At their core, work boots are specialized footwear engineered around three principles: uncompromising protection, job-specific support, and long-term durability. Unlike standard shoes, every component—from the sole to the upper—is designed to shield you from workplace hazards, provide stability on unpredictable surfaces, and withstand the rigors of demanding physical labor.

The defining characteristic of a work boot is not a single feature, but its purpose-built design. The right boot isn't the one with the most safety ratings, but the one with the correct combination of protection, support, and traction for your specific work environment.

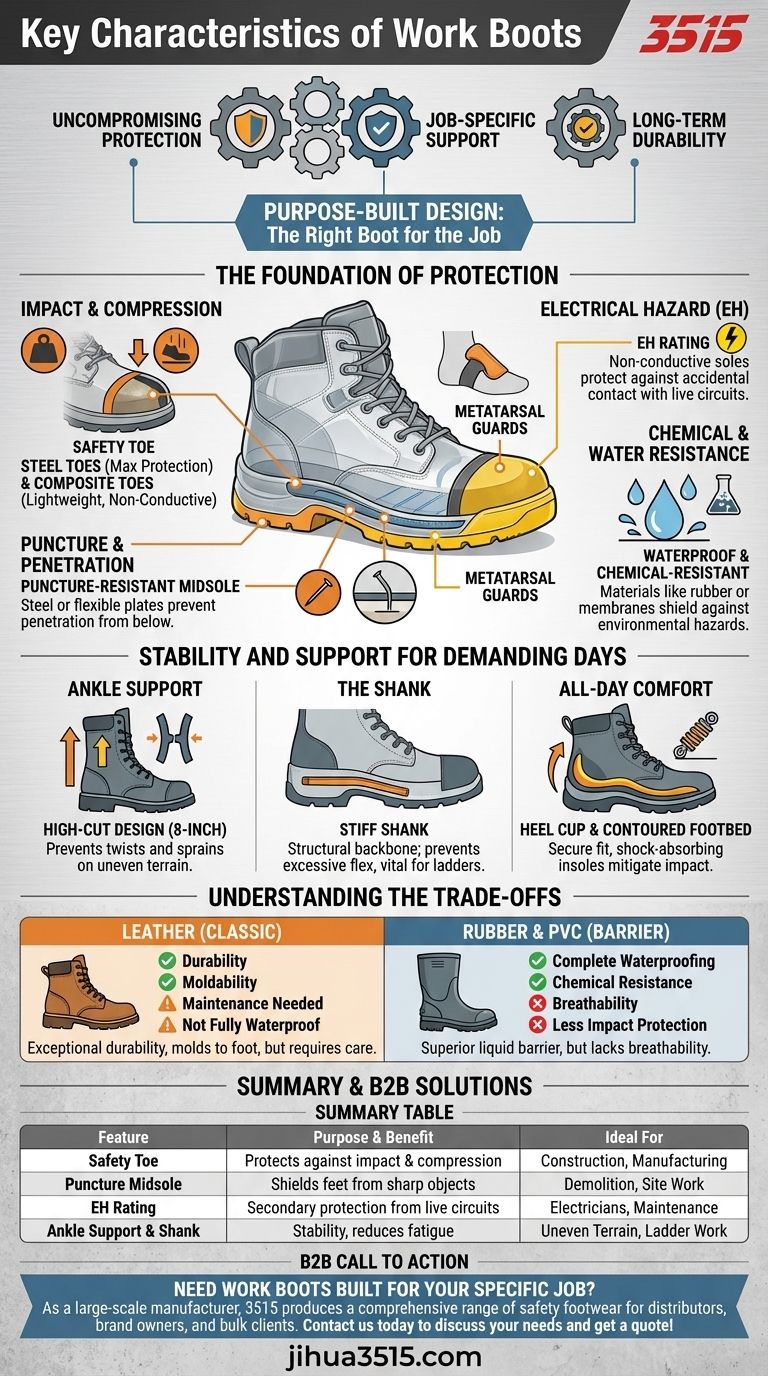

The Foundation of Protection: Core Safety Features

A work boot's primary function is to act as the first line of defense for your feet. The specific features required are dictated entirely by the hazards you face daily.

Impact and Compression Resistance

The most recognized safety feature is the safety toe. These are reinforced caps designed to protect your toes from falling objects and compression.

They typically come in two varieties: steel toes for maximum protection and composite toes, which are lighter and don't conduct electricity or temperature.

Puncture and Penetration Guards

For environments with sharp objects like nails or metal shards, boots can be equipped with puncture-resistant midsoles. These are plates, often made of steel or flexible composites, embedded in the sole to prevent penetration from below.

More advanced boots may also feature metatarsal guards, which protect the delicate bones on the top of your foot.

Electrical Hazard (EH) Rating

Certain boots are designed with non-conductive soles and heels to provide a secondary source of protection against accidental contact with live electrical circuits. This is a critical feature for electricians and maintenance workers.

Chemical and Water Resistance

Materials and construction play a key role in protecting you from environmental hazards. Waterproof boots are essential for plumbers and outdoor workers, while chemical-resistant models made of rubber or PVC are necessary for handling hazardous materials.

Stability and Support for Demanding Days

Beyond preventing acute injuries, work boots are engineered to reduce the fatigue and strain of being on your feet all day.

The Importance of Ankle Support

Most work boots feature a high-cut design that extends above the ankle. This provides crucial support, helping to prevent twists and sprains on uneven terrain or when carrying heavy loads. An 8-inch height is a common standard for robust support.

The Shank: Your Boot's Backbone

A stiff shank, a structural piece between the insole and outsole, prevents the boot from flexing excessively. This is vital for maintaining shape and providing a stable platform, especially when climbing ladders where the rungs press into the arch of your foot.

All-Day Comfort and Fit

Proper support comes from features that hold your foot securely. A well-designed heel cup and a contoured footbed prevent your foot from sliding, which reduces friction and fatigue. Quality shock-absorbing insoles are also critical for mitigating the constant impact of walking on hard surfaces.

Understanding the Trade-offs

Choosing a work boot always involves balancing competing priorities. No single boot is perfect for every task, and the primary trade-off often comes down to the material.

Leather: The Classic All-Rounder

Leather is prized for its exceptional durability, moisture resistance, and ability to mold to the wearer's foot over time. However, it requires maintenance and is generally not fully waterproof without a specialized membrane.

Rubber and PVC: The Liquid Barrier

For complete protection against water, mud, and many chemicals, rubber or PVC is the superior choice. The major downside is a near-total lack of breathability, which can be uncomfortable during long shifts or in warm weather. They also offer less impact protection than a sturdy leather boot.

Construction and Outsoles

The method used to attach the sole to the upper, such as a Goodyear storm welt, significantly increases a boot's durability and water resistance. The outsole itself is specialized for traction; a lug sole excels on mud and uneven ground, while a softer wedge outsole maximizes surface contact for grip on slippery concrete floors.

Making the Right Choice for Your Job

Selecting the right features is about accurately assessing your daily environment and prioritizing the protections you truly need.

- If your primary focus is construction or carpentry: Prioritize boots with excellent ankle support, a stiff shank for ladder work, and a certified safety toe for impact protection.

- If your primary focus is as a mechanic or in a factory: Emphasize slip-and-oil-resistant outsoles and consider a lightweight composite toe for all-day comfort on hard floors.

- If your primary focus is plumbing or wet environments: Select fully waterproof boots, often made of rubber or featuring a sealed welt construction, with aggressive non-slip tread.

- If your primary focus is heavy industry or demolition: Look for maximum protection, including metatarsal guards and puncture-resistant soles, in addition to standard safety toes.

Choosing the right work boot is a direct investment in your personal safety, daily comfort, and long-term performance.

Summary Table:

| Key Characteristic | Purpose & Benefit |

|---|---|

| Safety Toe (Steel/Composite) | Protects toes from impact and compression hazards |

| Puncture-Resistant Midsole | Shields feet from sharp objects penetrating the sole |

| Electrical Hazard (EH) Rating | Provides secondary protection against live circuits |

| Ankle Support & Shank | Offers stability and reduces fatigue on uneven terrain |

| Material (Leather/Rubber) | Balances durability, water resistance, and breathability |

Need work boots built for your specific job? As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective boots and shoes, ensuring you get the exact combination of safety features, support, and durability your team requires. Contact us today to discuss your needs and get a quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What are the key safety standards for work boots? Choose the Right Protection for Your Job

- How to choose the right work boot? Match Safety Features to Your Job's Hazards

- What features should construction and industrial work boots have? Essential Safety & Protection Guide

- What are the key benefits of PVC boots compared to traditional leather boots? Find Your Perfect Work Boot Match

- Why is it important to invest in a good pair of work boots? Maximize Safety & Save Money Long-Term

- Which brands are known for producing high-quality engineer boots? Invest in Boots Built to Last a Lifetime

- What features make for good quality work boots? A Guide to Durable Construction & Safety

- What should you check when shopping for non-conductive work boots? Verify the EH Rating for Maximum Safety