The key safety considerations when choosing work shoes are a direct match between the shoe's protective features and the specific hazards of your job site. This involves evaluating the need for safety toes for impact, puncture-resistant soles for sharp objects, slip-resistant outsoles for slick surfaces, and specialized guards against electrical, chemical, or thermal dangers.

Choosing the right work shoe is not about finding the shoe with the most features, but about methodically matching the right features to your specific job hazards, foot anatomy, and daily tasks.

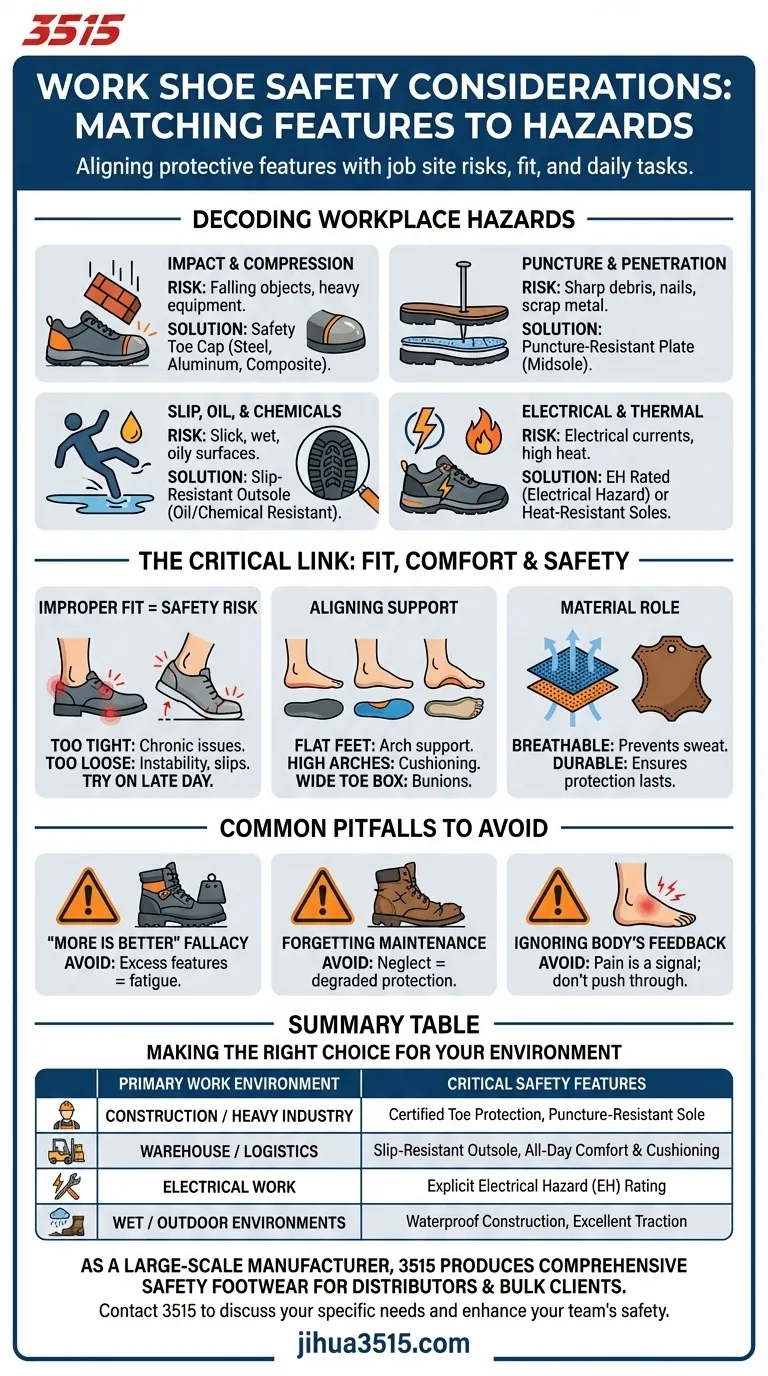

Decoding Your Workplace Hazards

The foundation of a safe choice is a clear understanding of your environment. A shoe that is perfect for a warehouse can be dangerously inadequate on a construction site.

Assessing Impact and Compression Risks

This is the most recognized safety feature, designed to protect your feet from falling objects or heavy rolling equipment.

The primary solution is a safety toe cap. These can be made of steel, aluminum, or non-metallic composite materials.

Understanding Puncture and Penetration Threats

Floors on job sites are often littered with nails, scrap metal, and other sharp debris that can easily penetrate a standard shoe sole.

Look for shoes with a puncture-resistant plate built into the midsole to protect the underside of your foot.

Evaluating Slip, Oil, and Chemical Resistance

Slips, trips, and falls are among the most common workplace accidents. The outsole of your shoe is your first line of defense.

A slip-resistant rating is critical for wet, oily, or smooth surfaces. Specific jobs may also require materials resistant to degradation from oils or industrial chemicals.

Identifying Electrical and Thermal Dangers

Certain jobs carry invisible risks that require specialized footwear.

Electrical Hazard (EH) rated shoes are built to impede the flow of electricity, crucial for electricians. Conversely, heat-resistant soles are essential for those working in high-temperature environments like paving or welding.

The Critical Link Between Fit, Comfort, and Safety

An unsafe shoe isn't just one that lacks a steel toe. A shoe that fits poorly creates distraction, fatigue, and instability, turning it into a safety hazard itself.

Why an Improper Fit Is a Safety Risk

Shoes that are too tight can cause chronic foot problems, while shoes that are too loose can lead to blisters and a lack of stability, increasing the risk of a slip or ankle roll.

Your feet can swell throughout the day, so it's best to try on shoes in the afternoon. Ensure there is enough room for any necessary insoles or specialized socks.

Aligning Support with Your Foot Type

Standard-issue shoes may not be right for your specific foot anatomy. Addressing your body's needs is essential for long-term health.

Workers with flat feet require strong arch support, while those with high arches benefit from extra cushioning. A wide toe box is essential for anyone with bunions to prevent pain and pressure.

The Role of Materials in All-Day Performance

The materials of the shoe dictate its breathability, durability, and weight, all of which impact both comfort and safety.

Breathable materials help prevent sweat and bacterial growth. Durable construction ensures the shoe's protective features don't fail prematurely.

Common Pitfalls to Avoid

Making an informed decision means knowing what mistakes to sidestep. The wrong choice can compromise your safety or lead to a wasted investment.

The "More Is Better" Fallacy

Choosing a shoe with every possible safety feature often results in a boot that is too heavy, stiff, and uncomfortable for your actual daily tasks, leading to unnecessary fatigue.

Forgetting About Maintenance

Your work shoes are a critical piece of safety equipment, just like a hard hat or safety glasses. They require proper care to function correctly.

Neglecting them can cause materials to become brittle and protective features to degrade, turning a safe shoe into a liability.

Ignoring Your Body's Feedback

Pain is a signal that something is wrong. Pushing through discomfort from an ill-fitting or improper shoe can lead to chronic conditions like plantar fasciitis.

Making the Right Choice for Your Environment

To simplify your decision, align your primary work environment with the most critical safety features.

- If your primary focus is construction or heavy industry: Prioritize certified toe protection (steel or composite) and a puncture-resistant sole plate.

- If your primary focus is warehouse work or logistics: Your top priority should be a certified slip-resistant outsole and all-day comfort with good cushioning.

- If your primary focus is electrical work: You must select a shoe that is explicitly labeled with an Electrical Hazard (EH) rating.

- If your primary focus is wet or outdoor environments: Look for genuine waterproof construction and excellent traction on varied terrain.

Investing in the right work shoe is a direct investment in your daily safety and your long-term health.

Summary Table:

| Primary Work Environment | Critical Safety Features to Prioritize |

|---|---|

| Construction / Heavy Industry | Certified toe protection (steel/composite), Puncture-resistant sole plate |

| Warehouse / Logistics | Certified slip-resistant outsole, All-day comfort & cushioning |

| Electrical Work | Explicit Electrical Hazard (EH) rating |

| Wet / Outdoor Environments | Genuine waterproof construction, Excellent traction on varied terrain |

Need work shoes that perfectly match your job's hazards?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the precise protective features, fit, and durability your workforce requires.

Contact 3515 today to discuss your specific needs and discover how our expertise can enhance your team's safety and comfort.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How is the environmental impact of safety boot production being addressed? Strategies for Sustainable Footwear

- Why is puncture resistance required on job sites? Essential Protection Against Sharp Hazards

- What is the function of electrical insulation materials in the design of safety footwear? Vital High-Voltage Protection

- How should you dry and maintain work shoe insoles? A Guide to Extending Comfort & Support

- Why are fully covered protective shoes recommended over open-toe footwear for diabetic foot ulcers? Critical for Safety & Prevention

- How does the application of lubricants assist in evaluating safety shoe performance? Master Slip Resistance Standards

- How do specialized safety shoes protect against battery maintenance injuries? Prevent Impact and Chemical Burns

- What are the key features of genuine leather work shoes? Understand the Trade-offs for Your Work