The core composition of a PVC rain boot is not a single material, but a carefully formulated compound. The primary ingredients are Polyvinyl Chloride (PVC) resin, a plasticizer to add flexibility, a stabilizer to prevent breakdown during manufacturing, and various additives like colorants to achieve the final product specifications.

While PVC resin forms the boot's foundation, it is the precise blend of plasticizers and stabilizers that transforms a rigid plastic into a flexible, durable, and cost-effective piece of footwear. This formulation is a critical balancing act between performance and economy.

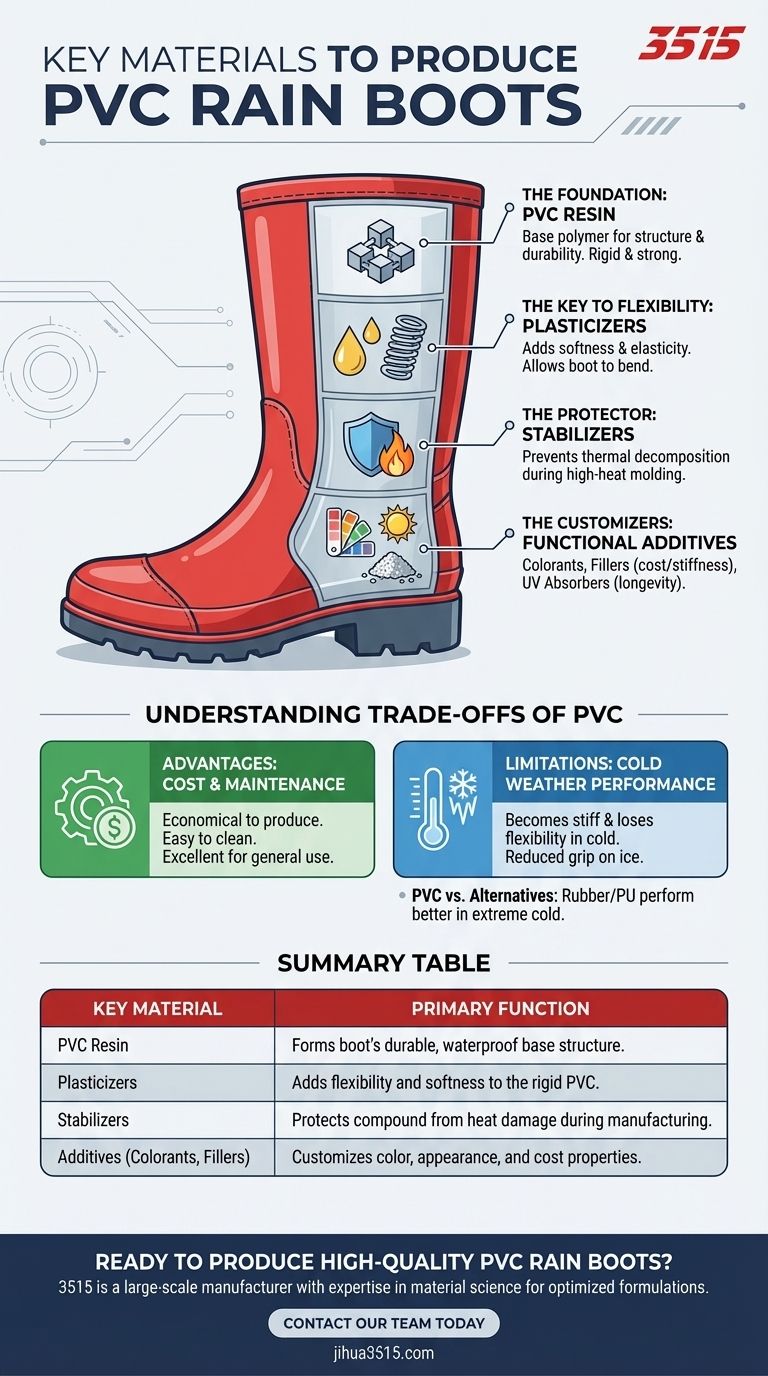

The Anatomy of a PVC Rain Boot Compound

To understand a PVC rain boot, you must first understand the purpose of each component in its chemical recipe. The raw materials are blended in a high-speed mixer to ensure an even distribution before the molding process begins.

The Foundation: PVC Resin

Polyvinyl Chloride (PVC) resin is the base polymer that gives the boot its fundamental structure and durability. In its raw form, PVC is a rigid, strong plastic known for its excellent resistance to water and many chemicals.

The Key to Flexibility: Plasticizers

A rigid plastic would make for a very uncomfortable boot. Plasticizers are oily substances added to the PVC resin to increase softness, flexibility, and elasticity, allowing the boot to bend with your foot.

The Protector: Stabilizers

The process of melting and molding PVC involves very high temperatures. Stabilizers are essential additives that protect the PVC compound from thermal decomposition during this high-heat processing, ensuring the final product is strong and free of defects.

The Customizers: Functional Additives

Beyond the core components, a range of other additives is used to meet specific requirements.

- Colorants provide the desired color and appearance.

- Fillers (like calcium carbonate) can be added to reduce cost and modify properties like stiffness.

- Antioxidants or UV absorbers may be included to improve longevity and prevent degradation from sun exposure.

Understanding the Trade-offs of PVC

Choosing PVC as a material for rain boots comes with a distinct set of advantages and limitations that are important to recognize.

The Primary Advantage: Cost and Maintenance

PVC rain boots are highly economical to produce and easy to maintain. This makes them an excellent, widely accessible option for providing effective protection against moisture for everyday tasks.

The Main Limitation: Cold Weather Performance

The primary drawback of PVC is its performance in cold temperatures. As the temperature drops, the plasticizer becomes less effective, causing the boot to lose flexibility and become stiff. This can also lead to a significant reduction in grip on icy surfaces.

How PVC Compares to Other Materials

While PVC is ideal for moderate climates and general use, other materials like natural rubber or polyurethane (PU) often perform better in more demanding conditions. Rubber, for instance, typically maintains its flexibility and grip far better in the cold.

Making the Right Choice for Your Goal

Your intended use case is the most critical factor in determining if a PVC rain boot is the correct choice.

- If your primary focus is general use and value: PVC is an excellent, economical choice for tasks like gardening or commuting in moderate, wet weather.

- If your primary focus is performance in cold climates: Consider alternatives like rubber or polyurethane, as a standard PVC boot will likely become stiff and lose traction.

Understanding this material blend allows you to select or produce a boot that is perfectly suited to its intended environment.

Summary Table:

| Key Material | Primary Function |

|---|---|

| PVC Resin | Forms the boot's durable, waterproof base structure. |

| Plasticizers | Adds flexibility and softness to the rigid PVC. |

| Stabilizers | Protects the compound from heat damage during manufacturing. |

| Additives (Colorants, Fillers) | Customizes color, appearance, and cost properties. |

Ready to produce high-quality PVC rain boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in material science ensures your PVC boot formulations are optimized for performance, durability, and cost-efficiency.

Let's discuss your production needs: Contact our team today to get a quote and learn how we can bring your footwear projects to life.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- In what hunting scenarios are rubber boots the best choice? Maximize Stealth & Dryness for Your Hunt

- How are PVC gumboots manufactured? A Look Inside the Injection Molding Process

- Can PVC and natural rubber be combined in boot manufacturing? Yes, as a cost-driven compromise.

- What are the environmental issues with modern Wellington boots? The Hidden Cost of PVC

- What are the advantages of handcrafted short Wellington boots? Superior Comfort & Versatility for Everyday Wear

- How should one decide between PVC and rubber for rain boots? A Guide to Choosing the Right Material

- What is the history and origin of Wellington boots? From Battlefield to Global Utility Staple

- What are the disadvantages of PVC boots compared to natural rubber? A Guide to Material Trade-offs