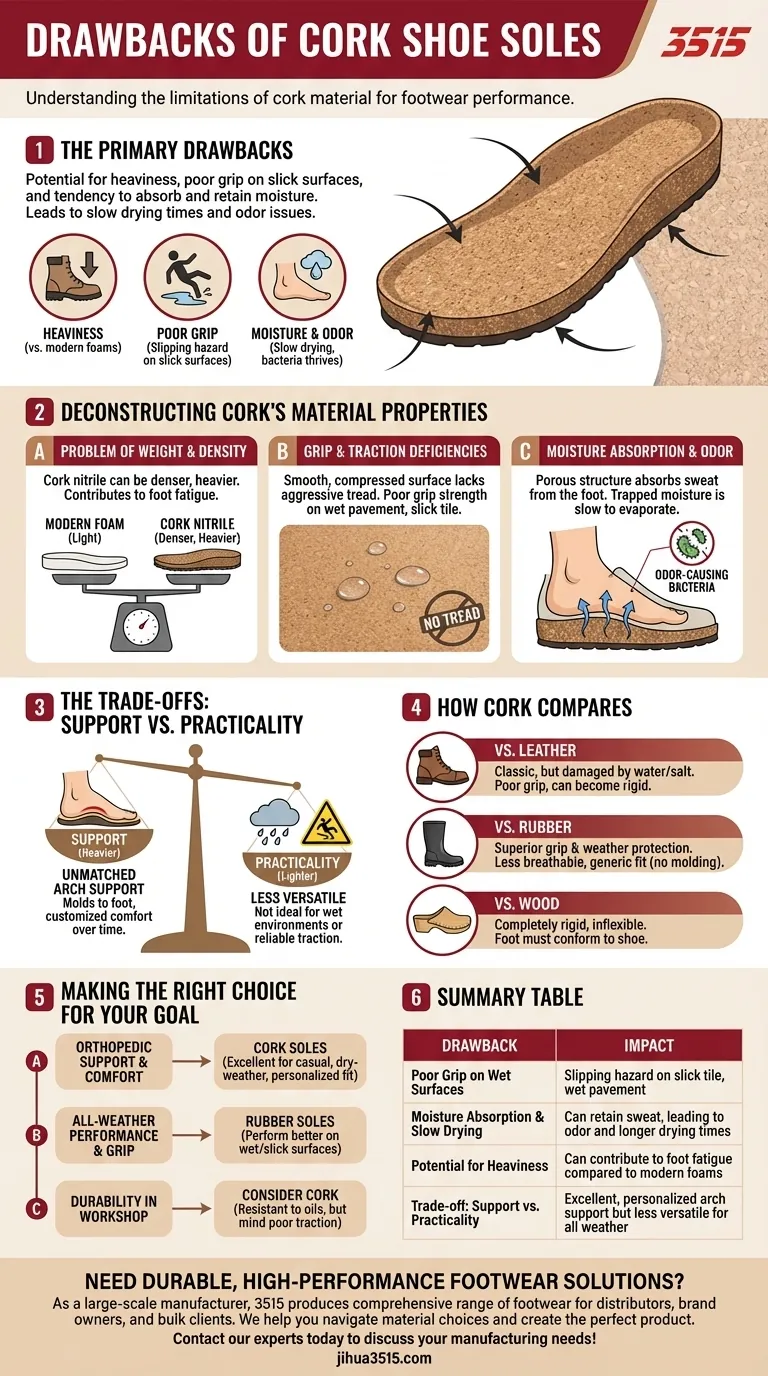

The primary drawbacks of cork shoe soles are their potential for heaviness, poor grip on slick surfaces, and their tendency to absorb and retain moisture. This can lead to significantly slow drying times and potential odor issues with consistent wear.

While cork offers excellent, personalized arch support by molding to the foot, this comfort comes at a cost. The material's inherent properties make it less practical for wet environments or situations demanding reliable traction.

Deconstructing Cork's Material Properties

To understand if cork soles are right for you, it's essential to look at the specific characteristics of the material itself and how they translate into real-world performance.

The Problem of Weight and Density

While not always the heaviest option, soles made of cork nitrile can be denser and heavier than many modern foam or synthetic composite materials. This added weight can contribute to foot fatigue over a long day.

Grip and Traction Deficiencies

Cork's smooth, compressed surface lacks a natural, aggressive tread. This results in poor grip strength, especially on wet pavement, slick tile, or other smooth surfaces, making them a potential slipping hazard.

Moisture Absorption and Odor

There is a critical distinction in how cork handles moisture. While it is naturally resistant to water penetrating from the outside, its porous structure can absorb sweat from the foot.

This trapped moisture is slow to evaporate, creating an environment where odor-causing bacteria can thrive. Shoes with cork soles require adequate time to dry out completely between wears to mitigate this.

Understanding the Trade-offs: Support vs. Practicality

No shoe material is perfect; choosing one is always an exercise in balancing competing benefits. Cork's disadvantages are offset by significant advantages in comfort and durability.

Unmatched Arch Support

The single greatest advantage of a cork sole or footbed is its ability to mold to your foot. Over time, the slightly elastic material compresses and shapes itself to your unique arches and pressure points, providing a customized level of support that is difficult to replicate.

How Cork Compares to Other Materials

Understanding the alternatives provides crucial context for cork's limitations.

- vs. Leather: Leather soles are classic but are easily damaged by water and sidewalk salt. They also offer poor grip and can become uncomfortably rigid over time.

- vs. Rubber: Rubber offers superior grip and weather protection. However, it is far less breathable than cork and does not mold to the foot, offering a more generic fit.

- vs. Wood: Wooden soles are completely rigid and inflexible. Unlike cork, they force the foot to conform to the shoe, which will never become more comfortable if the initial fit isn't perfect.

Making the Right Choice for Your Goal

Selecting footwear with cork soles depends entirely on your intended use and priorities.

- If your primary focus is orthopedic support and customized comfort: Cork is an excellent choice for casual, dry-weather footwear, as it molds perfectly to your foot over time.

- If your primary focus is all-weather performance and grip: You should choose rubber soles, as cork performs poorly on wet or slick surfaces and can be damaged by excessive moisture.

- If your primary focus is durability in a workshop environment: Cork's resistance to oils makes it a strong contender, but you must still consider the poor traction.

Ultimately, choosing a cork sole is a decision to prioritize personalized, long-term comfort over all-condition versatility.

Summary Table:

| Drawback | Impact |

|---|---|

| Poor Grip on Wet Surfaces | Slipping hazard on slick tile, wet pavement |

| Moisture Absorption & Slow Drying | Can retain sweat, leading to odor and longer drying times |

| Potential for Heaviness | Can contribute to foot fatigue compared to modern foams |

| Trade-off: Support vs. Practicality | Excellent, personalized arch support but less versatile for all weather |

Need Durable, High-Performance Footwear Solutions?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the right balance of comfort, durability, and performance for your market.

Let us help you navigate material choices and create the perfect product for your customers.

Contact our experts today to discuss your manufacturing needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites