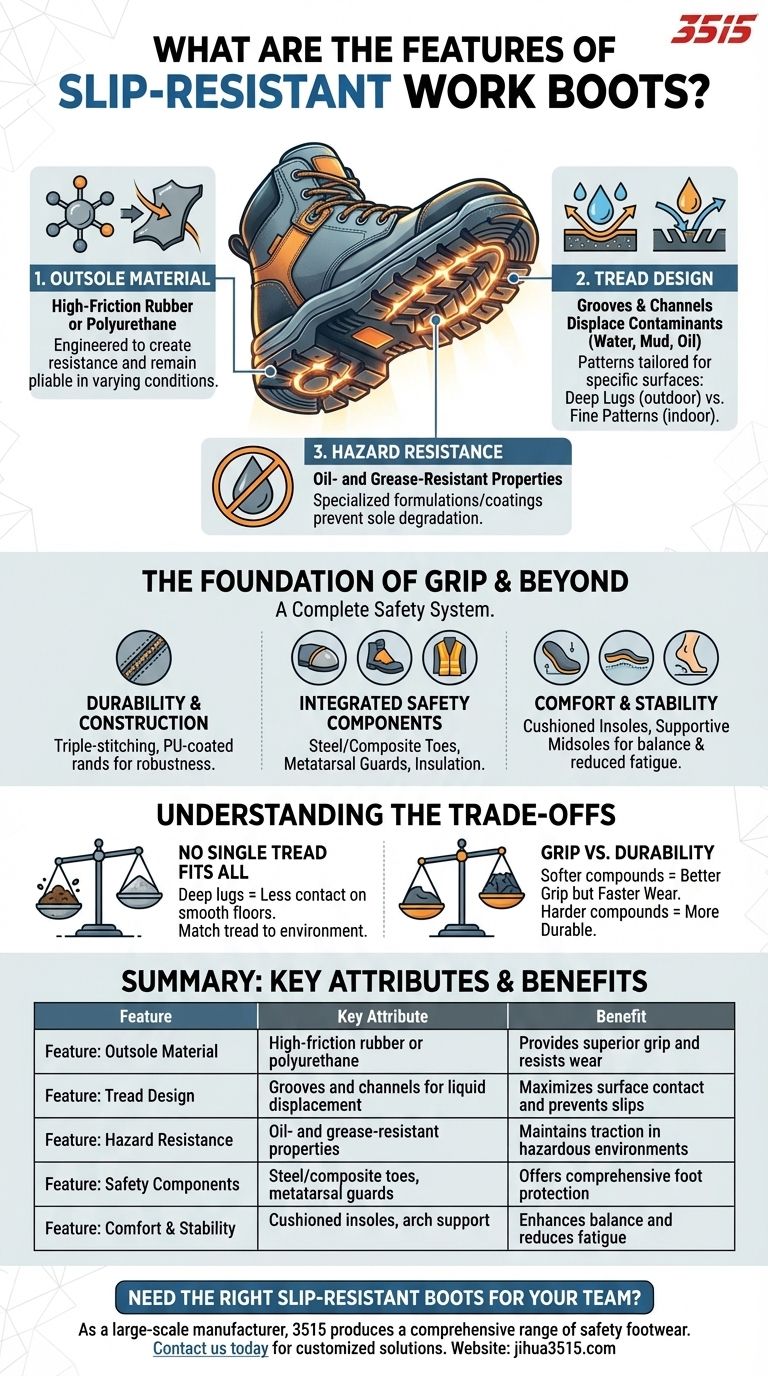

At their core, slip-resistant work boots are defined by three key features: the material of the outsole, the design of its tread, and its ability to resist contaminants. These elements work together as a system to maximize friction on hazardous surfaces. They typically use high-friction rubber or polyurethane outsoles with specialized tread patterns designed to channel away liquids like water and oil, ensuring a secure grip.

The effectiveness of a slip-resistant boot isn't about a single feature, but about the synergy between its outsole material and a tread design specifically engineered for the type of surface you work on.

The Foundation of Grip: The Outsole System

A boot's ability to prevent a slip happens at the point of contact with the ground. This makes the outsole—the very bottom of the boot—the most critical component for slip resistance.

Material is the Critical First Step

The outsole is almost always made from high-friction rubber or polyurethane. These materials are chosen for their natural ability to create resistance when they rub against another surface.

The specific compound used is engineered to remain pliable and grippy even when exposed to temperature changes or workplace chemicals.

The Science of Tread Design

The pattern of grooves and channels on the outsole is the tread. Its purpose is to increase surface area and effectively displace contaminants like water, mud, or oil.

Tread designs are not one-size-fits-all. Deep, aggressive lugs are ideal for rough, outdoor terrain, as they dig into soft ground for traction. Conversely, finer, more intricate tread patterns are better for smooth, indoor surfaces, as they create more contact points and channel away liquids more efficiently.

Resistance to Workplace Hazards

Standard rubber can degrade or become slick when exposed to petroleum products. For this reason, true slip-resistant work boots feature outsoles with oil- and grease-resistant properties.

This is achieved through specific material formulations or protective coatings that prevent the sole from breaking down and losing its gripping ability.

Beyond the Outsole: A Complete Safety System

While the outsole provides the primary grip, other features ensure the boot functions as a reliable piece of safety equipment. These elements contribute to durability, overall protection, and user stability.

Durability and Construction

Features like triple-stitching and polyurethane-coated leather rands are signs of a well-built boot. This robust construction ensures the boot can withstand heavy use without failing, which is critical for maintaining its structural integrity and safety performance.

Integrated Safety Components

Slip resistance is often just one part of a comprehensive safety design. Many boots integrate other protective features based on workplace requirements.

These can include steel or composite safety toes to protect against impacts, metatarsal guards, or insulation against extreme temperatures.

Comfort for Stability and Productivity

A secure fit is essential for stability. Features like cushioned insoles, supportive midsoles, and proper arch support prevent your foot from shifting inside the boot.

This not only enhances comfort over long shifts but also contributes to better balance and a more stable footing, indirectly reducing the risk of a slip or fall.

Understanding the Trade-offs

Choosing the right boot requires understanding that certain features are optimized for specific conditions, often at the expense of others.

No Single Tread Fits All Surfaces

The most common trade-off is in tread design. A boot with deep lugs designed for mud and gravel will have less surface contact on a smooth concrete floor, making it less effective on an oily spill in a garage.

You must match the tread pattern to your primary work environment.

Grip vs. Durability

Softer rubber compounds often provide the best friction and grip. However, these softer materials can wear down more quickly than harder, more durable compounds.

Manufacturers are constantly balancing this equation, but it remains a key consideration, especially for work performed on highly abrasive surfaces like concrete or asphalt.

Making the Right Choice for Your Environment

To select the most effective boot, analyze the specific hazards you face on a daily basis.

- If your primary focus is smooth, wet, or oily surfaces: Choose a boot with a fine, high-contact tread pattern and a certified oil-resistant outsole.

- If your primary focus is outdoor, uneven, or loose terrain: Prioritize a boot with deep, self-cleaning lugs designed for maximum traction on natural ground.

- If your primary focus is a combination of hazards: Look for a versatile boot that combines slip resistance with other critical safety features like a protective toe or electrical hazard rating.

Understanding how these features function allows you to choose a boot that provides genuine safety, not just the appearance of it.

Summary Table:

| Feature | Key Attribute | Benefit |

|---|---|---|

| Outsole Material | High-friction rubber or polyurethane | Provides superior grip and resists wear |

| Tread Design | Grooves and channels for liquid displacement | Maximizes surface contact and prevents slips |

| Hazard Resistance | Oil- and grease-resistant properties | Maintains traction in hazardous environments |

| Safety Components | Steel/composite toes, metatarsal guards | Offers comprehensive foot protection |

| Comfort & Stability | Cushioned insoles, arch support | Enhances balance and reduces fatigue |

Need the right slip-resistant boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of slip-resistant work boots and safety shoes, engineered for maximum traction and durability in any environment.

Contact us today to discuss your specific requirements and get a customized solution that ensures safety and performance.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What additional benefits do slip-resistant shoes offer besides slip prevention? Enhance Comfort, Safety & Productivity

- How do the structural design features of high-protection work shoes prevent falls? Stability and Gait Secrets Revealed

- What additional safety features might be required in slip-resistant work shoes? Essential Protection for Your Workplace

- What features should one look for in non-slip restaurant shoes? Find the Best for Safety & Comfort

- How can slip-resistant shoes help prevent workplace accidents? Essential Safety for High-Risk Environments

- What supplementary protection do portable anti-slip devices offer? Enhance Professional Footwear on Polished Snow

- Why might someone choose non-slip shoes over regular footwear? Ensure Workplace Safety and Stability

- What is the technical function of five-star GRIP rated footwear? Maximize Safety with Advanced Traction Engineering