The primary limitations of PVC boots compared to rubber boots are their reduced flexibility, lower durability, and decreased comfort for long-term wear. PVC is a stiffer material that performs poorly in cold environments and has a shorter overall lifespan than traditional rubber.

While PVC boots offer a significant cost advantage, this comes at the expense of long-term performance. The core trade-off is choosing between the immediate affordability and light weight of PVC versus the superior durability, flexibility, and comfort of rubber.

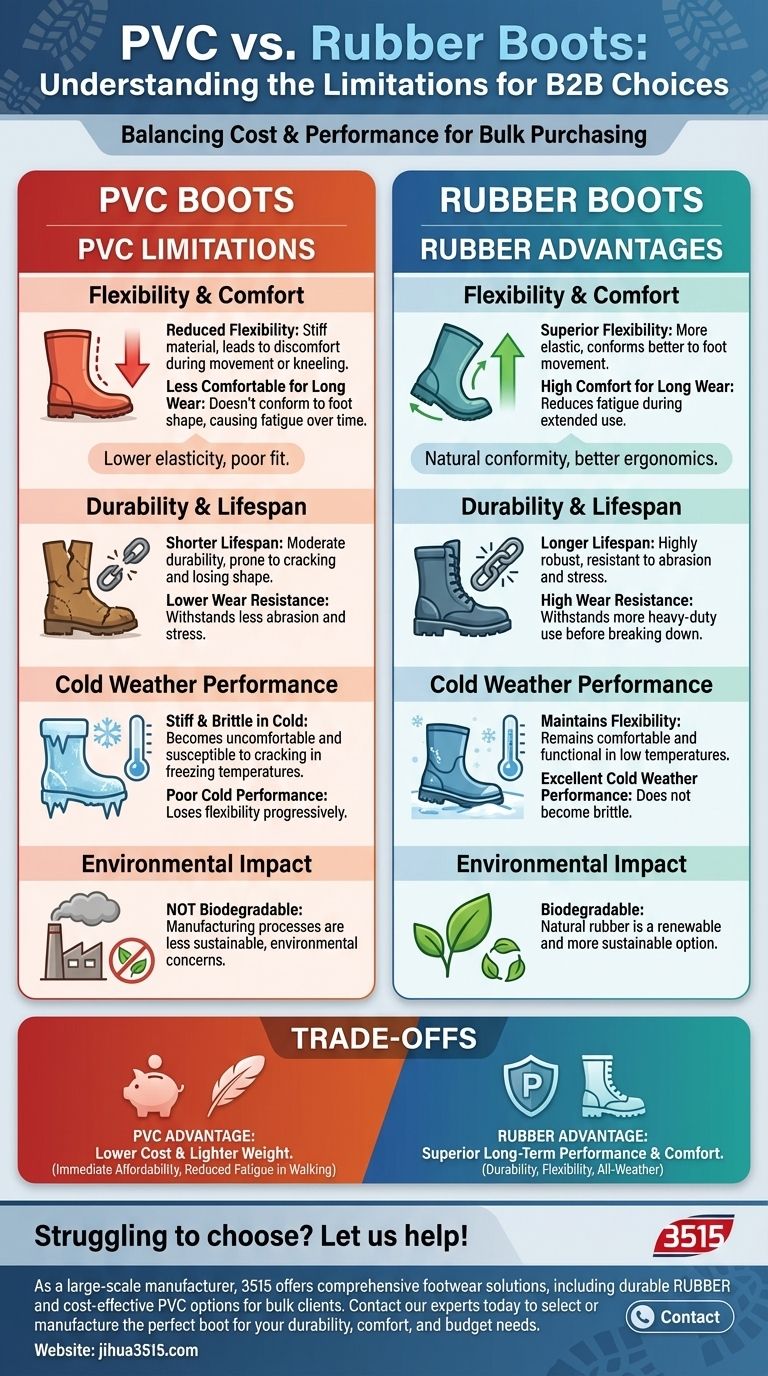

Key Differences in Material Properties

To understand the limitations, we must first look at the inherent characteristics of each material. PVC (Polyvinyl Chloride) and rubber have fundamentally different structures that dictate how they perform under stress and over time.

Flexibility and Comfort

PVC boots are significantly less flexible and elastic than their rubber counterparts. This inherent stiffness can lead to discomfort, especially during tasks that require a lot of movement or kneeling, such as gardening.

Because of this rigidity, PVC boots are often less comfortable for extended periods of wear. The material doesn't conform as well to the foot's natural movement, which can be a critical factor in a work environment.

Durability and Lifespan

Rubber is a more robust material with higher wear resistance. This means rubber boots can withstand more abrasion and stress before breaking down.

In contrast, PVC boots have moderate durability and a shorter lifespan. Over time, they are more prone to losing their original shape and developing cracks, particularly with frequent use.

Performance in Cold Weather

The difference in flexibility becomes even more pronounced in cold environments. As temperatures drop, PVC becomes progressively stiffer and more brittle.

This makes PVC boots less suitable for cold weather, as they not only become uncomfortable but are also more susceptible to cracking. Rubber, however, maintains its flexibility much better in lower temperatures.

Understanding the Trade-offs

Choosing between PVC and rubber is a classic case of balancing cost against long-term value. Neither material is universally superior; the right choice depends entirely on your specific needs and priorities.

The Advantage of Affordability

The most significant advantage of PVC is its lower cost. This makes PVC boots an accessible and practical option for occasional or light-duty tasks where a high-performance boot isn't necessary.

PVC is also lighter in weight than rubber. For jobs that involve a great deal of walking, this can reduce fatigue and make them a more practical choice, provided long-term durability is not the primary concern.

The Impact on the Environment

The production and disposal of PVC raise environmental concerns. The manufacturing process can generate harmful substances, and PVC is not biodegradable.

Rubber, especially natural rubber, is a more sustainable option. It is a renewable resource and will biodegrade over time, presenting a more environmentally friendly choice.

Making the Right Choice for Your Goal

Your decision should be guided by how you plan to use the boots. Consider the frequency of use, the environment, and your budget.

- If your primary focus is affordability for occasional, light-duty use: PVC boots are a logical and cost-effective choice.

- If your primary focus is long-term comfort, durability, and all-weather performance: Investing in a pair of rubber boots is the better decision.

- If your primary focus is environmental impact: Natural rubber boots are the more sustainable and responsible option.

Ultimately, understanding these material limitations empowers you to select the boot that truly serves your purpose.

Summary Table:

| Limitation | PVC Boots | Rubber Boots |

|---|---|---|

| Flexibility & Comfort | Less flexible, less comfortable for long wear | More flexible, conforms better to the foot |

| Durability & Lifespan | Moderate wear resistance, shorter lifespan | Higher wear resistance, longer lifespan |

| Cold Weather Performance | Becomes stiff and brittle | Maintains flexibility |

| Environmental Impact | Not biodegradable, less sustainable | More sustainable, especially natural rubber |

| Primary Advantage | Lower cost, lighter weight | Superior long-term performance and comfort |

Struggling to choose the right boot material for your business needs? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable rubber and cost-effective PVC options. We can help you select or manufacture the perfect boot to meet your specific durability, comfort, and budget requirements. Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

People Also Ask

- How does the lightweight nature of PVC boots benefit workers? Reduce Fatigue & Prevent Injury

- What are the UK sizes and corresponding insole lengths in inches for children's wellies? A Complete Guide to a Perfect Fit

- What are the pros and cons of heavy-duty wellington boots? Unmatched Protection vs. Key Trade-offs

- How is quality control maintained in gumboot production? Ensure Durability & Safety

- What factors should be considered when choosing waterproof footwear? Find the Perfect Balance for Your Needs

- What features are highlighted in women's gardening boots? Find the Perfect Fit for Comfort and Durability

- What are the primary raw materials for rubber gumboots? Natural Rubber vs. Synthetics Explained

- How should one decide between PVC and rubber for rain boots? A Guide to Choosing the Right Material