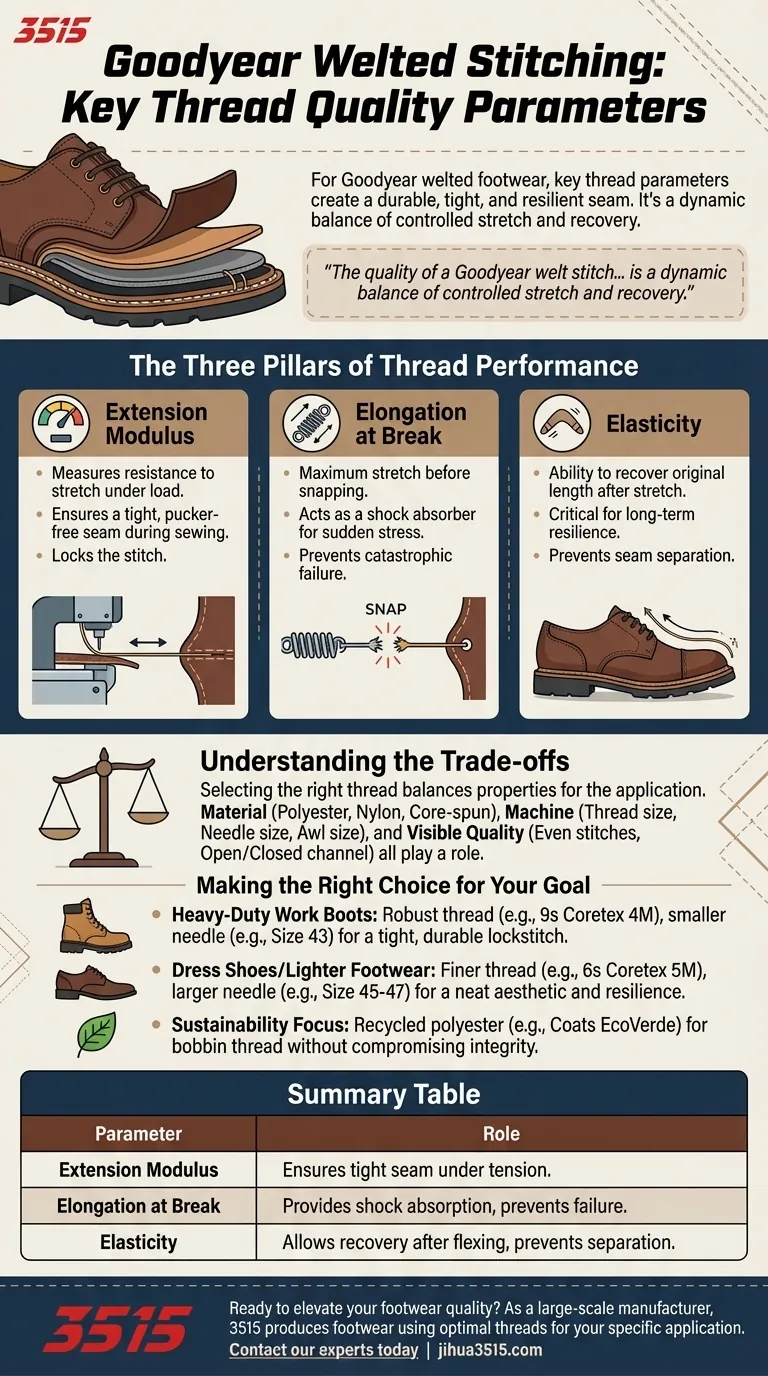

For Goodyear welted footwear, the key sewing thread quality parameters are Extension Modulus (how much it stretches under a specific load), Elongation at Break (the maximum it can stretch before snapping), and Elasticity (its ability to recover its original length after being stretched). These three properties work together to create a durable, tight, and resilient seam.

The quality of a Goodyear welt stitch isn't just about raw strength; it's about a dynamic balance of controlled stretch and recovery. The right thread ensures the seam can withstand the constant flexing of walking for years without loosening or failing.

The Three Pillars of Thread Performance

The construction of a Goodyear welted shoe places unique demands on the stitching thread. It must be strong enough to permanently join the upper, insole, and welt, yet flexible enough to endure millions of steps.

Extension Modulus: The Key to a Tight Seam

Extension Modulus measures the thread's resistance to stretching under a specific load. It's not about how much it can stretch, but how it behaves under the normal tension of the sewing machine.

A thread with the correct modulus allows the stitching machine to pull each stitch perfectly tight, locking it into the leather and welt. This creates a secure, pucker-free seam from the moment the shoe is made.

Elongation at Break: The Measure of Durability

Elongation at Break is the maximum percentage a thread can stretch before it snaps. This is a direct measure of its toughness and ability to handle sudden stress.

For a shoe that flexes and impacts the ground constantly, a high elongation at break acts as a shock absorber. It ensures the thread can withstand sharp tugs or extreme flexing without a catastrophic failure.

Elasticity: The Secret to Long-Term Resilience

Elasticity is arguably the most critical parameter for footwear. It is the thread's ability to return to its original length after being stretched.

With every step you take, the sole flexes and the welt seam is stretched. A thread with high elasticity will snap back, keeping the components tightly bound. Poor elasticity leads to the thread permanently stretching over time, resulting in loose stitches and seam separation.

Understanding the Trade-offs

Selecting the right thread is a matter of balancing competing properties to match the specific application. There is no single "best" thread for all Goodyear welted shoes.

Material Choice Dictates Properties

The thread's material—such as polyester, nylon, or linen—and its construction (e.g., a core-spun thread like Coretex) fundamentally determine its performance characteristics. Polyester, for example, often provides an excellent balance of strength and elasticity for this application.

The Machine and Thread Symbiosis

High-quality thread cannot perform correctly if it isn't paired with the right equipment. The thread size, needle size, and awl size must be perfectly matched to the leather thickness and shoe type.

Using a 6s thread for heavy-duty boots or a 9s thread for delicate dress shoes will compromise the stitch quality, regardless of the thread's inherent properties.

How Quality Becomes Visible

These technical parameters directly translate into the visible signs of a well-made shoe. A thread with consistent properties allows the machine to lay down perfectly even and neat stitches, a hallmark of quality craftsmanship.

Whether the shoe has an open channel sole (where stitches are visible) or a closed channel sole (where a flap of leather covers them), the underlying quality of the stitch depends entirely on the performance of the thread.

Making the Right Choice for Your Goal

Your choice of thread should be directly informed by the type of footwear you are constructing.

- If your primary focus is heavy-duty work boots: Opt for a more robust thread (e.g., 9s Coretex 4M) with high strength and controlled stretch, paired with a smaller needle (e.g., Size 43) to create a tight, durable lockstitch.

- If your primary focus is dress shoes or lighter footwear: A slightly finer thread (e.g., 6s Coretex 5M) with a larger needle (e.g., Size 45-47) provides a neater aesthetic while maintaining the necessary resilience for daily wear.

- If your primary focus is balancing performance with sustainability: Modern options like recycled polyester threads (e.g., Coats EcoVerde) can be used for the bobbin thread without compromising the structural integrity provided by the primary needle thread.

Ultimately, understanding these core thread parameters empowers you to create a product that is not only beautiful but fundamentally built to last.

Summary Table:

| Parameter | Role in Goodyear Welted Stitching |

|---|---|

| Extension Modulus | Ensures a tight, pucker-free seam under sewing machine tension. |

| Elongation at Break | Provides shock absorption and prevents catastrophic failure from stress. |

| Elasticity | Allows the thread to recover after flexing, preventing seam separation over time. |

Ready to elevate your footwear quality?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in material science and production ensures your Goodyear welted products are built to last, using the optimal thread for your specific application—from heavy-duty work boots to elegant dress shoes.

Contact our experts today to discuss your thread and manufacturing needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management