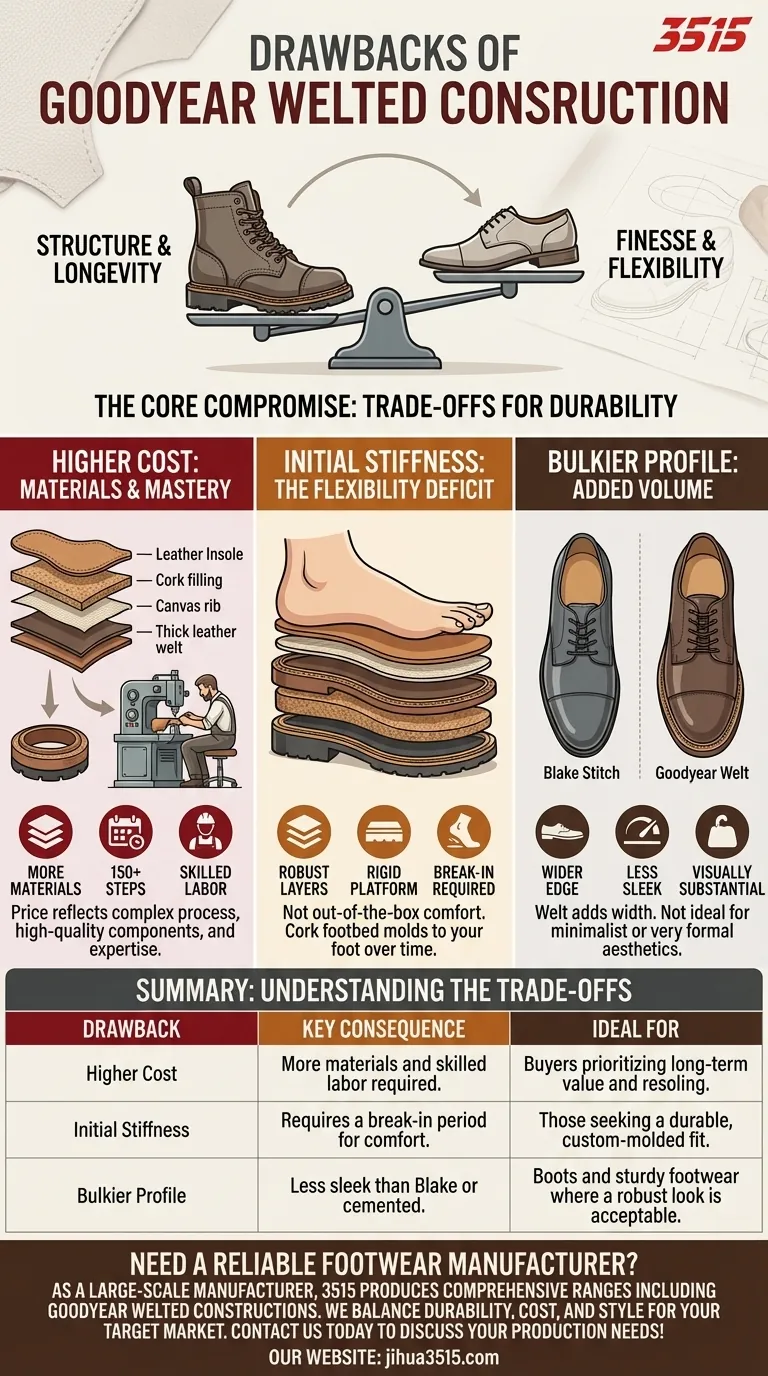

While revered for its durability, Goodyear welted construction is not without its distinct drawbacks. The primary disadvantages are its significantly higher cost, an initial lack of flexibility that requires a break-in period, and a bulkier, less sleek profile compared to other shoe construction methods. These are not flaws in the method but rather inherent consequences of its complex and robust design.

The drawbacks of a Goodyear welt are direct trade-offs for its benefits. The very features that make the shoe exceptionally durable and resoleable—multiple layers and complex stitching—are the same features that make it more expensive, initially stiff, and visually substantial.

The Core Compromise: Structure vs. Finesse

Understanding the drawbacks of a Goodyear welt requires seeing them as two sides of the same coin. The method prioritizes longevity and structure above all else, which necessarily leads to compromises in other areas.

The Cost Factor: Materials and Mastery

The most immediate drawback is the price. This isn't an arbitrary markup but a direct result of the construction process.

Goodyear welting requires more materials, including a dedicated leather welt and a cork filling, which add to the base cost.

More importantly, the process is labor-intensive, involving over 150 distinct steps and requiring highly skilled artisans to operate specialized machinery. This complexity and need for expertise are reflected in the final cost.

The Flexibility Deficit: An Initial Stiffness

A brand new pair of Goodyear welted shoes will feel noticeably stiff. This is by design.

The construction involves multiple robust layers: an insole, a canvas rib, the upper, the welt, a cork filling, and the outsole. This layered system creates a rigid platform.

While this rigidity provides excellent support, it means the shoe lacks initial flexibility. A break-in period is necessary for the leather to soften and the cork footbed to mold to the unique shape of your foot.

The Profile Problem: Added Volume

Compared to sleeker methods like the Blake stitch, a Goodyear welted shoe has a more substantial and wider profile.

The welt itself is a strip of leather stitched around the perimeter of the shoe, acting as a buffer between the upper and the outsole.

This component inherently adds width to the shoe's edge. While many appreciate this as a characteristic of a well-made, sturdy shoe, it is a clear drawback for those seeking a minimalist, low-profile, or very formal look.

Understanding the Trade-offs

A drawback is only a dealbreaker if it conflicts with your primary goal. The key is to recognize that no single construction method is universally superior; each is a set of compromises designed for a specific purpose.

The Myth of "Instant" Comfort

While Goodyear welted shoes are famous for their long-term comfort, this comfort is earned, not immediate.

The cork filling between the insole and outsole is the source of this customized fit, but it only conforms to your foot after repeated wear. Expecting out-of-the-box comfort is a common misconception.

Durability vs. Delicacy

The robust nature of the Goodyear welt makes it ideal for boots and daily-wear shoes intended to withstand years of use and multiple resoles.

However, for a delicate, formal dress shoe where a sleek silhouette is paramount, the bulk of the welt can be a significant aesthetic disadvantage. A Blake-stitched or cemented shoe might be more appropriate for that specific context.

Making the Right Choice for Your Goal

Ultimately, the "drawbacks" of a Goodyear welt are simply features that may or may not align with your needs. To make an informed decision, you must first define your priority.

- If your primary focus is maximum longevity and repairability: The higher initial cost and break-in period are a small price to pay for a shoe that can last for decades.

- If your primary focus is a sleek, form-fitting profile for formal wear: You may prefer a less bulky construction like a Blake stitch, accepting the compromise on water resistance and ease of resoling.

- If your primary focus is out-of-the-box comfort and affordability: A cemented construction may be more suitable, with the understanding that the shoe's lifespan is limited and it cannot be resoled.

Choosing the right shoe is about matching the construction method to your intended use.

Summary Table:

| Drawback | Key Consequence | Ideal For |

|---|---|---|

| Higher Cost | More materials and skilled labor required. | Buyers prioritizing long-term value and resoling. |

| Initial Stiffness | Requires a break-in period for comfort. | Those seeking a durable, custom-molded fit over time. |

| Bulkier Profile | Less sleek than Blake stitch or cemented shoes. | Boots and sturdy footwear where a robust look is acceptable. |

Need a reliable footwear manufacturer that understands construction trade-offs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including Goodyear welted constructions. We can help you select the perfect method for your target market, balancing durability, cost, and style.

Contact us today to discuss your production needs and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- What are the key factors that contribute to the quality of a dress shoe? Invest in Craftsmanship & Durability

- What are the options for waterproofing leather shoes? Protect Your Footwear for the Long Haul

- What are the disadvantages of Goodyear welt construction? A Deep Dive into the Trade-offs

- How do Derby shoes differ from Oxfords? A Guide to Choosing the Right Shoe for Any Occasion

- What kind of shoes do businessmen wear? Master the Dress Code for Professional Success

- What are the distinguishing features of Monk Strap shoes? A Guide to Sophisticated Style

- What occasions are Derby shoes best suited for? A Guide to Versatile Men's Style

- How is the sole attached in Goodyear welt construction? A Guide to Superior Durability & Repairability