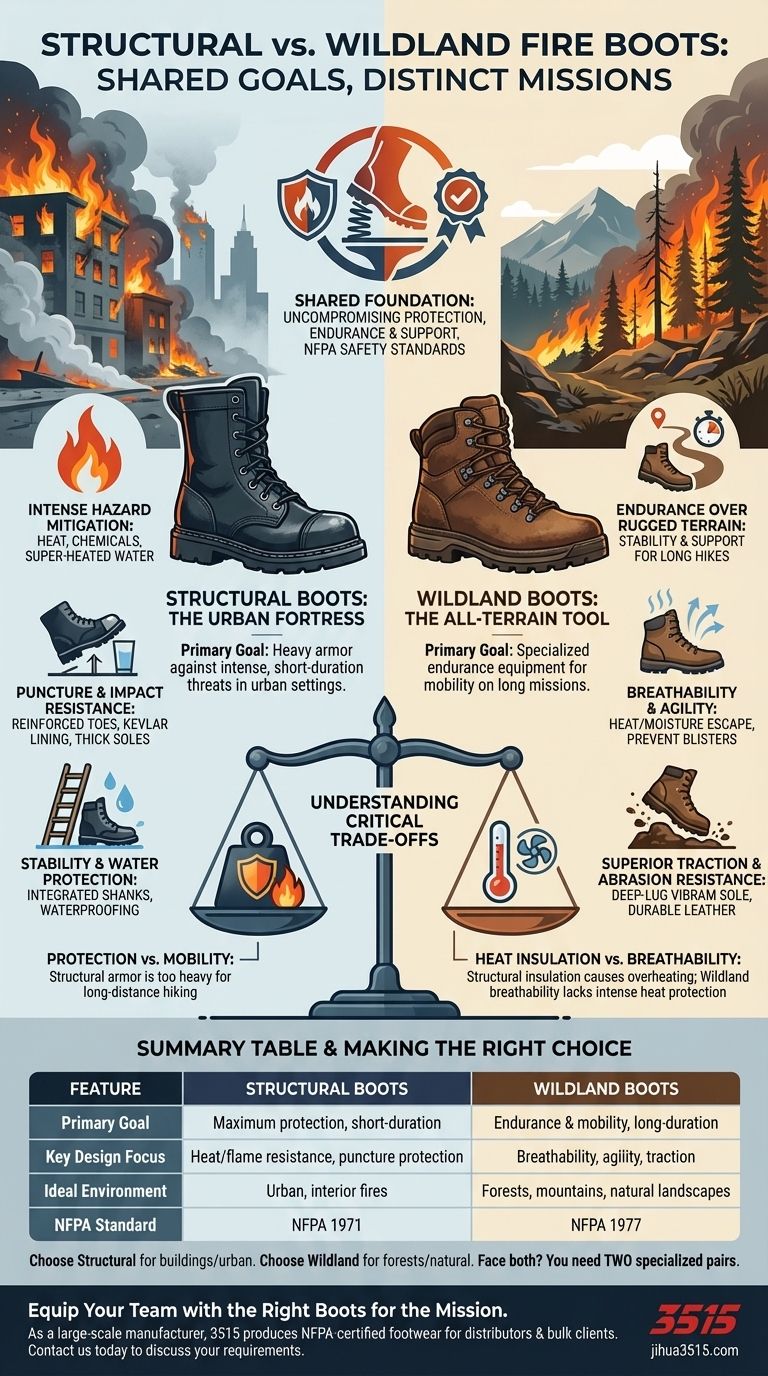

At their core, both structural and wildland firefighting boots are designed to achieve two fundamental goals: provide uncompromising protection from environmental hazards and deliver the ergonomic support needed to reduce fatigue during long, strenuous events. The critical difference lies in the specific hazards and physical demands of the environments they are built for.

The primary goal of a structural boot is to serve as heavy armor against intense, short-duration threats in urban settings. In contrast, a wildland boot functions as specialized endurance equipment, designed for mobility and stability during long-duration missions over rugged terrain.

The Universal Foundation: Shared Goals

Before examining their differences, it's crucial to understand the principles that unite all professional fire boots. These goals form the non-negotiable foundation of firefighter safety.

Uncompromising Protection

The first and most important goal is to shield the wearer from ground-level dangers. This includes resistance to heat, flames, punctures from sharp objects, and slips on unpredictable surfaces.

Endurance and Support

Firefighting is physically demanding. A boot must provide comfort and ergonomic support to minimize fatigue and prevent injury over many hours of continuous wear.

Adherence to Safety Standards

Both boot types must meet or exceed specific protective standards set by the National Fire Protection Association (NFPA). This certification ensures they have been rigorously tested for their intended use.

Structural Boots: The Urban Fortress

Structural firefighting boots are purpose-built for the unique and extreme dangers encountered when fighting fires inside buildings and in urban environments.

The Core Mission: Intense Hazard Mitigation

The primary goal is to provide maximum protection against extreme radiant heat from enclosed fires, potential chemical exposure, and contact with super-heated water and debris.

Key Design Goals: Puncture and Impact Resistance

These boots are engineered to protect against collapsed materials. Features like reinforced safety toes, puncture-resistant Kevlar linings, and thick rubber soles defend against nails, glass, and falling objects.

Key Design Goals: Stability and Water Protection

A taller shaft, typically 14 inches high, offers maximum protection to the leg. Integrated ladder shanks provide stability when climbing, and advanced waterproofing is essential for keeping feet dry in wet interior conditions.

Wildland Boots: The All-Terrain Tool

Wildland firefighting boots are designed for a completely different theater of operations: forests, mountains, and other natural landscapes where endurance is paramount.

The Core Mission: Endurance Over Rugged Terrain

The main objective is to function like a high-performance hiking boot built for fire. It must provide stability, comfort, and support for firefighters who may hike for miles over steep and uneven ground.

Key Design Goals: Breathability and Agility

Unlike a structural boot that seals heat out, a wildland boot must allow heat and moisture from physical exertion to escape. Breathability is key to preventing blisters and managing foot health during long shifts.

Key Design Goals: Superior Traction and Abrasion Resistance

The sole, often a deep-lug Vibram sole, is designed for exceptional grip on dirt, rock, and ash. The boot's exterior is made of thick, durable leather to resist abrasion from rocks and brush.

Understanding the Critical Trade-offs

Using the wrong boot for the mission is not just inefficient; it is dangerous. The design goals are often mutually exclusive, creating critical performance trade-offs.

Protection vs. Mobility

The heavy, armor-like construction of a structural boot provides superior impact and heat protection but would be prohibitively heavy and cumbersome for the long-distance hiking required in wildland firefighting.

Heat Insulation vs. Breathability

A structural boot's thick insulation is essential for entering a burning building but would cause a wildland firefighter's feet to overheat dangerously from metabolic heat. Conversely, a breathable wildland boot offers insufficient protection from the intense radiant heat of a structure fire.

Making the Right Choice for Your Mission

Your choice of boot must be directly aligned with the environment and tasks you will face.

- If your primary focus is fighting fires in buildings and urban environments: You need a structural boot that prioritizes maximum thermal insulation, puncture resistance, and impact protection.

- If your primary focus is combating fires in forests and natural landscapes: You need a wildland boot that prioritizes all-day comfort, breathability, and superior traction for hiking over uneven terrain.

- If you face both scenarios: You need two different, specialized pairs of boots, as one cannot safely or effectively perform the role of the other.

Understanding the specific design philosophy behind your boots is the first step toward ensuring safety and effectiveness on the fireground.

Summary Table:

| Feature | Structural Fire Boots | Wildland Fire Boots |

|---|---|---|

| Primary Goal | Maximum protection from intense, short-duration hazards | Endurance and mobility for long-duration missions |

| Key Design Focus | Heat/flame resistance, puncture protection, stability | Breathability, agility, superior traction on rugged terrain |

| Ideal Environment | Urban settings, interior structure fires | Forests, mountains, natural landscapes |

| NFPA Standard | NFPA 1971 | NFPA 1977 |

Equip Your Team with the Right Boots for the Mission

As a large-scale manufacturer, 3515 produces a comprehensive range of NFPA-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of professional fire boots, ensuring your team has the specialized gear they need for maximum safety and performance.

Contact us today to discuss your requirements and get a quote for reliable, high-performance firefighting footwear.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the characteristics of lineman boots? Essential Safety & Support for Utility Workers

- Why is it worth investing in a high-quality pair of moc toe boots? For Long-Term Value & Durability

- What advancements have been made in soft-toe boot design? From Durability to All-Day Comfort

- How can you ensure a comfortable fit when selecting oilfield work boots? A Guide to All-Day Comfort & Safety

- Which material is recommended for work boots in cold, wet environments? Neoprene for Superior Warmth

- Where are Western work boots appropriate and inappropriate to wear? A Guide to Function vs. Fashion

- Why are synthetic materials unsuitable for wildland fire boots? They Melt Under Extreme Heat

- What are the specific requirements for wildland firefighting boots under NFPA 1977? Essential Safety Guide