura fabrics (like 1000D) can feel stiff and rigid when new. They often require a "break-in" period to become more pliable and comfortable, particularly in apparel.

Not All Cordura is Equal

"Cordura" is a brand, not a single material. It comes in many different weights, measured in denier (D). A 500D Cordura used for a daypack is very different from the much heavier and more abrasion-resistant 1000D Cordura used on a military pack. Misunderstanding this can lead to choosing the wrong product for the task.

Making the Right Choice for Your Needs

Selecting a product with Cordura means prioritizing long-term performance. Your specific goal will determine which type of Cordura fabric is most appropriate.

- If your primary focus is maximum durability for critical gear: Seek out products using high-denier Cordura (e.g., 1000D) for military, tactical, or motorcycle applications.

- If your primary focus is a balance of toughness and daily comfort: Look for Cordura blends or mid-weight versions (e.g., 500D) in commuter backpacks, footwear, or everyday apparel.

- If your primary focus is lightweight travel: Opt for products made with lower-denier Cordura fabrics that provide excellent abrasion resistance without excessive bulk.

Ultimately, choosing Cordura is an investment in a product's longevity and its ability to perform reliably under pressure.

Summary Table:

| Application Area | Key Products | Why Cordura is Used |

|---|---|---|

| Military & Tactical | Backpacks, Plate Carriers, Pouches | Critical durability to prevent equipment failure |

| Outdoor & Performance | Hiking Backpacks, Outerwear, Boots | Withstands abrasion from rock, brush, and equipment |

| Travel & Everyday Carry | Luggage, Commuter Bags, Backpacks | Handles abuse from travel and daily use for years |

| Protective Gear | Motorcycle Apparel, Workwear | Provides vital abrasion resistance for safety |

Need Durable, High-Performance Footwear or Gear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear and gear built for demanding environments. Whether you are a distributor, brand owner, or bulk client, we leverage durable materials and advanced manufacturing to ensure your products deliver exceptional longevity and performance.

Our production capabilities encompass all types of shoes and boots, ideal for:

- Tactical & Military Applications

- Rugged Outdoor & Work Footwear

- Protective Motorcycle Gear

Partner with us to create products that withstand extreme use.

Contact our team today to discuss your manufacturing needs and how we can bring durability and reliability to your product line.

Visual Guide

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

People Also Ask

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- What regular maintenance checks should be performed on safety boots? A Daily Safety Checklist

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health

- What is ASTM International and what does it do? A Guide to Global Standards

- Why is maintenance important for work boots? Protect Your Investment and Safety