At its core, an engineer boot is a laceless, American-style work boot defined by its exceptional durability and distinctive buckle system. It features a tall leather shaft, a plain rounded toe, and adjustable straps at both the instep and the top of the shaft to secure the foot. This design was originally built for protection and has since become an icon of rugged, functional style.

The key attributes of an engineer boot are not just aesthetic choices; they are a direct reflection of its heritage as protective wear for workers and motorcyclists. The laceless design, tall shaft, and dual-buckle system work in concert to deliver a unique blend of safety, durability, and a secure fit.

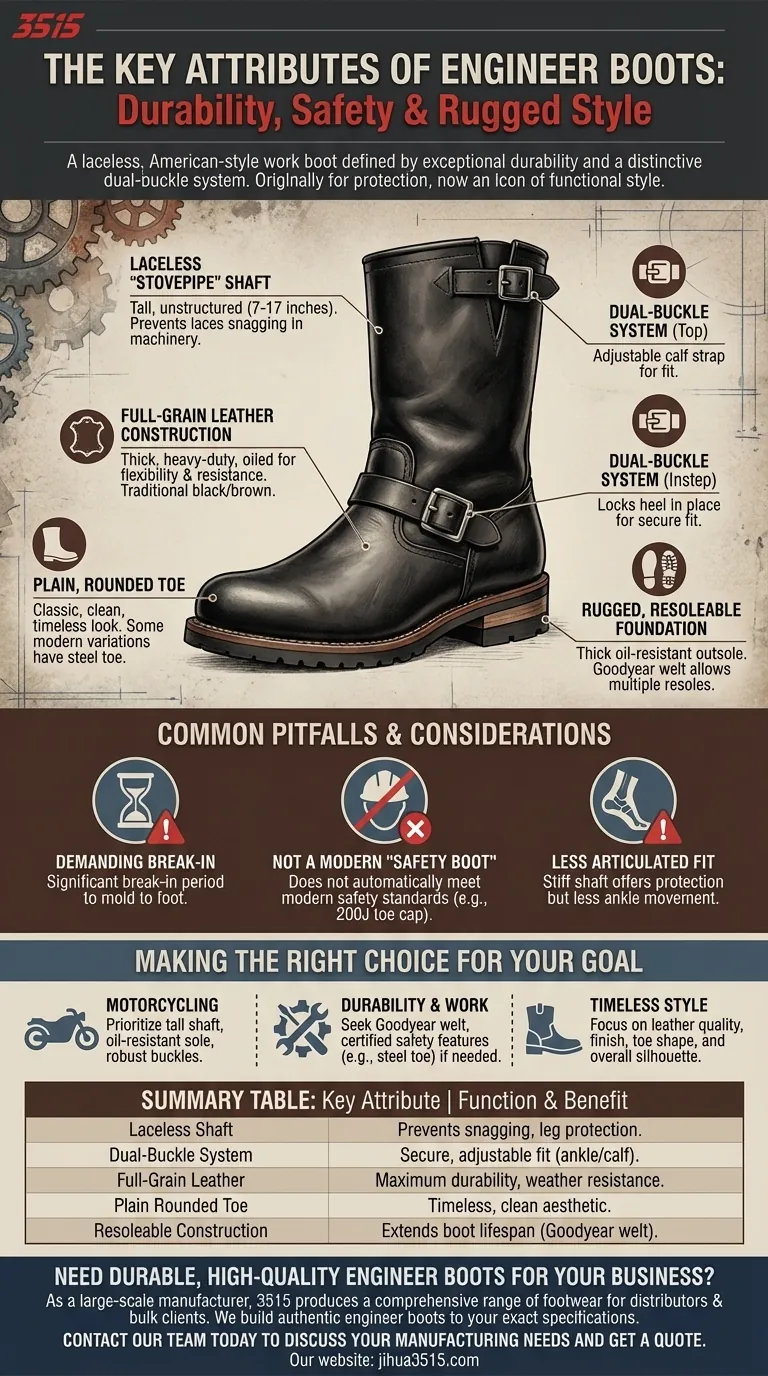

The Anatomy of an Engineer Boot

To truly understand what makes an engineer boot, we must examine its core components. Each feature serves a specific, practical purpose that contributes to its iconic status.

The Laceless "Stovepipe" Shaft

Engineer boots feature a tall, unstructured shaft, often called a "stovepipe" leg. This shaft can range from 7 to 17 inches in height.

The most critical feature is the complete absence of laces. This was a crucial safety design for its original wearers—railroad engineers—preventing laces from getting caught in moving machinery.

The Dual-Buckle System

In place of laces, engineer boots use an adjustable system of leather straps and metal buckles.

One strap is located over the instep (or ankle) to lock the heel in place and provide a secure fit. A second buckle is positioned at the top of the shaft, allowing the wearer to adjust the calf for a tighter or looser fit.

Full-Grain Leather Construction

Durability is paramount, so these boots are almost always constructed from thick, heavy-duty full-grain leather.

This leather is frequently oiled to increase its flexibility and resistance to the elements. Black and brown are the most traditional and common colors.

A Plain, Rounded Toe

The classic silhouette of an engineer boot includes a simple, unadorned rounded toe. This contributes to its clean and timeless look.

While the original design is plain, some modern variations intended for heavy work may include steel toe reinforcements for added protection.

Rugged, Resoleable Foundation

The boot's foundation is built for longevity. They typically feature thick neoprene or rubber outsoles that are oil-resistant for reliable traction.

High-quality engineer boots use a Goodyear welt or stitch-down construction. This stitching method allows the boot to be resoled multiple times, vastly extending its functional lifespan.

Common Pitfalls and Considerations

While iconic, the unique design of engineer boots comes with specific trade-offs that are important to understand before making a choice.

The Demanding Break-in Period

The thick, robust full-grain leather required for durability means engineer boots often have a significant break-in period. They must be worn over time to soften and mold to the unique shape of your foot.

Not a Modern "Safety Boot" by Default

While originating as protective workwear, a classic engineer boot does not automatically meet modern safety standards.

Unless explicitly stated, they do not have certified features like 200-joule protective toe caps or midsole penetration resistance found in today's regulated safety footwear.

A Less Articulated Fit

The tall, stiff shaft provides excellent protection but can offer less ankle articulation compared to a shorter, laced boot. The fit is secured by two points of contact rather than the distributed pressure of a full lacing system.

Making the Right Choice for Your Goal

Selecting the right engineer boot depends entirely on its intended purpose.

- If your primary focus is motorcycling: Prioritize a taller shaft for maximum leg protection, a confirmed oil-resistant sole, and a robust buckle system that will hold securely at high speeds.

- If your primary focus is durability and work: Seek out a boot with a Goodyear welt construction for resoling and verify if it includes certified safety features like a steel toe if your environment requires it.

- If your primary focus is timeless style: Concentrate on the quality and finish of the leather, the specific shape of the toe, and the overall silhouette that best complements your personal aesthetic.

Ultimately, understanding these core attributes empowers you to recognize a true engineer boot and select one that perfectly balances form and function for your needs.

Summary Table:

| Key Attribute | Function & Benefit |

|---|---|

| Laceless 'Stovepipe' Shaft | Prevents snagging, provides leg protection. |

| Dual-Buckle System | Ensures a secure, adjustable fit at ankle and calf. |

| Full-Grain Leather | Offers maximum durability and weather resistance. |

| Plain Rounded Toe | Contributes to a timeless, clean aesthetic. |

| Resoleable Construction | Extends boot lifespan (e.g., Goodyear welt). |

Need durable, high-quality engineer boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including authentic engineer boots built to your exact specifications for durability, safety, and style.

Contact our team today to discuss your manufacturing needs and get a quote.

Visual Guide

Related Products

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- Why is rotating two pairs of work boots recommended? Double Boot Life & Boost Foot Health

- What is the difference between a cowboy boot and a work boot? Choosing the Right Footwear for Your Task