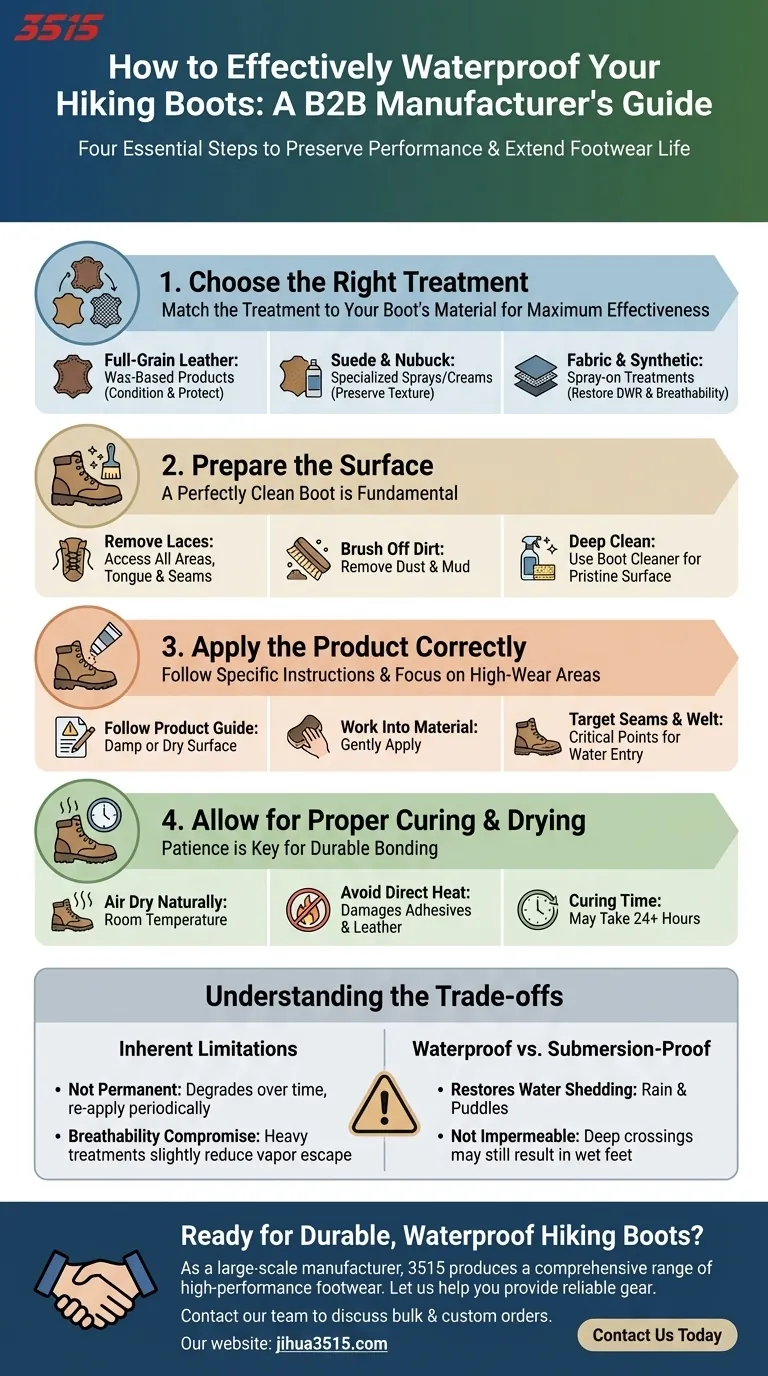

To effectively waterproof your hiking boots, the process involves four primary steps: choosing the correct treatment for your boot's material, thoroughly cleaning the boots, applying the treatment, and allowing the boots to dry completely. This routine maintenance not only keeps your feet dry but is critical for extending the functional life of your footwear.

The success of any waterproofing effort depends less on the application itself and more on the preparation. Applying the right product to a perfectly clean boot is the fundamental principle that ensures a durable, water-resistant barrier.

The Foundation: Why Re-Waterproofing is Essential

Before diving into the process, it's important to understand why this maintenance is not optional for serious hikers. Factory-applied treatments, often a Durable Water Repellent (DWR) coating, wear off with use.

Protecting Your Feet from Moisture

The most immediate benefit is keeping your feet dry in rain, snow, or on wet trails. Dry feet are crucial for comfort, maintaining warmth, and significantly reducing the risk of blisters caused by friction on damp skin.

Extending the Lifespan of Your Boots

Water can be incredibly damaging to boot materials, especially leather. Regular waterproofing prevents leather from drying out, cracking, and deteriorating, preserving the boot's structural integrity and support for much longer.

Step-by-Step Guide to Effective Application

Follow these steps precisely. Skipping or rushing any stage will compromise the result and waste both product and effort.

Step 1: Choose the Right Waterproofing Treatment

This is the most critical decision. The treatment must match your boot's primary material to be effective.

- For full-grain leather boots, wax-based products are often the best choice. They provide a robust barrier and condition the leather.

- For suede or nubuck leather, use specialized sprays or creams. These are designed to provide water resistance without matting down the textured surface.

- For fabric and synthetic boots, a spray-on treatment is ideal. These are formulated to restore the DWR coating without affecting breathability.

Step 2: Prepare the Surface for Treatment

You cannot apply waterproofing to a dirty boot. The treatment will bond to the dirt, not the boot material, and will fail almost immediately.

First, remove the laces to ensure you can access the entire boot, including the tongue and all seams.

Next, use a soft boot brush to remove all loose dust, mud, and debris. Pay close attention to the seams and welt where dirt collects.

Finally, for a deep clean, use a specialized boot cleaner and a small amount of water. This removes ingrained grime and old, failed treatments, providing a pristine surface for the new application.

Step 3: Apply the Product Correctly

Follow the specific instructions on your chosen waterproofing product. Some treatments are designed to be applied to damp boots, while others require a completely dry surface.

Gently work the product into the material, paying special attention to high-wear areas and seams, which are the most common points of failure for water entry.

Step 4: Allow for Proper Curing and Drying

Patience is key. After application, let your boots air dry naturally at room temperature, away from direct heat sources like fires or radiators.

Excessive heat can damage adhesives and cause leather to crack, permanently harming your boots. The treatment needs time to cure and bond properly, which can take 24 hours or more.

Understanding the Inevitable Trade-offs

Re-waterproofing is a powerful maintenance tool, but it's important to have realistic expectations about its limitations.

No Treatment Lasts Forever

Waterproofing is not a permanent solution. It is a protective layer that degrades over time due to abrasion, flexing, and exposure. You will need to re-apply it periodically, especially after heavy use in wet conditions.

The Breathability Compromise

A boot's ability to let sweat vapor escape is known as breathability. Heavier waterproofing treatments, particularly wax-based products, can slightly reduce a boot's breathability. This is a trade-off between maximum water resistance and interior moisture management.

Waterproof vs. Submersion-Proof

Re-waterproofing restores your boots' ability to shed water from rain and puddles. It does not make them impermeable like rubber boots. Deep stream crossings or full submersion will likely still result in wet feet, often through the tongue junction or the top of the boot.

Making the Right Choice for Your Boots

Your boot's material dictates your waterproofing strategy. Choose your product and process based on what your gear is made of.

- If your primary boots are full-grain leather: Your goal is both water resistance and leather health, so a wax-based conditioner is your best tool.

- If your primary boots are suede or nubuck: Your priority is preserving the finish while adding water resistance, so select a spray or cream specifically made for these materials.

- If your primary boots are fabric or synthetic: You are focused on renewing the factory DWR coating, making a simple spray-on treatment the most effective and efficient choice.

Properly maintaining your boots is a direct investment in your comfort and safety on the trail.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Choose the right treatment (wax, spray, cream) | Match product to boot material (leather, suede, fabric) |

| 2 | Thoroughly clean boots & remove laces | Ensure treatment bonds to material, not dirt |

| 3 | Apply product correctly, focusing on seams | Create a durable, water-resistant barrier |

| 4 | Air dry naturally away from direct heat | Allow treatment to cure properly without damaging boots |

Ready for Durable, Waterproof Hiking Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable hiking boots and shoes, built with quality materials and expert craftsmanship.

Let us help you provide your customers with reliable gear:

- Expert Manufacturing: We produce boots designed for longevity and performance.

- Bulk & Custom Orders: Scale your inventory with our efficient production lines.

- Quality Assurance: Deliver products that meet the highest standards.

Contact our team today to discuss your footwear needs and discover how we can support your business with reliable, high-quality hiking boots.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Oil Wax Leather Safety Boots for Bulk Purchase

People Also Ask

- What alternatives exist for extreme wet conditions beyond waterproof hiking boots? Discover the Best Footwear for Saturated Terrain

- What factors should be considered when choosing rain boots? Find the Perfect Boot for Your Needs

- What are the liner materials for rain boots? Cotton vs. Blends for Comfort & Durability

- What are rain boots made of? Discover the best materials for ultimate waterproof protection.

- What materials are used in snow boots and rain boots? A Guide to Waterproof Footwear