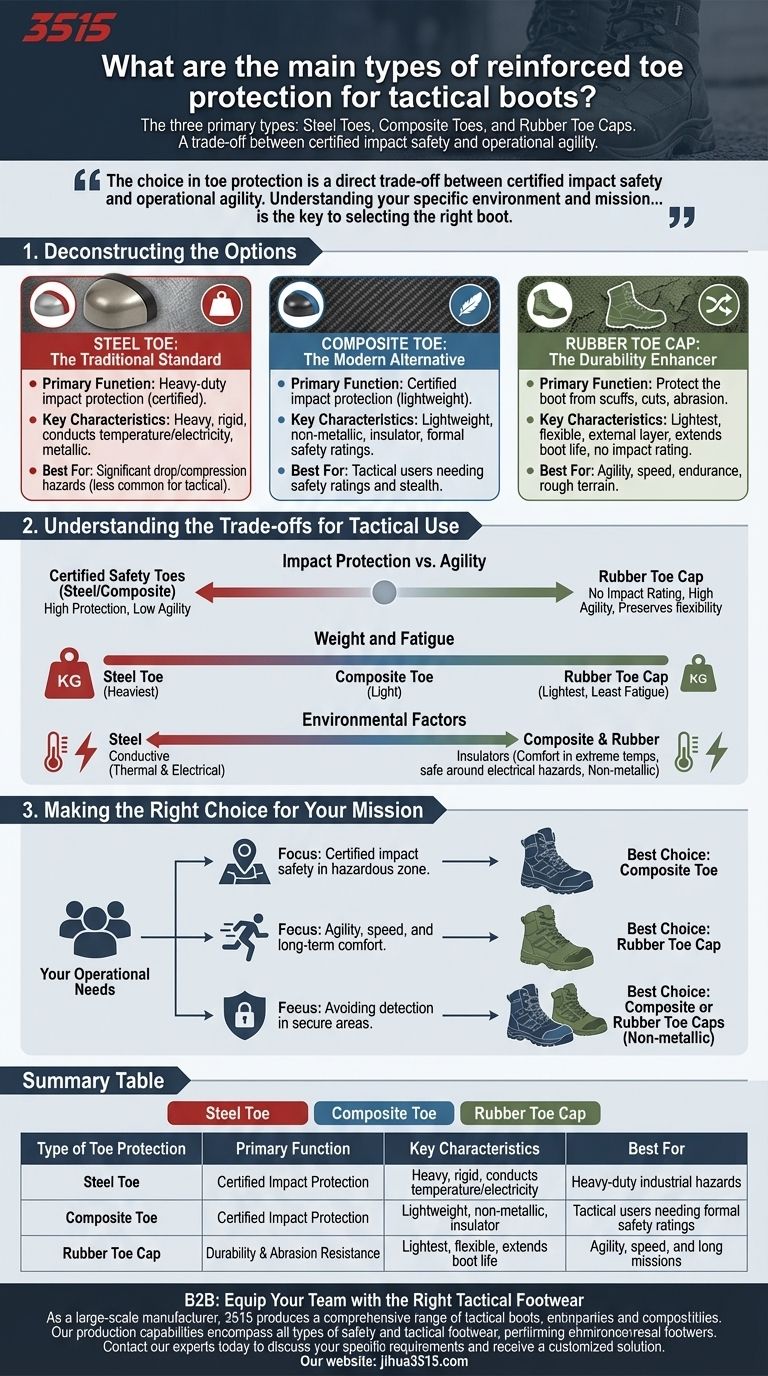

To be clear, the three primary types of reinforced toe protection you will find on boots are steel toes, composite toes, and rubber toe caps. While steel and composite toes provide certified impact protection, rubber toe caps focus on enhancing durability and abrasion resistance, making them a common feature in tactical footwear where agility is paramount.

The choice in toe protection is a direct trade-off between certified impact safety and operational agility. Understanding your specific environment and mission—whether it involves drop hazards or the need for speed and endurance—is the key to selecting the right boot.

Deconstructing the Options

Each type of reinforcement serves a distinct purpose, defined by its material properties and intended use case. What protects a construction worker is not necessarily what best serves a law enforcement officer or soldier.

Steel Toe: The Traditional Standard

Steel toes are the classic solution for heavy-duty impact protection. They are designed to meet stringent safety standards for workplaces with significant drop and compression hazards, like construction sites.

However, their weight, thermal conductivity (they get very cold or hot), and metallic nature make them a poor fit for most tactical applications where mobility and stealth are critical.

Composite Toe: The Modern Alternative

Composite toes offer a modern, lightweight alternative to steel. Made from materials like carbon fiber, plastic, or Kevlar, they provide certified impact protection without the associated weight penalty.

They are also non-metallic, meaning they won't set off metal detectors or conduct electricity. This makes them a viable choice for tactical users who require formal safety ratings in specific operational environments.

Rubber Toe Cap: The Durability Enhancer

This is the most common form of toe reinforcement found on tactical boots. A rubber or synthetic cap is an external layer bonded over the front of the boot.

Its primary function is not to protect your foot from impact, but to protect the boot itself from scuffs, cuts, and abrasion. This drastically increases the service life of the footwear, especially for users who are frequently kneeling, climbing, or moving through rough terrain.

Understanding the Trade-offs for Tactical Use

In tactical scenarios, every ounce of weight and every degree of flexibility matters. The choice of toe protection must be weighed against its impact on your overall effectiveness.

Impact Protection vs. Agility

The core trade-off is simple: certified safety toes (steel, composite) protect against heavy impacts but add weight and rigidity, potentially slowing you down.

A rubber toe cap offers no formal impact rating. Instead, it preserves the boot's natural flexibility and light weight, enhancing agility while protecting your investment from wear and tear.

Weight and Fatigue

Over a long patrol, the extra weight of a safety toe can lead to significant fatigue. Steel is the heaviest offender.

Composite toes are much lighter than steel, but a simple rubber cap adds the least amount of weight, making it the superior choice for missions that demand endurance.

Environmental Factors

Steel's thermal and electrical conductivity can be a liability. In contrast, composite toes are insulators, making them far more comfortable in extreme temperatures and safer around electrical hazards.

Rubber toe caps are environmentally neutral, simply adding a layer of rugged durability to the boot's exterior.

Making the Right Choice for Your Mission

Your operational needs should be the sole determining factor in your choice.

- If your primary focus is certified impact safety in a known hazardous zone: A composite toe offers the best combination of protection and performance for tactical use.

- If your primary focus is agility, speed, and long-term comfort: A boot with a reinforced rubber toe cap provides crucial durability against abrasion without compromising mobility.

- If your primary focus is avoiding detection in secure areas: Composite or rubber toe caps are essential non-metallic options.

Ultimately, selecting the correct toe protection is about aligning the boot's features with the demands of your environment.

Summary Table:

| Type of Toe Protection | Primary Function | Key Characteristics | Best For |

|---|---|---|---|

| Steel Toe | Certified Impact Protection | Heavy, rigid, conducts temperature/electricity | Heavy-duty industrial hazards (less common for tactical) |

| Composite Toe | Certified Impact Protection | Lightweight, non-metallic, insulator | Tactical users needing formal safety ratings |

| Rubber Toe Cap | Durability & Abrasion Resistance | Lightest, flexible, extends boot life | Agility, speed, and long missions where durability is key |

Equip Your Team with the Right Tactical Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of tactical boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and tactical footwear, ensuring you get the perfect balance of protection, durability, and performance for any mission profile.

Contact our experts today to discuss your specific requirements and receive a customized solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture