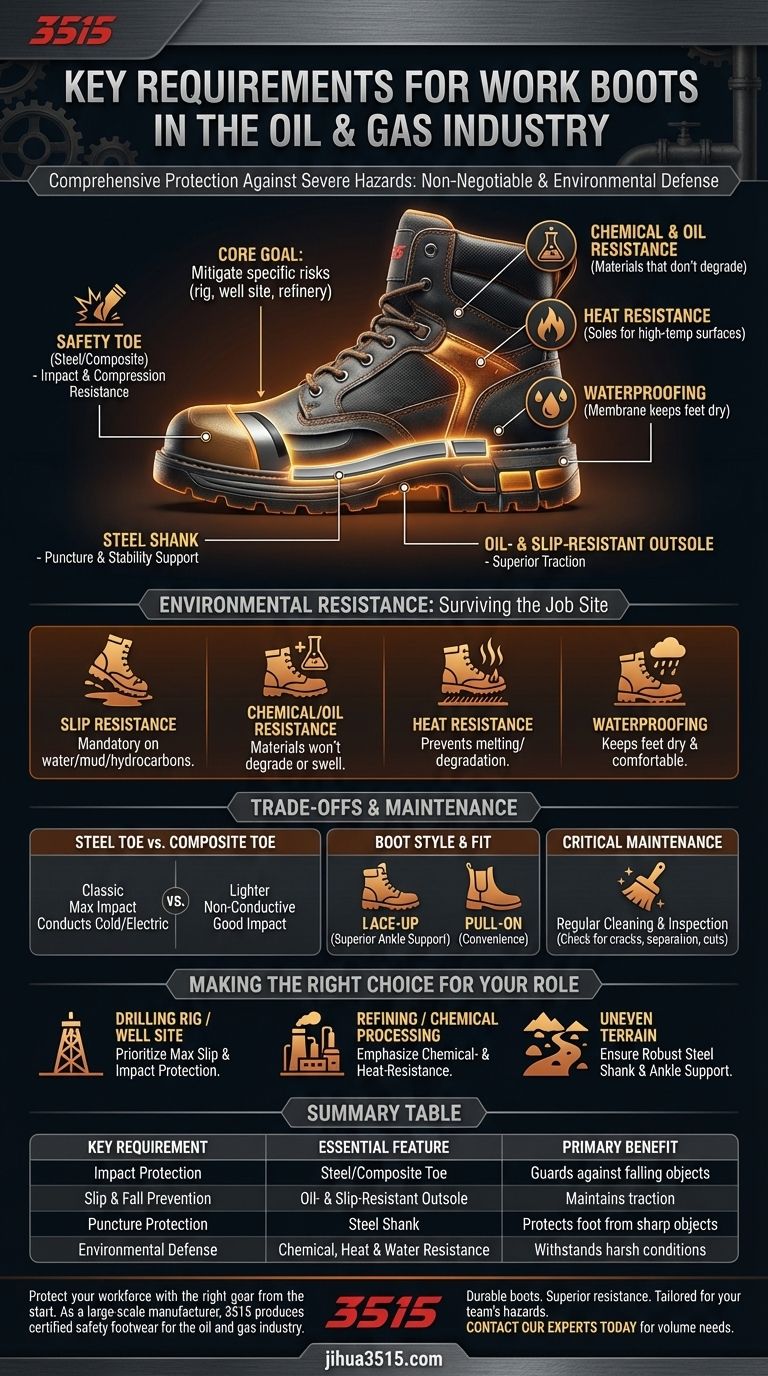

At its core, a work boot for the oil and gas industry is a highly specialized piece of personal protective equipment. It must feature a safety toe (typically steel), a slip-resistant and oil-resistant outsole, a stabilizing steel shank, and materials that can withstand chemicals, heat, and water.

The primary goal is not just durability, but comprehensive protection against a unique combination of severe hazards. Selecting the right boot involves understanding how each feature directly mitigates a specific risk present on a rig, well site, or refinery.

Non-Negotiable Protection: Guarding Against Immediate Hazards

The most immediate dangers in the oil and gas field are from heavy equipment and unstable surfaces. Your boots are the first line of defense.

Impact and Compression Resistance

All safety footwear must protect your toes from falling objects and crushing forces.

Steel-toed boots are the traditional standard, offering maximum protection against heavy impacts from pipes, tools, or machinery components.

Puncture and Stability Support

The ground on a worksite is rarely clean or even.

A steel shank, a rigid piece of metal built into the midsole, provides critical support on uneven terrain and protects the underside of your foot from punctures.

Environmental Resistance: Surviving the Job Site

Beyond physical impacts, oil and gas environments are chemically and thermally aggressive. The materials of your boot must be engineered to survive these conditions.

Superior Slip Resistance

Slips, trips, and falls are a leading cause of injury.

An oil- and slip-resistant outsole is absolutely mandatory. These soles are designed with specific tread patterns and compounds to maintain traction on surfaces contaminated with water, drilling mud, and hydrocarbons.

Chemical and Oil Resistance

Constant exposure to petroleum products will destroy standard footwear.

The boot’s upper materials and, most critically, its sole must be made from compounds that will not degrade, swell, or become brittle when exposed to crude oil, fuels, and other industrial chemicals.

Heat Resistance

High-temperature equipment and surfaces are common.

Heat-resistant soles are essential to prevent melting or degradation when coming into contact with hot pipes, engines, or ground surfaces found in refining or drilling operations.

Waterproofing

Work doesn't stop for weather, and sites are often wet.

A waterproof membrane or construction keeps feet dry, preventing discomfort, blisters, and potential loss of footing inside the boot.

Understanding the Trade-offs and Maintenance

No single boot is perfect for every single task. Understanding the nuances helps you make a more informed decision.

Steel Toe vs. Composite Toe

While steel is the classic choice, composite toes (made of materials like Kevlar, carbon fiber, or plastic) are a modern alternative.

Composite toes are lighter and do not conduct cold or electricity, but they may not offer the same level of extreme impact resistance as steel in all scenarios.

Boot Style and Fit

While some prefer traditional pull-on cowboy-style work boots for convenience, lace-up boots generally offer superior ankle support, which is critical on uneven ground.

Regardless of style, a proper fit is paramount for both safety and long-term comfort during 12-hour shifts.

The Critical Role of Maintenance

Your boots are a tool that requires upkeep.

Regular cleaning and inspection are not optional. You must check for cracks in the sole, separation between the sole and the upper, and deep cuts that could compromise the boot's chemical resistance or waterproof integrity.

Making the Right Choice for Your Role

Select your footwear based on the most prevalent hazards of your specific job function.

- If your primary focus is on a drilling rig or well site: Prioritize maximum slip resistance and superior impact protection from a steel toe.

- If your primary focus is in refining or chemical processing: Emphasize the boot's chemical- and heat-resistance ratings.

- If your primary focus involves extensive walking on uneven terrain: Ensure the boot has a robust steel shank and excellent ankle support.

Your choice of footwear is a foundational element of your personal safety on the job.

Summary Table:

| Key Requirement | Essential Feature | Primary Benefit |

|---|---|---|

| Impact Protection | Steel or Composite Safety Toe | Guards against heavy falling objects |

| Slip & Fall Prevention | Oil- & Slip-Resistant Outsole | Maintains traction on hazardous surfaces |

| Puncture Protection | Steel Shank | Protects foot from sharp objects, provides stability |

| Environmental Defense | Chemical, Heat & Water Resistance | Withstands harsh conditions, keeps feet dry and safe |

Protect your workforce with the right gear from the start.

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear tailored for the extreme demands of the oil and gas industry. We provide distributors, brand owners, and bulk clients with durable boots featuring steel toes, superior slip resistance, and chemical-resistant materials—all designed to mitigate the specific hazards your teams face daily.

Ready to equip your crew with reliable, high-performance footwear? Contact our experts today to discuss your specific requirements and volume needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- Why is investing in comfortable work boots important? Boost Health, Safety & Productivity

- What are some tips for measuring and fitting work boots correctly? Ensure All-Day Comfort and Safety

- What should be considered when choosing winter work boots? Key Factors for Safety & Warmth

- What clothing items complement the Outdoorsman/Heritage Look with moc toe boots? Build a Timeless, Rugged Wardrobe

- Which industries commonly use safety boots and why? Protect Your Workforce from Top Hazards

- How does high ankle support improve work boot performance? Prevent Sprains & Boost Stability

- How are PVC work boots typically manufactured? Discover the Efficient Injection Molding Process