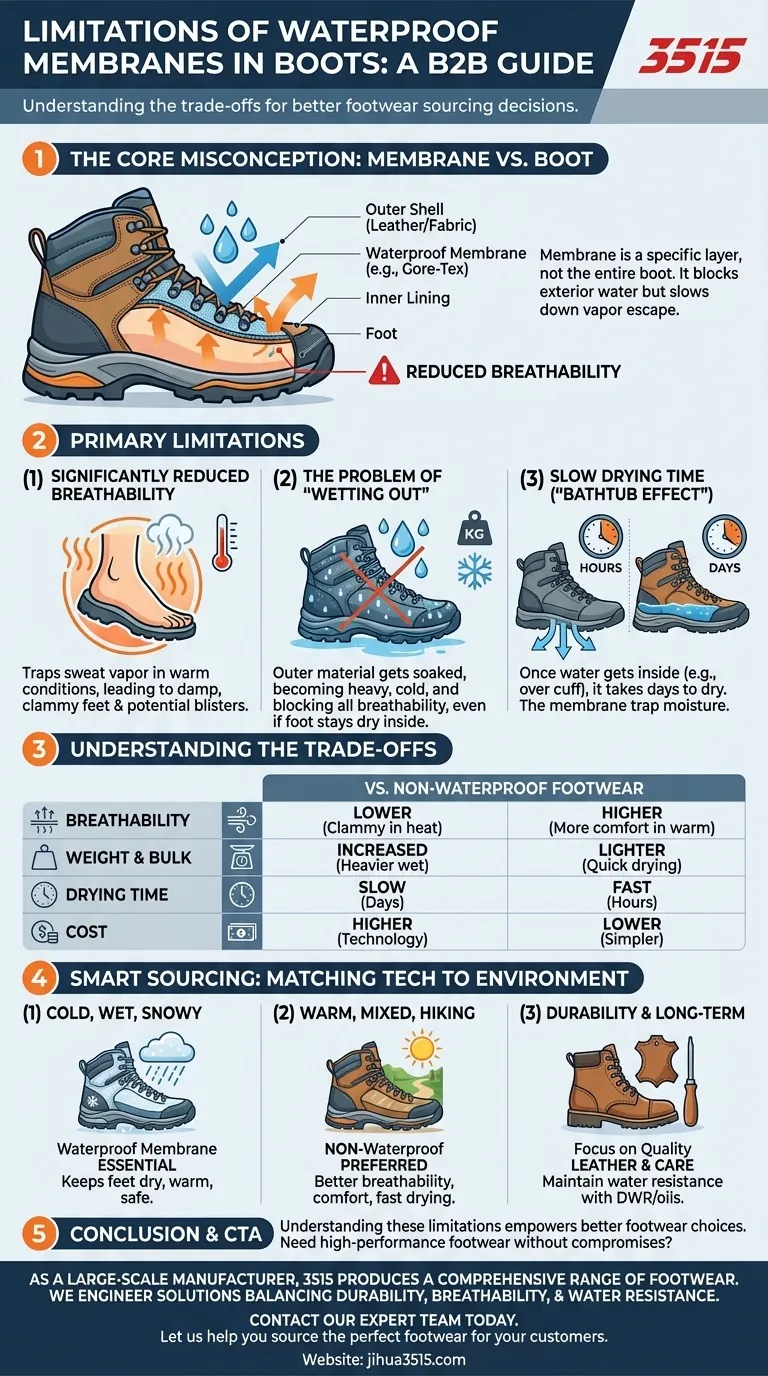

The primary limitations of waterproof membranes in boots are their significant reduction in breathability, their inability to protect the boot's outer material from getting soaked, and their slow drying time once water gets inside. These factors often lead to sweaty feet in warm conditions and heavier, waterlogged boots in wet environments.

A waterproof membrane is a specific layer designed to keep your foot dry, not to make the entire boot impervious to water. This distinction creates critical trade-offs in breathability, weight, and required maintenance that are essential to understand before you buy.

The Core Misconception: The Membrane vs. The Boot

Many users assume "waterproof boot" means the entire structure repels water. The reality is more complex and centers on a specialized internal layer.

How the Membrane Works

A waterproof membrane is a bootie-like liner, often made of a material like Gore-Tex, sandwiched between the boot's outer shell and inner lining.

Its microscopic pores are small enough to block larger water droplets from entering but large enough to allow smaller water vapor molecules (sweat) to escape.

The Problem of "Wetting Out"

While the membrane keeps your foot dry from the outside, it does nothing to protect the boot's upper materials, such as leather or nylon fabric.

When the outer material becomes saturated with water, a state known as "wetting out," the boot becomes heavy, cold, and loses all its breathability. Your sweat vapor can no longer escape through the water-clogged outer layer.

Why Outer Care Still Matters

This is why you must still treat the exterior of a waterproof boot with conditioning oils (for leather) or a Durable Water Repellent (DWR) spray (for fabric).

Proper care of the upper ensures water beads off the surface, maintaining the boot's light weight and, most importantly, its breathability.

Understanding the Key Trade-offs

Choosing a boot with a waterproof membrane is not a universal upgrade. It involves accepting several significant compromises.

Reduced Breathability

No membrane is as breathable as a boot without one. In warm or hot conditions, the membrane can't expel sweat vapor fast enough, leading to damp, clammy, and uncomfortable feet.

This trapped moisture can cause blisters and foot odor just as easily as external water can.

Increased Weight and Bulk

The addition of the membrane layer inherently adds weight and bulk to the boot's construction compared to a non-waterproof counterpart.

This effect is compounded when the outer material wets out, as you are now carrying the weight of the absorbed water with every step.

Slower Drying Times

The biggest liability of a waterproof membrane appears when water does get inside, for instance, by flowing over the top of the boot cuff when crossing a stream.

The same barrier that keeps water out also keeps it in. This creates a "bathtub effect," and the boot can take days to dry out completely, whereas a non-waterproof boot would drain and dry in hours.

Higher Cost

Boots featuring high-quality waterproof/breathable membranes are almost always more expensive than their non-waterproof equivalents due to the cost of the technology and more complex manufacturing.

How to Apply This to Your Decision

Choosing the right boot means matching the technology to the environment, not just defaulting to the "waterproof" label.

- If your primary focus is cold, wet, or snowy conditions: A waterproof membrane is essential for keeping your feet dry, warm, and safe from the elements.

- If your primary focus is hiking in warm or mixed weather: A non-waterproof, highly breathable boot will often provide more comfort and will dry much faster if it gets wet.

- If your primary focus is durability and long-term water resistance: Prioritize a high-quality leather boot and a consistent maintenance schedule over a fabric boot that relies solely on a membrane.

Understanding these limitations empowers you to choose footwear that truly serves your needs, rather than one that simply has a "waterproof" tag.

Summary Table:

| Limitation | Key Impact | Ideal Use Case |

|---|---|---|

| Reduced Breathability | Sweaty, clammy feet in warm conditions | Cold, wet, or snowy environments |

| Wetting Out (Saturated Outer) | Heavy, cold boots; loss of breathability | Requires consistent outer material care (DWR/oils) |

| Slow Drying Time | "Bathtub effect" if water enters; takes days to dry | Less suitable for wet/warm climates with stream crossings |

| Increased Weight & Cost | Bulkier construction and higher price point | Justified for specialized, harsh weather protection |

Need High-Performance Footwear Without the Compromises?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, allowing us to engineer solutions that balance durability, breathability, and water resistance based on your specific market needs.

Let us help you source or develop the perfect footwear for your customers.

Contact our expert team today to discuss your requirements and explore our extensive catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What was the original purpose of cowboy boots? A Functional Tool for Riders

- How do I convert my foot measurement to a shoe size? Find Your Perfect Fit Accurately

- What are the Kansei Engineering considerations for using 3D spacer fabric in foot orthotics? Elevate User Comfort

- What are the features of high-quality gaiters for competition riding? Achieve a Flawless Show Ring Look

- Why is PVDF piezoelectric film critical for self-powered smart insoles? Harvesting Energy with Flexible Durability

- What is the primary function of a shoe last? Mastering the 3D Mold for Perfect Fit and Structural Integrity

- What features make boots suitable for horseback riding? Essential Safety & Performance Guide

- How do crosslinking agents such as BTCA or MF improve the washing durability of sol-gel treated protective fabrics?