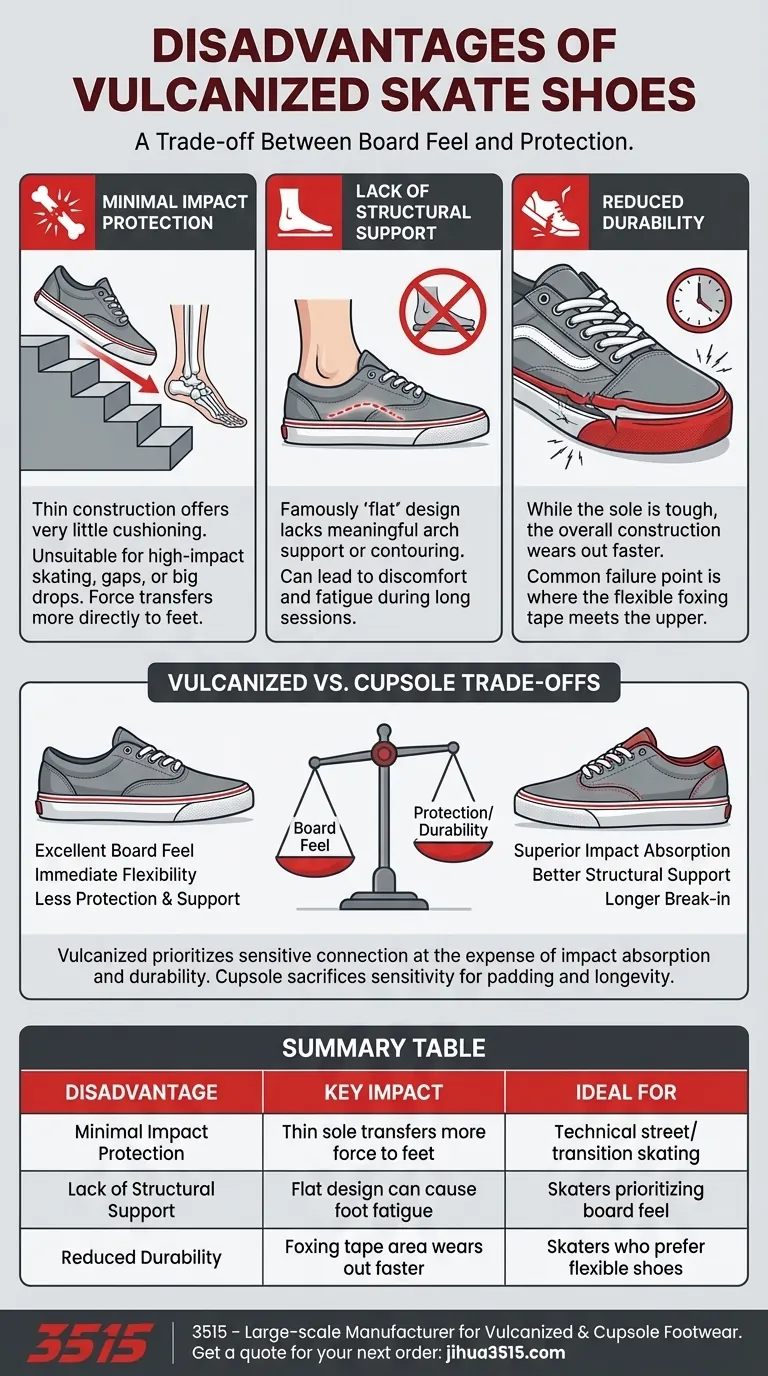

The primary disadvantages of vulcanized skate shoes are a direct result of their thin, flexible construction. They inherently offer less impact protection, minimal foot support, and tend to wear out faster than their more structured counterparts, making them a poor choice for high-impact skateboarding.

The decision to use a vulcanized shoe is a fundamental trade-off between board feel and foot protection. Vulcanized construction prioritizes a sensitive, flexible connection to your board at the direct expense of impact absorption, structural support, and overall durability.

The "Why" Behind the Weakness: Construction Defines Performance

To understand the disadvantages of a vulcanized shoe, you must first understand how it's made. The design philosophy behind this shoe directly creates its specific set of limitations.

A Process of Heat and Adhesion

A vulcanized shoe's sole is attached to its upper using a strip of rubber called foxing tape. The entire shoe is then heated in an oven, a process that bonds the rubber components together into a single, cohesive piece.

The Source of "Board Feel"

This heating process results in a very thin, flat, and flexible sole. This construction is what gives vulcanized shoes their legendary board feel—the feeling of being connected to your board, almost as if skating barefoot.

The Core Drawbacks Explained

The very features that create excellent board feel are also the source of every major disadvantage. The thin, flexible sole simply cannot provide the same level of performance in other key areas.

Minimal Impact Protection

The thin layer of rubber offers very little cushioning. This makes vulcanized shoes unsuitable for skating large stair sets, gaps, or anything involving significant impact, as the force is transferred more directly to your feet.

Lack of Structural Support

Vulcanized shoes are famously "flat." They typically lack any meaningful arch support or contouring for your foot, which can lead to discomfort and fatigue during long sessions, especially for skaters who need more support.

Reduced Durability

While the sole itself is durable, the overall shoe construction wears out faster. The most common point of failure is where the flexible foxing tape meets the upper material of the shoe, which endures constant stress during skating.

Understanding the Trade-offs: Vulcanized vs. Cupsole

The main alternative to a vulcanized shoe is a cupsole, which features a thicker, stitched sole that cradles the foot. The choice between them is a classic engineering trade-off.

Board Feel vs. Protection

A vulcanized shoe provides unparalleled board feel, essential for technical tricks. A cupsole sacrifices this sensitivity for thick padding and superior impact absorption.

Flexibility vs. Longevity

The vulcanized shoe's flexibility allows for immediate comfort and control right out of the box. The more rigid cupsole takes longer to break in but offers a more durable, long-lasting construction.

Mitigating the Downsides

While you cannot change the shoe's core construction, the lack of support and impact protection can be partially mitigated. Using high-quality aftermarket insoles can add crucial cushioning and arch support to an otherwise flat shoe.

Making the Right Choice for Your Skating

Your decision should be based entirely on your primary style of skateboarding and what you demand from your equipment.

- If your primary focus is technical street or transition skating: The superior board feel and flexibility of vulcanized shoes are likely worth the trade-offs in protection.

- If your primary focus is high-impact skating (stairs, gaps, big drops): You should strongly consider a cupsole shoe for its necessary impact protection and structural support.

- If you are prone to foot pain or need more arch support: A cupsole is the safer choice, though a vulcanized shoe with a premium insole can be a viable compromise.

Understanding this core trade-off empowers you to choose the right tool for your feet and your skating.

Summary Table:

| Disadvantage | Key Impact | Ideal For |

|---|---|---|

| Minimal Impact Protection | Thin sole transfers more force to feet | Technical street/transition skating |

| Lack of Structural Support | Flat design can cause foot fatigue | Skaters prioritizing board feel |

| Reduced Durability | Foxing tape area wears out faster | Skaters who prefer flexible shoes |

Need durable skate shoes for bulk orders? As a large-scale manufacturer, 3515 produces a comprehensive range of vulcanized and cupsole footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure the right balance of board feel, protection, and durability for your market. Get a quote for your next order: Contact 3515 Factory Today.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What protective role does the sole structure of toe spring shoes play? Master Complex Terrain and Prevent Falls

- What are some alternatives to hunting boots? Hiking, Rubber & Tactical Boots Explained

- What are the characteristics of heavy-duty hiking boots? Ultimate Guide for Rugged Terrain

- What is a trekking shoe? The Essential Guide to Protection & Stability

- What technical requirements are essential for outsoles in pivoting sports? Boost Grip and Lateral Stability