At its core, ASTM F2413-18 is the definitive US standard outlining the minimum performance requirements for protective footwear. To be compliant, a safety boot or shoe must meet foundational criteria for impact and compression resistance on the toe cap, and may also be rated for specialized protections against metatarsal injuries, electrical hazards, and punctures from below.

The standard isn't just a checklist of features; it's a performance-based system. A boot's compliance and specific protections are clearly communicated through a mandatory labeling system, allowing you to match the right footwear to the specific hazards of your workplace.

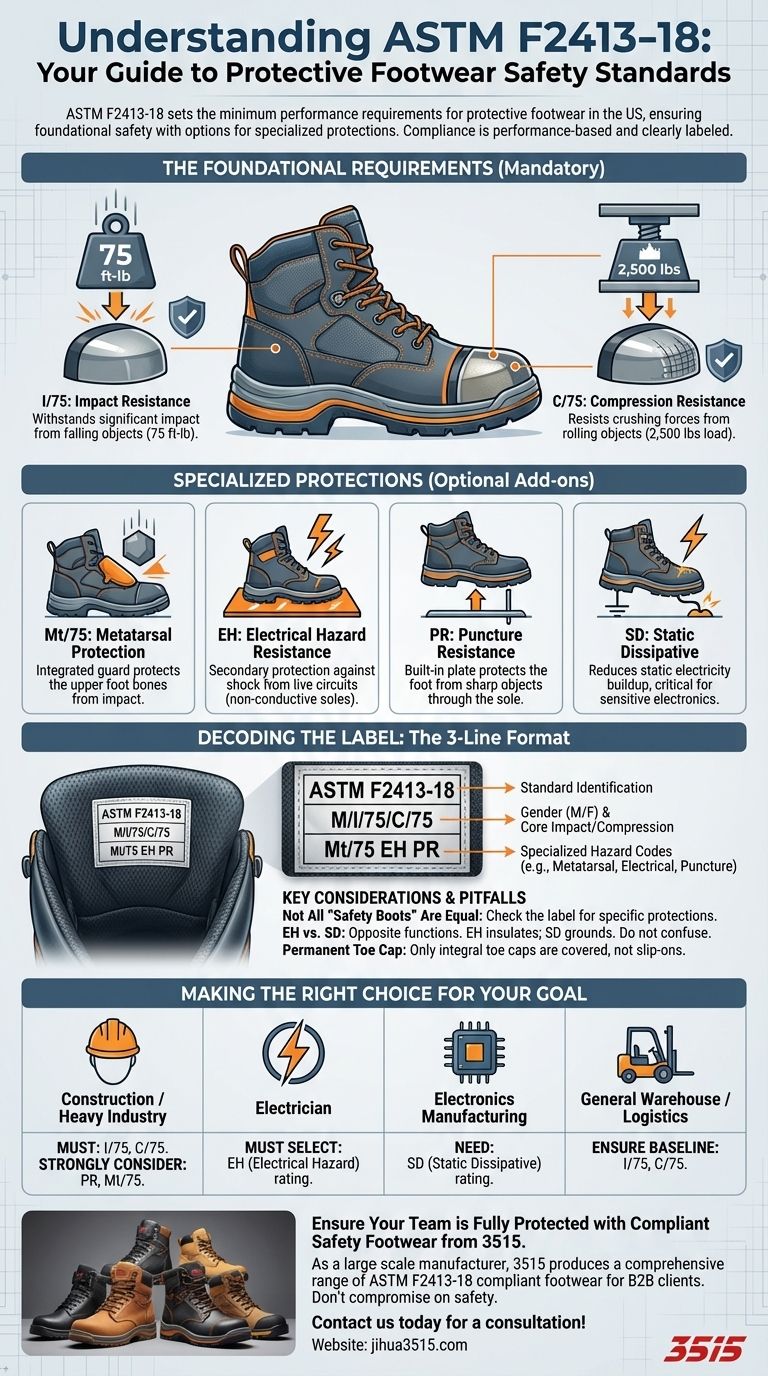

The Foundational Requirements: Impact and Compression

ASTM F2413-18 establishes a baseline for all safety toe cap footwear. Every compliant boot must pass rigorous tests for both impact and compression. These are non-negotiable and are always listed together on the label.

I/75: Impact Resistance

This requirement tests the protective toe cap's ability to withstand a significant impact from a falling object. The "75" rating signifies that the toe cap can protect the wearer's toes from a 75 foot-pound impact.

C/75: Compression Resistance

This tests the toe cap's ability to resist crushing forces from a rolling object. A "75" rating means the footwear can withstand a compressive load of up to 2,500 pounds before the toe cap begins to deform.

Specialized Protections for Specific Hazards

Beyond the basic toe cap requirements, the standard outlines several additional classifications for footwear designed to protect against specific, and often less common, workplace dangers.

Mt/75: Metatarsal Protection

This rating indicates the boot has an integrated guard that protects the upper foot (the metatarsal bones) from impact. It is crucial in environments where objects could drop or roll onto the top of the foot, not just the toes.

EH: Electrical Hazard Resistance

Footwear marked with EH is designed to provide a secondary source of protection against accidental contact with live electrical circuits. It is manufactured with non-conductive, electric-shock-resistant soles and heels.

PR: Puncture Resistance

This designation means the footwear has a puncture-resistant plate built into the sole to protect the foot from sharp objects from below, such as nails, scrap metal, or glass.

SD: Static Dissipative

SD footwear is designed to reduce the buildup of excess static electricity by conducting it from the body to the ground. This is critical in environments where a static discharge could damage sensitive electronics or ignite flammable materials.

Understanding the Label: How to Decode the Ratings

The most practical part of the ASTM F2413-18 standard is its clear labeling requirement. A compliant boot will have a label (typically on the tongue) with a three-line format that tells you everything you need to know.

The Three-Line Format

The label is structured to be read from top to bottom, moving from general compliance to the specific protections offered.

Line 1: Standard Identification

This line simply identifies the standard the boot conforms to. It will always read: ASTM F2413-18.

Line 2: Gender and Core Protections

This line shows the gender the boot is designed for (M for male, F for female) followed by the mandatory impact and compression ratings. It will look like this: M/I/75/C/75.

Line 3: Specialized Hazard Codes

This line lists any additional protections the boot provides, using the codes we've discussed. For example, a boot with metatarsal, electrical hazard, and puncture protection would read: Mt/75 EH PR.

Common Pitfalls to Avoid

Understanding the standard helps prevent critical safety mistakes. The label is your guide, but you must know what it's telling you and what it isn't.

Not All "Safety Boots" Are Equal

A steel toe boot is not automatically EH-rated or puncture-resistant. A boot only provides the protections explicitly listed on its ASTM label. Never assume a boot has a feature it doesn't advertise.

EH vs. SD: A Critical Distinction

These two ratings are fundamentally opposite and must not be confused. EH footwear insulates you from electricity, while SD footwear helps ground you to dissipate static. Using the wrong one can have dangerous or costly consequences.

The Importance of a Permanent Toe Cap

The ASTM F2413-18 standard applies only to footwear with a toe cap that is built in as an integral part of the shoe. Aftermarket slip-on toe caps or other temporary solutions are not covered by this standard.

Making the Right Choice for Your Goal

Use the ASTM label to ensure your footwear provides the exact protection required by your environment.

- If your primary focus is construction or heavy industry: You must have I/75 and C/75, and strongly consider boots with PR and Mt/75 ratings.

- If your primary focus is work as an electrician: You must select footwear with a specific EH rating to protect against shock.

- If your primary focus is manufacturing sensitive electronics: You need footwear with an SD rating to prevent static discharge from damaging components.

- If your primary focus is general warehouse or logistics work: Ensure the mandatory I/75 and C/75 ratings are present as a baseline for protection against falling items or rolling carts.

By understanding these requirements, you can move beyond simple compliance and make an informed decision that directly enhances workplace safety.

Summary Table:

| Requirement Code | Protection Type | Key Detail |

|---|---|---|

| I/75 | Impact Resistance | Withstands a 75 ft-lb impact on the toe cap. |

| C/75 | Compression Resistance | Resists a 2,500 lb compressive load on the toe cap. |

| Mt/75 | Metatarsal Protection | Guards the upper foot from impact. |

| EH | Electrical Hazard | Provides secondary protection against shock from live circuits. |

| PR | Puncture Resistance | Features a plate to protect against sharp objects from below. |

| SD | Static Dissipative | Reduces static electricity buildup in sensitive environments. |

Ensure Your Team is Fully Protected with Compliant Safety Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-18 compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the exact protection your workplace demands—from basic impact and compression to specialized metatarsal, electrical hazard, and puncture-resistant models.

Don't compromise on safety. Let us provide your team with durable, certified footwear that meets the highest standards.

Contact us today for a consultation and to discuss your specific needs!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- What does a grey rectangle symbol on safety footwear mean? A Guide to Grade 2 Toe Protection

- Why is high-load mechanical testing equipment necessary for safety footwear? Ensure Life-Saving Compression Resistance

- What organization develops safety standards for protective footwear in the U.S.? A Guide to ASTM and OSHA Compliance

- Why is heat resistance important in motorcycle boots? Protect Your Ride from Thermal Threats

- What does OSHA require for protective footwear? Ensure Full Compliance & Worker Safety

- How do damping materials in professional anti-vibration safety shoes protect the feet? High-Frequency Impact Reduction

- How does the comfort and ergonomic design of Safety Shoes influence operational safety? Boost Worker PPE Compliance

- What are the different types of safety toe boots available? Choose the Right Protection for Your Job