At its core, an engineer boot is a laceless, pull-on work boot defined by its utilitarian toughness. Its most recognizable features are a tall, unstructured "stovepipe" shaft, a plain rounded toe, and a dual buckle-and-strap system. One strap secures the fit over the instep (ankle), while a second adjusts the opening at the top of the shaft, all traditionally built from heavy full-grain leather.

The design philosophy of the engineer boot prioritizes durable protection and a secure, adjustable fit without the vulnerability of laces. Every defining characteristic stems from its origin as rugged workwear for men operating in harsh, demanding environments.

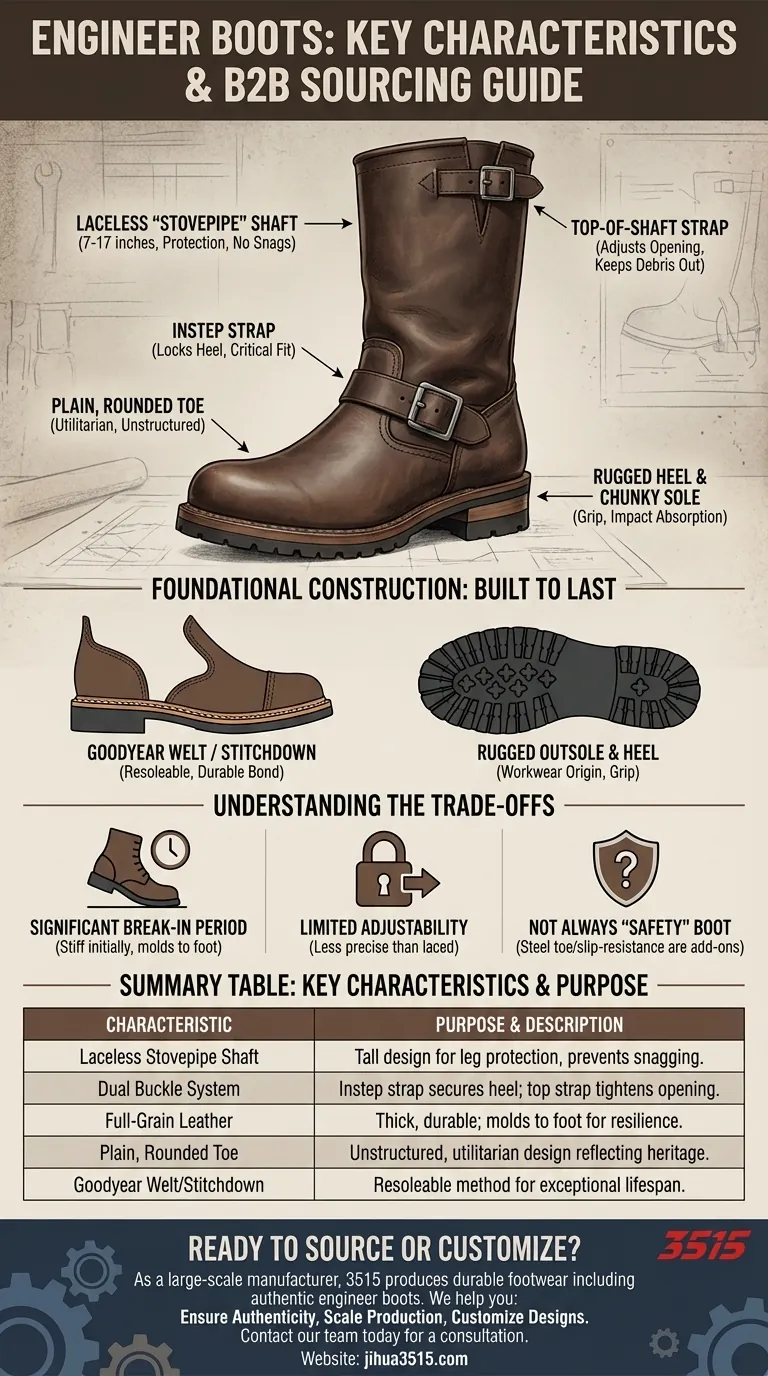

The Anatomy of an Engineer Boot

To truly identify an engineer boot, you must look beyond the general shape and understand its specific components. Each feature serves a distinct, practical purpose.

The Laceless Stovepipe Shaft

The shaft is the tall leather portion of the boot. In an engineer boot, it is typically an unadorned, straight tube, resembling a stovepipe.

This design, which can range from 7 to 17 inches, was originally meant to protect the feet and legs of steam engine firemen from hot coals and sharp objects. The lack of laces prevents snagging on machinery or controls.

The Dual Buckle System

This is the most iconic element. Unlike cowboy boots, which are purely pull-on, or chukka boots, which use laces, the engineer boot uses two straps for fit.

The instep strap, located over the ankle, is the most critical. It cinches down to lock your heel into the back of the boot, preventing excessive slippage.

The top-of-shaft strap allows the wearer to tighten the boot's opening around their calf, keeping out dirt and debris.

Full-Grain Leather Construction

True engineer boots are almost exclusively made from thick, durable full-grain leather, often in black or brown.

This material is chosen for its resilience and ability to mold to the wearer's foot over time. Many are made from oiled leather to enhance flexibility and water resistance.

The Plain, Rounded Toe

The front of the boot, or vamp, traditionally features a plain, unstructured round toe. This reflects its no-nonsense, utilitarian heritage.

In classic construction, the toe vamp piece is laid on top of the shaft leather where they meet, a subtle but traditional design detail.

Foundational Construction: Built to Last

The way an engineer boot is assembled is just as important as its visible features and is a key indicator of its quality and intended lifespan.

Goodyear Welt or Stitchdown

High-quality engineer boots use a Goodyear welt or a similar stitchdown construction.

These methods involve stitching the upper part of the boot to the sole. This creates an exceptionally durable bond and, most importantly, allows the boot to be resoled multiple times, dramatically extending its life.

The Rugged Heel and Sole

Reflecting their workwear origins, these boots feature a chunky, substantial sole and a defined heel.

The outsoles are typically made of rubber or a durable composite to provide grip and absorb impact, unlike the smooth leather soles often found on cowboy boots designed for stirrups.

Understanding the Trade-offs

The specific design of the engineer boot creates distinct advantages but also introduces compromises you must understand.

The Significant Break-in Period

The combination of thick full-grain leather and rugged construction means most engineer boots require a substantial break-in period. They are often stiff and unforgiving out of the box but will eventually mold to your foot for a custom fit.

Limited Adjustability

The primary trade-off for a laceless design is a less precise fit. While the instep strap is crucial, it cannot provide the same locked-in, micro-adjustable feel across the entire foot that a fully laced boot can.

Not Always a "Safety Boot"

A classic engineer boot is not automatically a certified safety boot. While some models incorporate steel toes, penetration-resistant midsoles, or slip-resistant soles, these features are specific additions. The core design itself does not guarantee these modern safety ratings.

Making the Right Choice for Your Goal

Your intended use should guide which characteristics you prioritize when evaluating a pair of engineer boots.

- If your primary focus is protection and durability (e.g., for motorcycling): Prioritize a tall, heavy full-grain leather shaft and a resoleable Goodyear welt construction for longevity.

- If your primary focus is timeless style: Look for classic proportions, a clean plain toe, and quality metal hardware on the buckles, as these elements define its iconic silhouette.

- If your primary focus is achieving a comfortable fit: Recognize the limitations of a laceless design and be prepared for a significant break-in period or seek out brands known for specific lasts that match your foot shape.

Understanding these core characteristics empowers you to identify a true engineer boot and appreciate its purpose-driven design.

Summary Table:

| Key Characteristic | Purpose & Description |

|---|---|

| Laceless Stovepipe Shaft | Tall, straight design (7-17 inches) for leg protection; prevents snagging on machinery. |

| Dual Buckle System | Instep strap secures heel; top-of-shaft strap tightens calf opening to keep out debris. |

| Full-Grain Leather | Thick, durable material that molds to the foot for resilience and water resistance. |

| Plain, Rounded Toe | Unstructured, utilitarian design reflecting the boot's no-nonsense workwear heritage. |

| Goodyear Welt/Stitchdown | Resoleable construction method for exceptional durability and long boot lifespan. |

Ready to Source or Customize Your Own Line of Engineer Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots, including authentic engineer boots built to your exact specifications.

We can help you:

- Ensure Authenticity: Leverage our expertise to produce boots with true engineer boot characteristics.

- Scale Production: Meet large-volume orders with consistent quality and reliable delivery.

- Customize Designs: Tailor materials, hardware, and construction to fit your brand and market.

Let's discuss your project and how we can bring your vision to life.

Contact our team today for a consultation

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- High Performance Fire-Retardant Waterproof Safety Boots

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What specific mechanical protections do industrial safety shoes provide in cable factories? Expert Guide for Max Safety

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is Production Capacity (Mcap) a core parameter in safety shoe contracts? Optimize Supply and Mitigate Risk